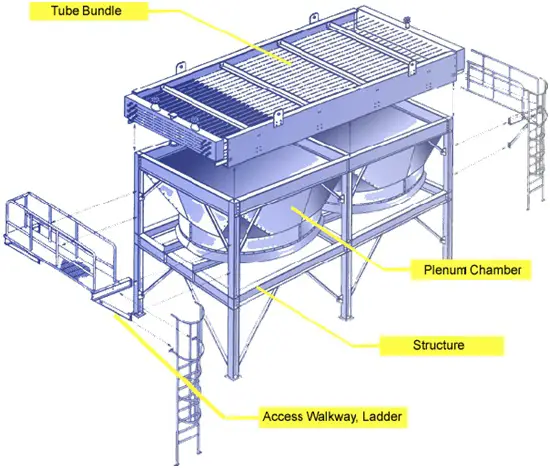

Air Cooled Heat Exchanger Diagram

Air Cooled Heat Exchangers Ache What Is Piping An air cooled heat exchanger is a heat rejection equipment that transfers excess heat from a process fluid to the ambient air. it works on the principle of convection and conduction to dissipate heat from process fluid to air. unlike water cooled heat exchangers, which use water as a cooling medium, aches use air to dissipate heat. The ratio of extended to prime surface varies from 7:1 to 25:1. bundles are rectangular and typically consist of 2 to 10 rows of finned tubes arranged on triangular pitch. bundles may be stacked in depths of up to 30 rows to suit unusual services. the tube pitch is usually between 2 and 2.5 tube diameters.

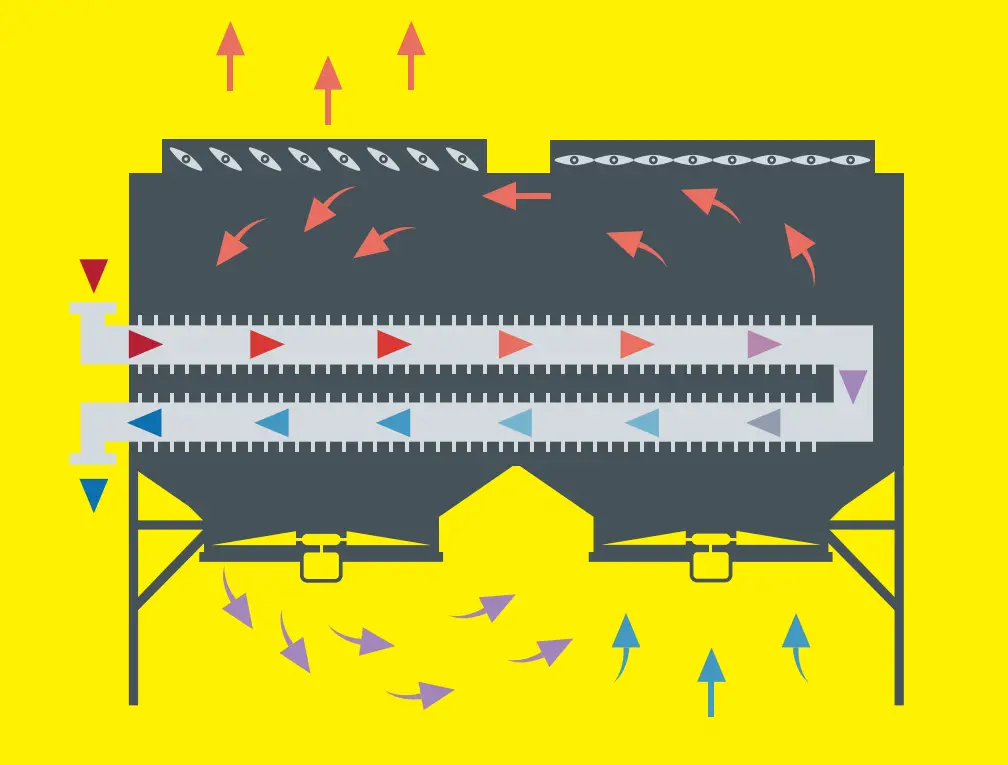

What Is An Air To Air Heat Exchanger T 1 = air inlet temperature (c) t 2 = air outlet temperature (c) w = flowrate of the fluid to cool (lb h) c = specific heat of the fluid to cool. t 1 = inlet temperature of the fluid to cool (c) t 2 = outlet temperature of the fluid to cool (c) 8. step 8 : verify if the calculated heat exchanger is sufficient. The principal performance parameters for all three total air flow rates are shown in table 2.1b. it will be seen that there is a significant reduction in the overdesign with a lowering in the air flow rate, from 6.2% in the first case to –2.9% in the second case, and finally to –13.7% in the third case. Heat exchangers take the energy from a hot stream and use it to heat a cooler stream. most of the heat exchangers used in industry are shell and tube, air cooled, or plate and frame. the table of contents below links to different types of heat exchangers. each type of equipment usually has sections on general information, information about. 1) the exchanger consists of a large outer shell (light gray) with tubes running through it (dark gray). 2) a hot fluid enters the tubes from the top left and exits from the bottom right. 3) a cooler fluid passes the opposite way through the shell, entering at the bottom right and exiting at the top left.

Air Cooled Heat Exchangers Ache What Is Piping Heat exchangers take the energy from a hot stream and use it to heat a cooler stream. most of the heat exchangers used in industry are shell and tube, air cooled, or plate and frame. the table of contents below links to different types of heat exchangers. each type of equipment usually has sections on general information, information about. 1) the exchanger consists of a large outer shell (light gray) with tubes running through it (dark gray). 2) a hot fluid enters the tubes from the top left and exits from the bottom right. 3) a cooler fluid passes the opposite way through the shell, entering at the bottom right and exiting at the top left. Water flowing at a rate of 0.723 enters the inside of a countercurrent, double pipe heat exchanger at 300.k and is heated by an oil stream that enters at 385 at a rate of. 3.2 . the heat capacity of the oil is 1.89 , and the average heat capacity of the water of the temperature range of interest is 4.192 . Consequently, when further heat integration within the plant is not possible, it is now usual to reject heat directly to the atmosphere, and a large proportion of the process cooling in refineries and chemical plants takes place in air cooled heat exchangers (aches). there is also increasing use of air cooled condensers for power stations.

2 1 Air Cooled Heat Exchanger Liquid To Gas Apiste Apiste Water flowing at a rate of 0.723 enters the inside of a countercurrent, double pipe heat exchanger at 300.k and is heated by an oil stream that enters at 385 at a rate of. 3.2 . the heat capacity of the oil is 1.89 , and the average heat capacity of the water of the temperature range of interest is 4.192 . Consequently, when further heat integration within the plant is not possible, it is now usual to reject heat directly to the atmosphere, and a large proportion of the process cooling in refineries and chemical plants takes place in air cooled heat exchangers (aches). there is also increasing use of air cooled condensers for power stations.

Comments are closed.