Air Cooled Chiller Process Flow Diagram

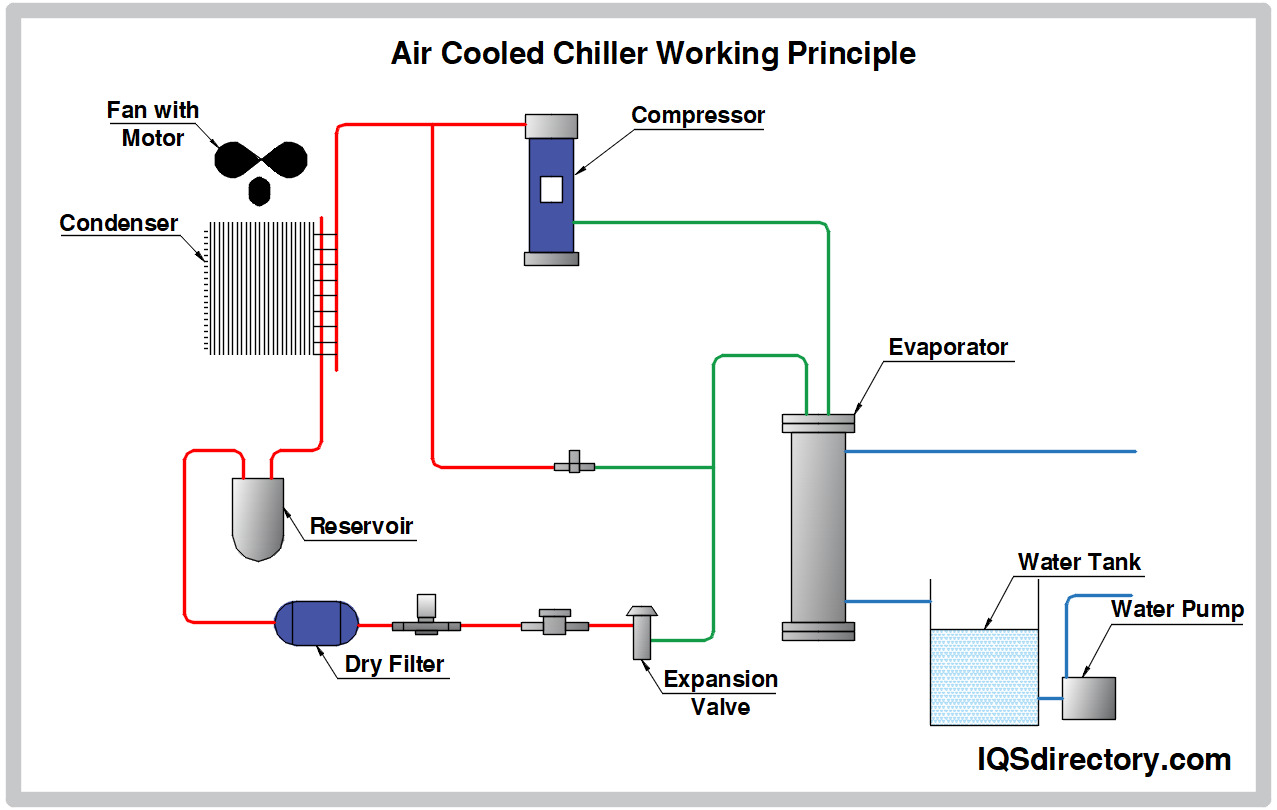

The Basics Of Chillers Hvac Investigators The air cooled condenser is a heat exchanger where the process heat absorbed by the refrigerant is given off to the air around it. as heat is given off by the high temperature high pressure vapor, its temperature falls until the vapor condenses to a liquid. a centrifugal blower or motor driven fans generate airflow across the condenser. 1. air cooled chiller design data. in this tutorial, we’re going to be taking a look at air cooled chillers to find out how they work in a more advanced way. we’re going to be taking a look at the refrigerant this time and the pressures, temperature, enthalpy, entropy, flow rates and heat transfer. scroll to the bottom to watch the.

