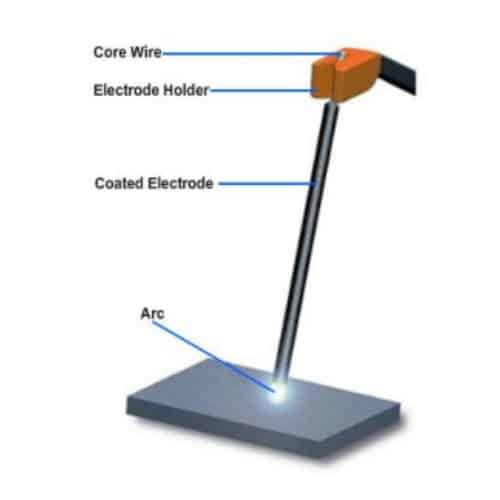

Consumable Electrode Welding

Different Types Of Welding Rods And Their Uses Right Stick Electrodes The two main types of welding electrodes are consumable and non consumable electrodes. when welding two pieces of metal, the electrode helps conduct electricity from the workpiece to fuse two metal pieces. consumable electrodes are melted and reduced in size during the welding process. meanwhile, non consumable electrodes are more durable and. A consumable electrode itself melts down during welding and subsequently deposits on the weld bead. a non consumable electrode does not melt down or deposit on the weld bead. it remains intact throughout the welding. a consumable electrode acts as filler and thus it supplies necessary filler material intended to fill the root gap.

.jpg)

Mechanical Technology Inert Gas Consumable Electrode Process Mig Welding Non consumable electrodes are commonly used in tig welding (where a tungsten electrode is used to produce the arc). 2. material type – consumable electrodes are often preferred for applications where high deposition rates and efficient material transfer are essential. Introduction. shielded metal arc welding (smaw), commonly known as stick welding, is a pivotal manual arc welding process. it employs a consumable electrode enveloped in a flux to fuse metals together. renowned for its versatility and simplicity, smaw has earned its place as one of the most widely used welding techniques globally. Electrode welding works off of this constant current (cc) by short circuiting between a flux covered electrode held in the stinger and the workpiece. this creates an electrical arc that generates heat to melt the workpiece and the electrode simultaneously. the electrode melts to deposit filler metal into the weld pool (the puddle of molten. In carbon or tungsten (tig) welding there are no molten droplets to be forced across the gap and onto the work. filler metal is melted into the joint from a separate rod or wire. more of the heat developed by the arc is transferred to the weld pool with consumable electrodes. this produces higher thermal efficiencies and narrower heat affected.

Types Of Welding Electrodes Complete Guide Electrode welding works off of this constant current (cc) by short circuiting between a flux covered electrode held in the stinger and the workpiece. this creates an electrical arc that generates heat to melt the workpiece and the electrode simultaneously. the electrode melts to deposit filler metal into the weld pool (the puddle of molten. In carbon or tungsten (tig) welding there are no molten droplets to be forced across the gap and onto the work. filler metal is melted into the joint from a separate rod or wire. more of the heat developed by the arc is transferred to the weld pool with consumable electrodes. this produces higher thermal efficiencies and narrower heat affected. Generally, consumable electrodes are widely utilized in metal inert gas (mig) or shield metal arc (smaw) welding, contain lower melting points, and are made out of steel with filler material. the lower melting point designates the weightiest difference—these electrodes fully melt away as the welder works, becoming the structured weld fusion. Tig welding. plasma welding. consumable (fusible) electrode type. shielded metal arc welding. mag welding. mig welding. electrogas arc welding (egw) the classifications above are just an example. there are various ways to classify the types, and some may differ from the table above.

Mig Welding Electrode Wire Amcoweld Inc Pte Ltd Generally, consumable electrodes are widely utilized in metal inert gas (mig) or shield metal arc (smaw) welding, contain lower melting points, and are made out of steel with filler material. the lower melting point designates the weightiest difference—these electrodes fully melt away as the welder works, becoming the structured weld fusion. Tig welding. plasma welding. consumable (fusible) electrode type. shielded metal arc welding. mag welding. mig welding. electrogas arc welding (egw) the classifications above are just an example. there are various ways to classify the types, and some may differ from the table above.

Manual Arc Welding With Consumable Electrode With A Coating Stock Image

Differences Between Consumable And Non Consumable Electrode Youtube

Comments are closed.