Conical Slicing A Different Angle Of 3d Printing

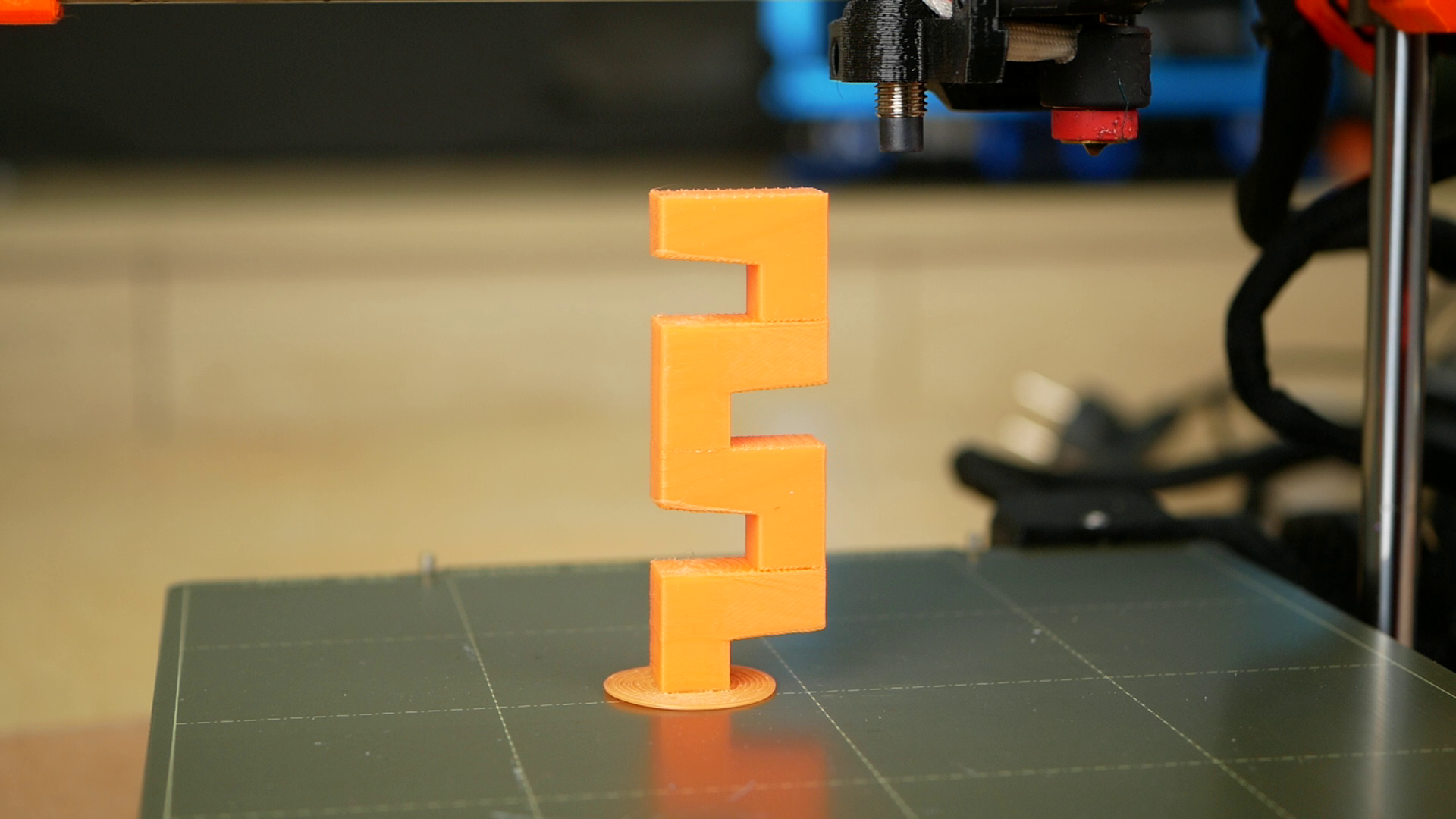

Conical Slicing A Different Angle Of 3d Printing Youtube This way you can print even these extreme geometries without the need for supports. the conical slicing approach, which stems from the rotbot project, even improves this concept and tilts the printing layers around a central axis and therefore forms a cone. since we’ll be printing our parts on a regular printer instead of one with a tilted. Current 3d printing slicers are dumb and only generate g codes on a 2 dimensional plane. we are leaving a ton of potential on the table because 3d printers a.

