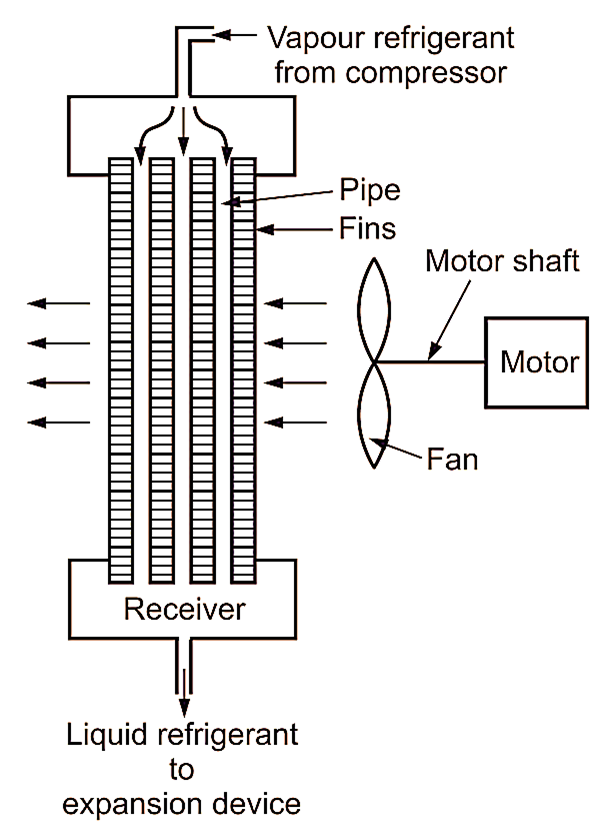

Air Cooled Condenser Diagram

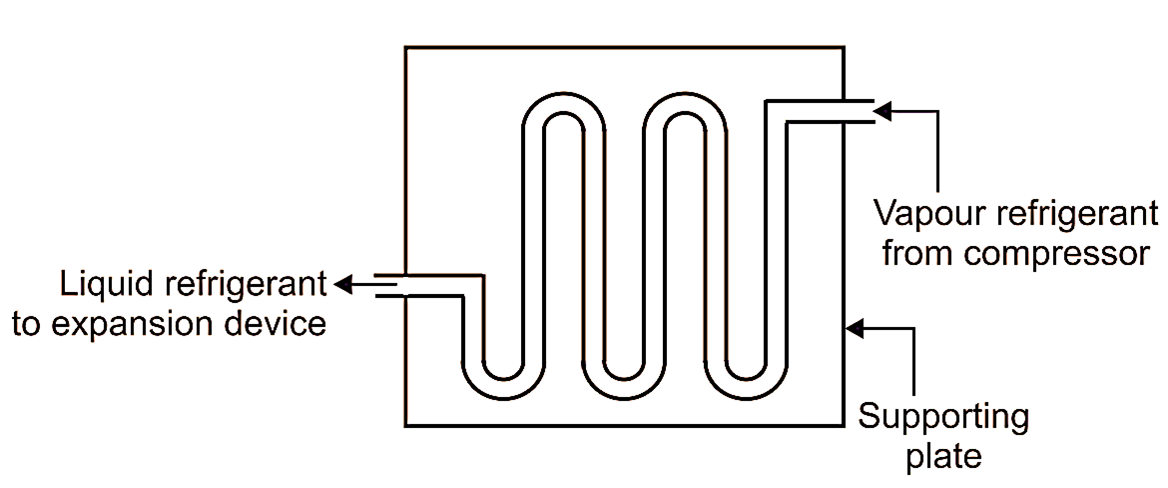

What Is Air Cooled Condenser Working Types Diagram Electricalworkbook In conclusion, an air cooled condenser diagram provides a visual representation of the components and system of an air cooled condenser, helping to understand its operation and performance. it includes various key components such as condenser coils, fan, air inlet, and air outlet, as well as other components like the compressor, expansion valve. Working, types & diagram. an air cooled condenser is one, in which, the removal of heat is done by air (cooling medium). it consists of steel or copper tubing, through which, the refrigerant flows. the size of tube usually ranges from 6 mm to 18 mm outside diameter, depending upon the size of condenser. generally copper tubes are used, because.

What Is Air Cooled Condenser Working Types Diagram Electricalworkbook Tags. an air cooled condenser (acc) is a direct dry cooling system where steam is condensed inside air cooled finned tubes. the cool ambient air flow outside the finned tubes is what removes heat and defines the functionality of an acc. in thermal power plants (t), the steam from the turbine exhaust flows into the acc where condensation occurs. Air cooled condenser design, specification, and operation guidelines 15133525. 15133525. epri project manager k. zammit electric power research institute. Air cooled condensers provide flexibility in system placement as they are not dependent on proximity to a water source. this flexibility is valuable in designing systems for various environments. reduced maintenance complexity: air cooled condensers generally have simpler maintenance requirements compared to water cooled systems. In single or multifamily residences, air cooled condensers are used in place of the larger cooling towers or evaporative condensers. the noise from these units is due to the fan, usually a propeller type, with a small contribution from the air flow through the condenser coil decks. figure 13.5 shows a sketch and measured data.

16 Configuration Of An A Frame Air Cooled Condenser Adapted From 132 Air cooled condensers provide flexibility in system placement as they are not dependent on proximity to a water source. this flexibility is valuable in designing systems for various environments. reduced maintenance complexity: air cooled condensers generally have simpler maintenance requirements compared to water cooled systems. In single or multifamily residences, air cooled condensers are used in place of the larger cooling towers or evaporative condensers. the noise from these units is due to the fan, usually a propeller type, with a small contribution from the air flow through the condenser coil decks. figure 13.5 shows a sketch and measured data. A common occurrence is a sudden crack in the condenser shell. if the air ingress is greater than can be handled by the air removal system, the excess air will form pockets in the condenser and significantly restrict heat transfer. a good cf program will often detect such problems very quickly. circulating pump discharge pressure. Download scientific diagram | the structure of the air cooled condenser (acc). from publication: numerical investigation on the influence of mechanical draft wet cooling towers on the cooling.

Comments are closed.