Cheese Processing Equipment Natec Network Freepack System Filling Forming Of Iws Cheese

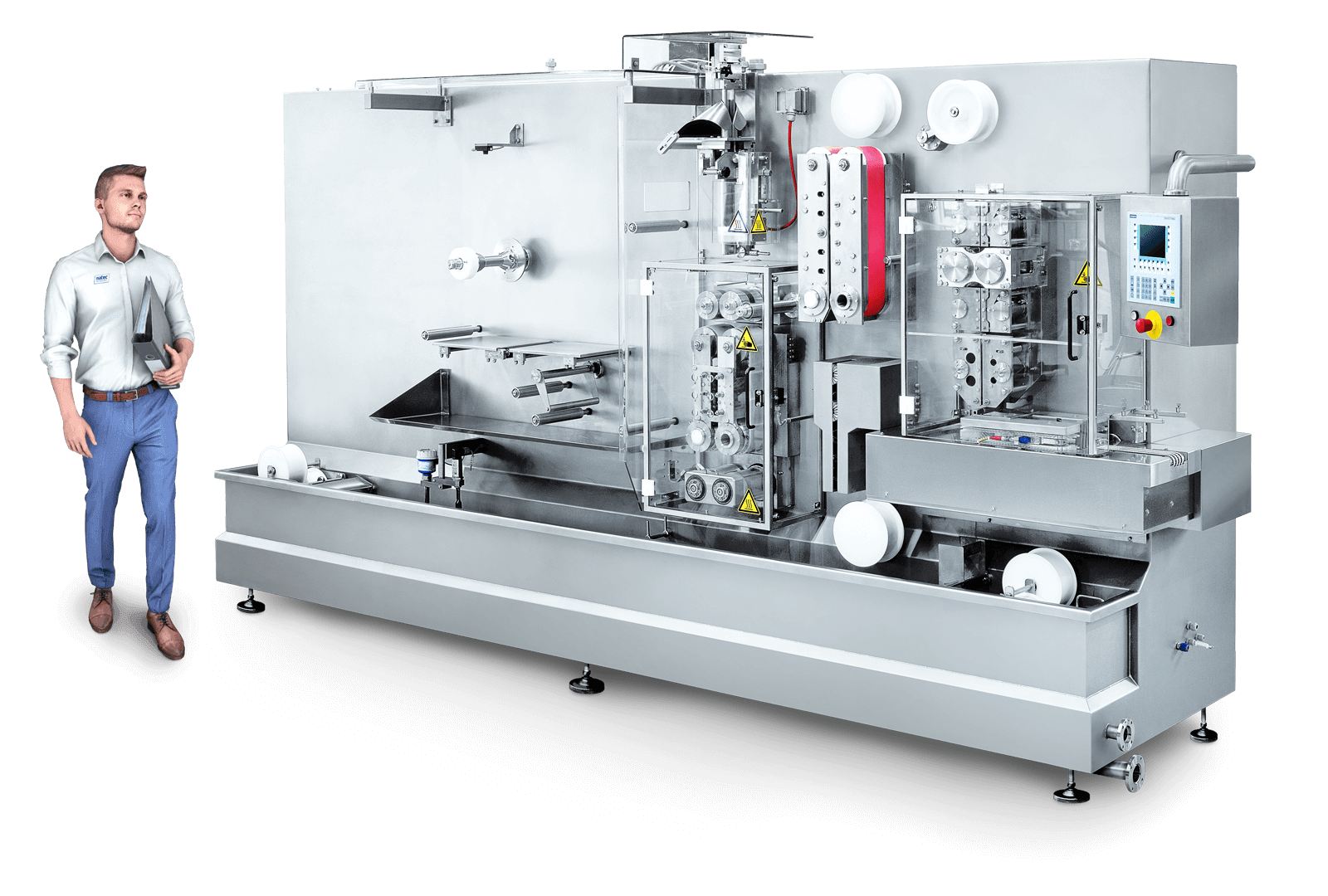

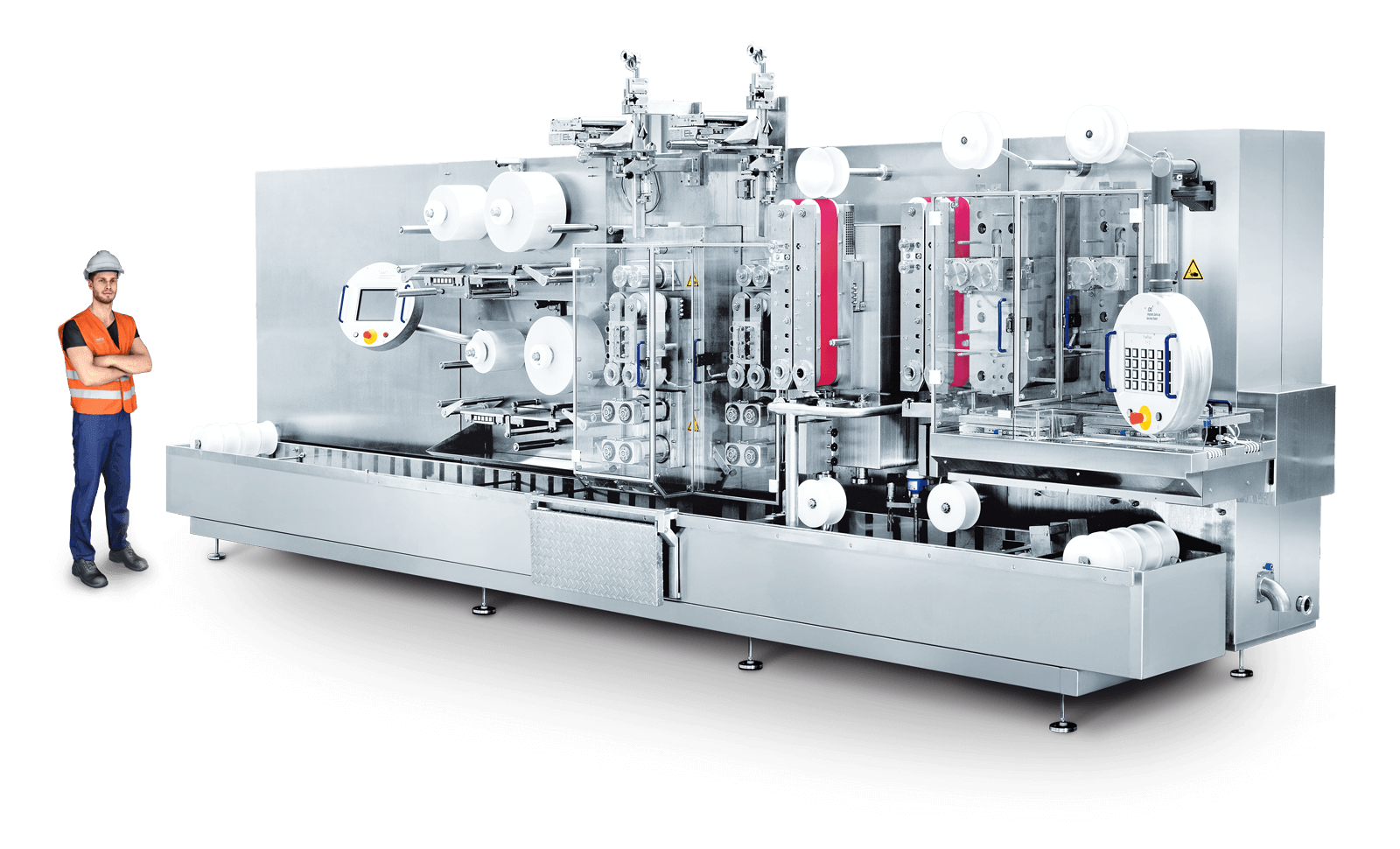

Cheese Processing Equipment Natec Network Freepack System Filling The natec freepack® machine produces individually wrapped processed cheese slices (iws) using a continuously operating production method. wrapping is perform. The natec network freepack® 2000 machine produces individually wrapped processed cheese slices (iws) using a continuously operating production method. wrapping is performed without risk of recontamination using the hot fill system. the pp foil used is environmentally friendly and recycable. exact sealing ensures the product is securely wrapped.