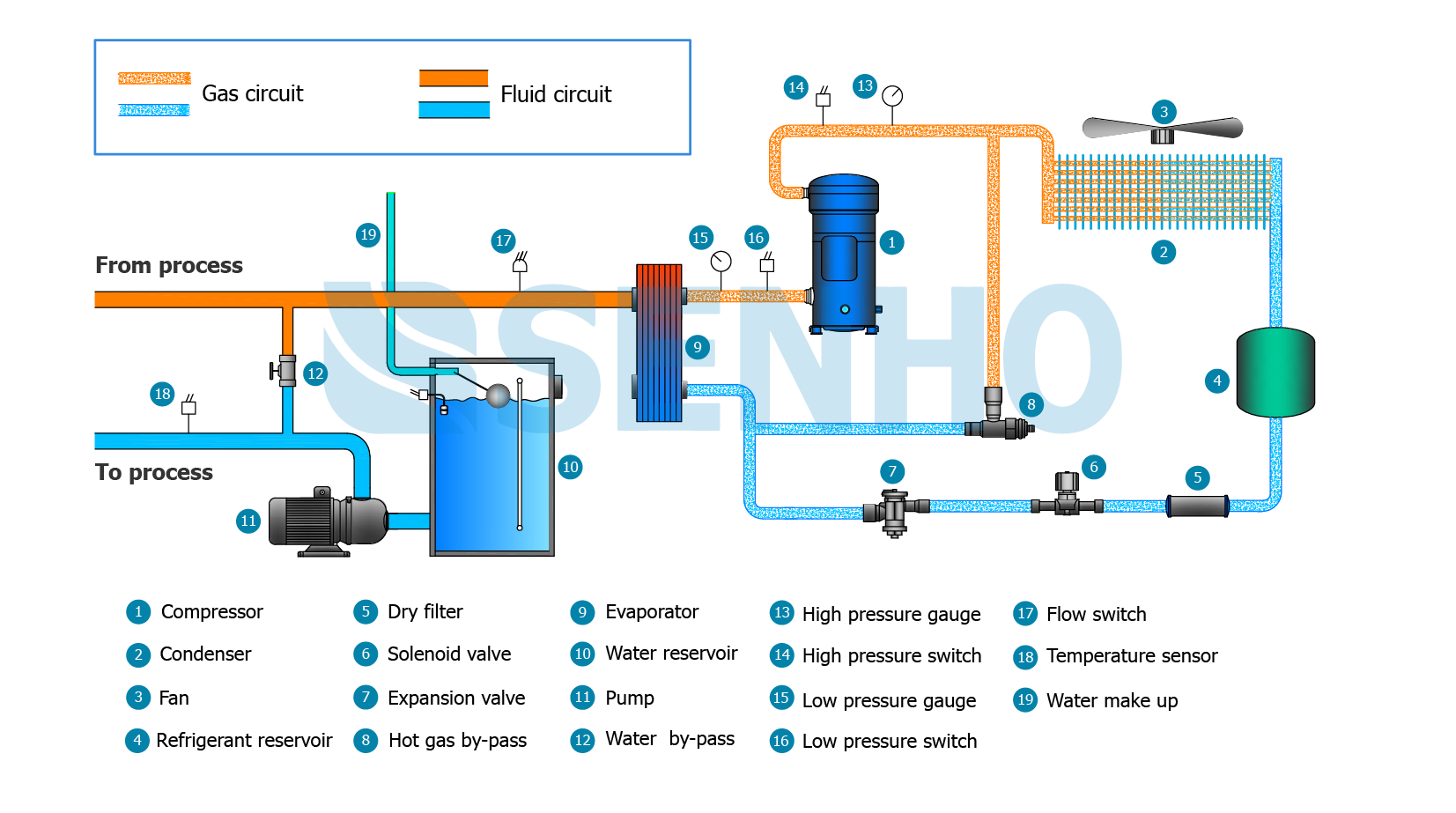

Air Cooled Chiller Schematic Diagram In this article we’l be covering chilled and condenser water schematics to learn how to read them, how to identify the main components and symbols as well as real world examples, additionally we’ll cover the purpose of the main components and different design types. scroll to the bottom to watch the video tutorial. Rate of flow variation before varying the flow through the evaporator in a chiller. flow variation is discussed in detail in the section “variable primary flow systems” on page 55. water cooled condenser to cool a building or process, the transferred heat must ultimately be rejected outdoors or to another system (heat recovery). Sure setpoint or chilled water setpoint.select chiller for 2 to 4°f lower supply chilled water temperature than the cooling coils, to allow supply temperature reduction compensation for. irside low Δt or increased system load.install pressure independent cooling coil control valves to preserve system. It changes its pressure, temperature, enthalpy and entroy as it moves around the machine and transports the unwanted heat away from the evaporator chilled water. the air cooled chiller has 5 main components. the compressor – typically screw, scroll or reciprocating. the condenser – a bundle of horizontal pipes which contain the hot.

How Air Cooled Chiller Works With Diagram At Morgan Marguez Blog Sure setpoint or chilled water setpoint.select chiller for 2 to 4°f lower supply chilled water temperature than the cooling coils, to allow supply temperature reduction compensation for. irside low Δt or increased system load.install pressure independent cooling coil control valves to preserve system. It changes its pressure, temperature, enthalpy and entroy as it moves around the machine and transports the unwanted heat away from the evaporator chilled water. the air cooled chiller has 5 main components. the compressor – typically screw, scroll or reciprocating. the condenser – a bundle of horizontal pipes which contain the hot. Creating an air cooled chiller piping diagram is an essential part of the design process for any air conditioning system. this diagram acts as a visual representation of how the piping network of the chiller system will be laid out, including the placement of the chiller unit, valves, pumps, and other components. Download scientific diagram | flow chart of the air cooled water chiller components. from publication: development of a water mist cooling system: a 12,500 kcal h air cooled chiller | global.

Air Cooled Water Chillers Air Cooled Type Chillersä Senho Chiller Creating an air cooled chiller piping diagram is an essential part of the design process for any air conditioning system. this diagram acts as a visual representation of how the piping network of the chiller system will be laid out, including the placement of the chiller unit, valves, pumps, and other components. Download scientific diagram | flow chart of the air cooled water chiller components. from publication: development of a water mist cooling system: a 12,500 kcal h air cooled chiller | global.

Schematic Diagram Of Air Cooled Chiller System In Hospital Langkawi

Air Cooled Chiller Diagram

Comments are closed.