7 Warehouse Picking Strategies To Speed Up The Process

7 Warehouse Picking Strategies To Speed Up The Process Conveyor belts. computer systems. mobile robots, in some cases. learning how to use these tools can help you speed up your picking and propel your career forward. 4. zone picking method. another well known order picking process you might encounter or decide to implement is known as zone picking or pick and pass. Discrete picking: in terms of complexity, discrete picking is one of the most straightforward warehouse picking types to implement. pickers retrieve one order at a time, completing it entirely before moving on to the next. this strategy is especially effective for small operations with low sku count and limited warehouse space.

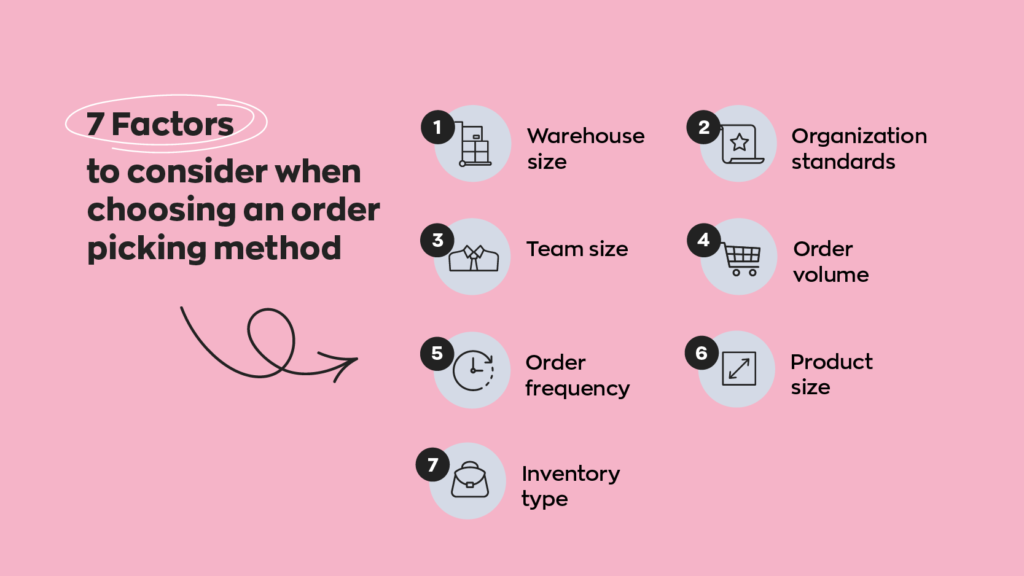

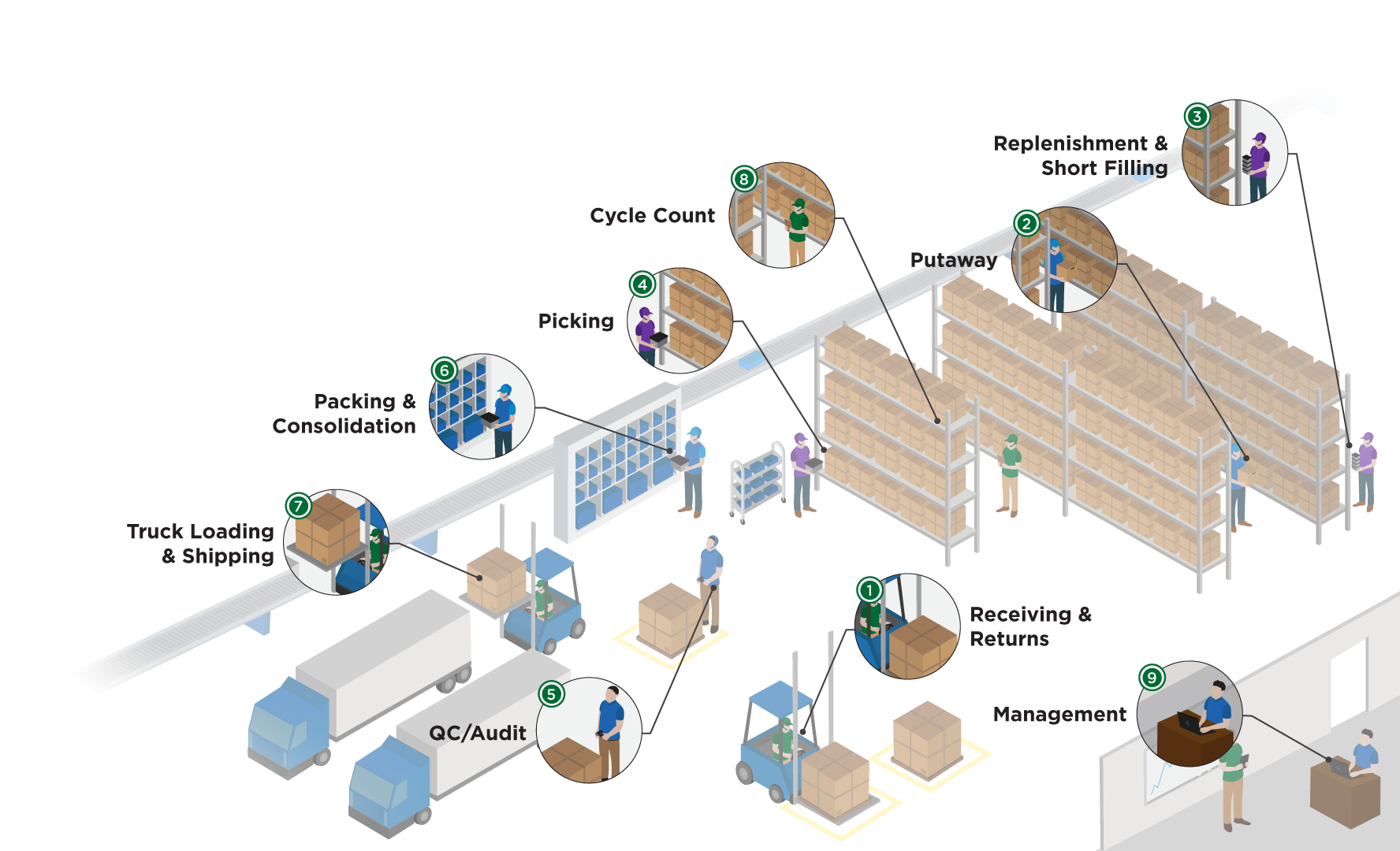

Warehouse Picking Strategies Guide These are the seven most popular picking methods in the order fulfillment process. which method you should choose varies according to the layout of your warehouse and the types of products you ship. 1. zone picking. zone picking is a popular picking strategy. to implement this picking method, you must divide the warehouse into zones and. Software driven order picking methods. 1. wave picking. wave picking works by grouping orders into a batch, which is released for picking in a single wave. the name comes from the motion of pickers working from one end of a facility to the other end, much as a wave travels across a surface. The most time consuming part of the order picking process is traveling, which takes up 55% of the warehouse selector’s time, on average, followed by paperwork and other activities (20%), searching (15%) and extracting (10%), according to research from the georgia tech supply chain and logistics institute. Optimized picker routes and holistic order picking strategies will lead to fewer customer order returns for your warehouse operations. human errors in warehouse picking. human errors will always be a possibility for warehouse operations, especially in the order picking process which requires a significant amount of human output.