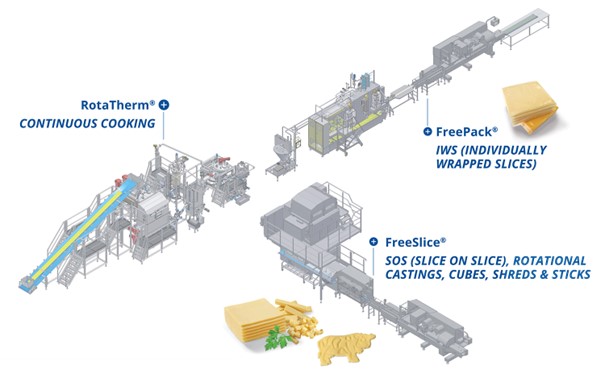

Freepack 500 Natec Network Natec’s freepack 1000 can process 1000 iws slices per minute, utilising compressed air and fresh water for cooling. it can package stacks of 3 – 25 slices, with a maximum stacking height of 75mm. the slice weight is infinitely adjustable from 13g – 30g depending on the cheese texture. the freepack is available in two other sizes:. The natec network freepack: producing individually wrapped processed cheese slices (iws) using a continuously operating production method. the natec network freeslice: it is designed to produce slice on slice cheese as well as with different applications cubes, shreds and sticks made of processed cheese, analogue or hybrid cheese. The natec network is the joining of » gold peg who design & manufacture leading edge cooking technology. rotatherm® continuous cooking system; freetherm batch cooking and processing system » hochland natec who deliver innovative iws and sos processed cheese forming and filling equipment of the. freepack for filling individually wrapped. The natec network freepack® 1000 machine produces individually wrapped processed cheese slices (iws) using a continuously operating production method. wrapping is performed without risk of recontamination using the hot fill system. the pp foil used is environmentally friendly and recycable.

Fastest Cheese Slice Wrapper Iws Machine Freepack 2000 Natec Network The natec network is the joining of » gold peg who design & manufacture leading edge cooking technology. rotatherm® continuous cooking system; freetherm batch cooking and processing system » hochland natec who deliver innovative iws and sos processed cheese forming and filling equipment of the. freepack for filling individually wrapped. The natec network freepack® 1000 machine produces individually wrapped processed cheese slices (iws) using a continuously operating production method. wrapping is performed without risk of recontamination using the hot fill system. the pp foil used is environmentally friendly and recycable. Today, the natec network builds cheese processing equipment of all types and sizes. we can provide grinders, conveyors, blenders, cookers (continuous & batch), filters, formers, cutters, wrapping machines, stackers, separators, and everything else you could need in a cheese production line. our cheese cookers can cook up to 17,000kg (17 tons. The natec freeslice® system produces slice on slice (sos) products. it is designed to produce slice on slice cheese as well as with different applications.

Making Processed Cheese Slice On Slice Natec Network Freeslice Today, the natec network builds cheese processing equipment of all types and sizes. we can provide grinders, conveyors, blenders, cookers (continuous & batch), filters, formers, cutters, wrapping machines, stackers, separators, and everything else you could need in a cheese production line. our cheese cookers can cook up to 17,000kg (17 tons. The natec freeslice® system produces slice on slice (sos) products. it is designed to produce slice on slice cheese as well as with different applications.

World Leading Processed Cheese Technology Natec Network

Comments are closed.