Amie Exam Lectures Material Design Continuous Cooling Transformation Diagram 9 3

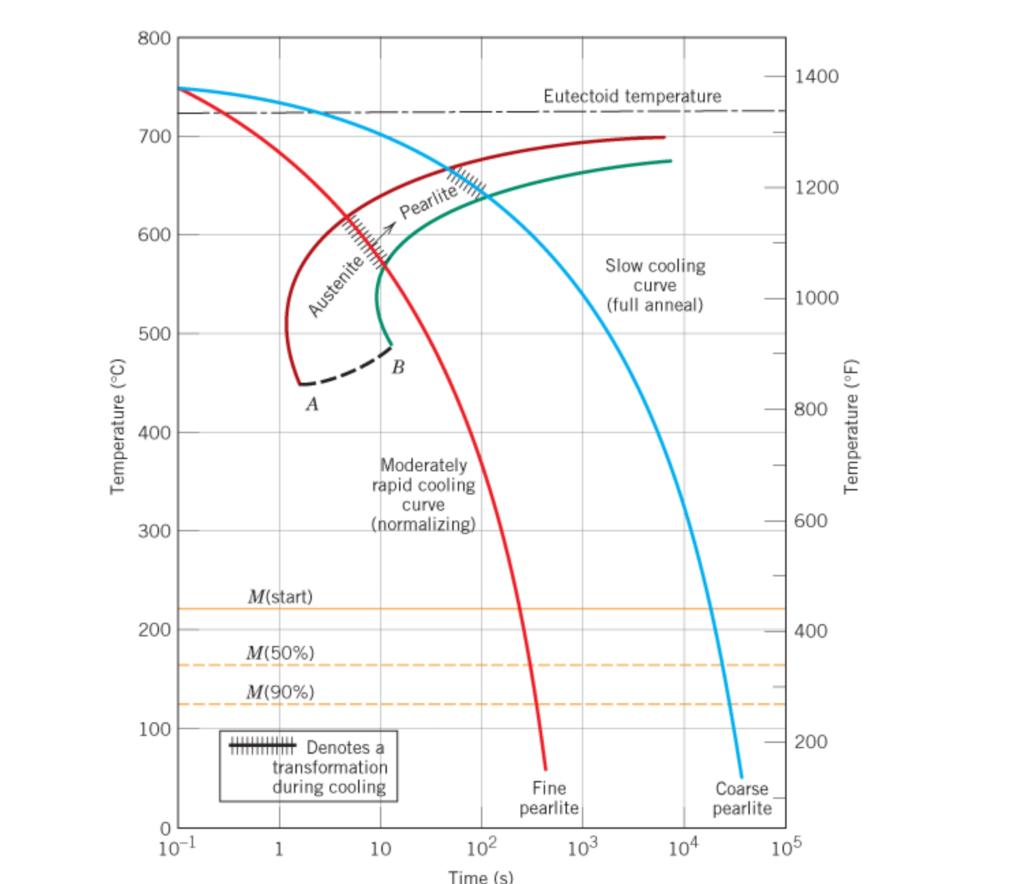

Continuous Cooling Transformation Diagram Engineering subjects: material science and engineering:material science | material design part 3 | continuous cooling transformation diagram | cct 9.3int. Definition: stability of phases during continuous cooling of austenite. there are two types of cct diagrams. i) plot of (for each type of transformation) transformation start, specific fraction of transformation and transformation finish temperature against transformation time on each cooling curve.

Continuous Cooling Transformation Diagram The critical cooling rate is the rate of cooling that is fast enough to transform austenite into 100% martensite. in welding, this can be achieved by quenching the weld in water or oil. critical cooling rates are important because they help to prevent welds from cracking. when austenite transforms into martensite too slowly, it can cause the. Construction of continuous cooling transformation (cct) diagram lecture 3 part 1 heat treatment lecture series on heat treatmentplaylist for heat treatment c. This atlas is a collection of continuous cooling transformation diagrams applicable to low carbon low alloy weld metals. it will be of assistance to welding engineers, welding metallurgists, welding consumables designers in industry. table of contents. According to references [8] [9] [10], local ferrite transformation can only be performed at a high transformation start temperature (ar3). in this paper, the cooling rate of 0.45% carbon steel.

Schematic Illustration Of Continuous Cooling Transformation Cct This atlas is a collection of continuous cooling transformation diagrams applicable to low carbon low alloy weld metals. it will be of assistance to welding engineers, welding metallurgists, welding consumables designers in industry. table of contents. According to references [8] [9] [10], local ferrite transformation can only be performed at a high transformation start temperature (ar3). in this paper, the cooling rate of 0.45% carbon steel. The continuous cooling transformation (cct) diagram of steels is very important in considering the phase transformation depending on the cooling rate of a material, however, it is difficult to. The cooling rates obtained by the jominy test can be correlated to different geometries as indicated previously. other methods include dilatometry. one method of experimentally determining the continuous transformation behavior, is air cooling bars from the austenitizing temperature, and examining the developed microstructure.

Comments are closed.