7 Warehouse Picking Strategies To Improve Efficiency The most time consuming part of the order picking process is traveling, which takes up 55% of the warehouse selector’s time, on average, followed by paperwork and other activities (20%), searching (15%) and extracting (10%), according to research from the georgia tech supply chain and logistics institute. Optimized picker routes and holistic order picking strategies will lead to fewer customer order returns for your warehouse operations. human errors in warehouse picking. human errors will always be a possibility for warehouse operations, especially in the order picking process which requires a significant amount of human output. Both strategies require careful planning, but improve order accuracy and make it easier to be a faster warehouse picker. effective slotting techniques contribute to a well organized inventory, boosting speed and accuracy in ecommerce order fulfillment. 3. establishing efficient picking routes. This way, you speed up your customer deliveries, apart from freeing up your warehouse personnel to focus more on other critical tasks. here are the top 15 tips to help hasten the picking process in your warehouse: optimize warehouse layout. execute the right picking methods. strategize slotting strategies.

How To Choose The Best Warehouse Order Picking Method Both strategies require careful planning, but improve order accuracy and make it easier to be a faster warehouse picker. effective slotting techniques contribute to a well organized inventory, boosting speed and accuracy in ecommerce order fulfillment. 3. establishing efficient picking routes. This way, you speed up your customer deliveries, apart from freeing up your warehouse personnel to focus more on other critical tasks. here are the top 15 tips to help hasten the picking process in your warehouse: optimize warehouse layout. execute the right picking methods. strategize slotting strategies.

Warehouse Order Picking Strategies To Optimize Dc Operations

Warehouse Picking Strategies How To Improve Order Fulfillment

Comments are closed.