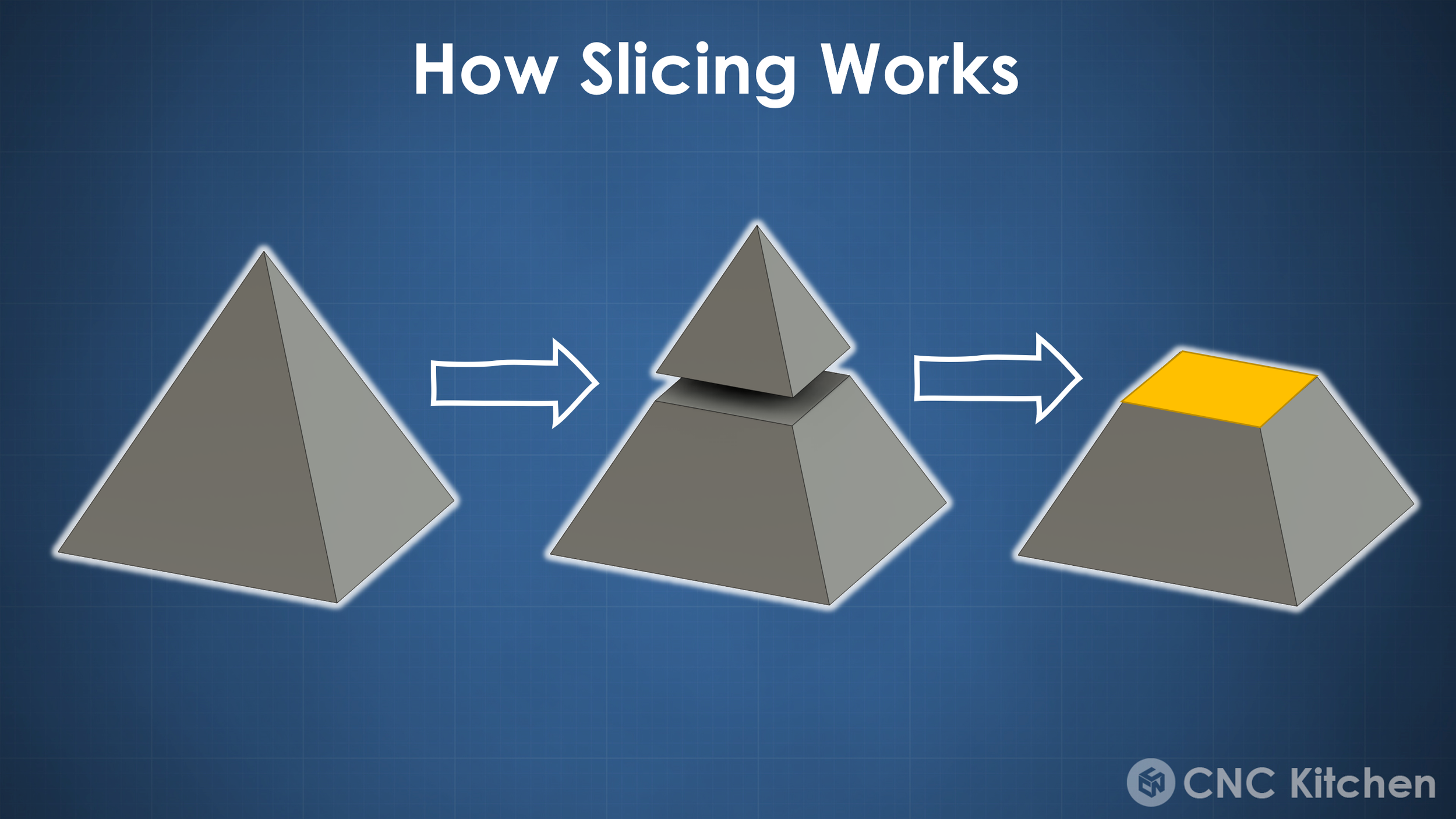

Conical Slicing A Different Angle Of 3d Printing Cnc Kitchen Refined mesh in fusion360 with 0.5 mm maximum edge length. import your stl into the slicer. the z axis of the slicing coordinate system will later be our conical axis. move the part so that the cone axis is where you want it. now we need to use a stupid workaround because prusaslicer has an unfixed bug and will always calculate it’s own model. Current 3d printing slicers are dumb and only generate g codes on a 2 dimensional plane. we are leaving a ton of potential on the table because 3d printers are easily capable of complex 3 dimensional moves, yet we don’t have any software to take advantage of it. this video shows the conical slicing approach to create non planar g code that. A normal slicer intersects the 3d model to be printed with a 2d plane, and the walls go where the model and plane meet. then it slices the same model with another plane a bit higher in the same way to print the next layer and so on. a conical slicer does the same thing, but intersects the 3d model with a conical surface, not a plane. There are cam systems which really understand the boundaries of the tool, cutting head, and machine. [1] the best ones can work in very constrained situations. it's expensive software, because it has to actually work right to avoid expensive damage. there's a whole frontier here, to build 3d printing systems that have more intelligent path.

Conical Slicing A Different Angle Of 3d Printing Cnc Kitchen A normal slicer intersects the 3d model to be printed with a 2d plane, and the walls go where the model and plane meet. then it slices the same model with another plane a bit higher in the same way to print the next layer and so on. a conical slicer does the same thing, but intersects the 3d model with a conical surface, not a plane. There are cam systems which really understand the boundaries of the tool, cutting head, and machine. [1] the best ones can work in very constrained situations. it's expensive software, because it has to actually work right to avoid expensive damage. there's a whole frontier here, to build 3d printing systems that have more intelligent path. This is easy to implement mathematically and works reasonably well, except when you have overhangs of more than about 60 degrees on most printers. the idea of slicing in a cone rather than a plane. This is managed on the printer side (marlin) rather than on the slicer side). so the hardware is ready to accept this 3d contiunous motion. i do not have much use for this slicing mode yet but i am sure we could come up with some cool things to print soon with the limitation of printing head nozzle clearance angles he is showing.

.png)

Conical Slicing A Different Angle Of 3d Printing Cnc Kitchen This is easy to implement mathematically and works reasonably well, except when you have overhangs of more than about 60 degrees on most printers. the idea of slicing in a cone rather than a plane. This is managed on the printer side (marlin) rather than on the slicer side). so the hardware is ready to accept this 3d contiunous motion. i do not have much use for this slicing mode yet but i am sure we could come up with some cool things to print soon with the limitation of printing head nozzle clearance angles he is showing.

Conical Slicing A Different Angle Of 3d Printing Cnc Kitchen

Conical Slicing A Different Angle Of 3d Printing Cnc Kitchen

Comments are closed.