Continuous Cooling Transformation Diagram 1045

Calculated Continuous Cooling Transformation Diagram For The Aisi 1045 Definition: stability of phases during continuous cooling of austenite. there are two types of cct diagrams. i) plot of (for each type of transformation) transformation start, specific fraction of transformation and transformation finish temperature against transformation time on each cooling curve. Calculated continuous cooling transformation diagram for the aisi 1045 steel. the three curves correspond to the minimum cooling rate needed to avoid pearlite formation (10°c s), the maximum rate.

Calculated Continuous Cooling Transformation Diagram For The Aisi 1045 Aisi sae designation: aisi 1045 jis designation: jis s 45c chemical composition in weight %: 0.43 0.50% c, 0.60 0.90% mn, max. 0.04% p, max. 0.05% s steel group: carbon steels note: continuous cooling transformation diagram of an unalloyed steel containing 0.45% c. austenitization temperature, 880 c (1620 f). reference: not shown in this demo. The continuous cooling transformation (cct) diagram shown on figure 1, is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. used to indicate when transformations occur as the initially austenitized material is continuously cooled at a specific rate; in addition, the final microstructure and mechanical. What you really need is to obtain a cct (continuous cooling transformation) diagram of aisi type 1045. most of the cct diagrams contain various cooling rate curves in deg f (c) sec with a hardness and or even phase transformations superimposed at the bottom of the time axis corresponding to a particular cooling rate curve. There are two types of continuous cooling diagrams drawn for practical purposes. type 1: this is the plot beginning with the transformation start point, cooling with a specific transformation fraction and ending with a transformation finish temperature for all products against transformation time for each cooling curve. type 2: this is the plot.

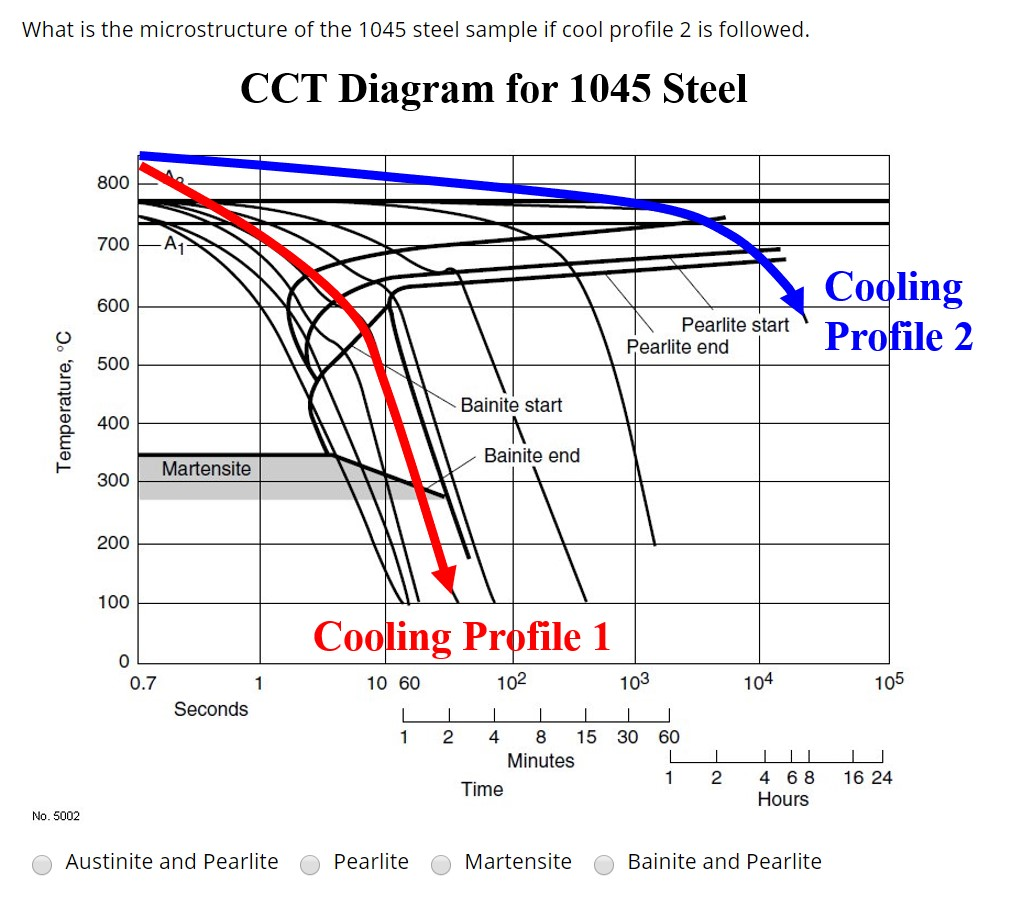

Solved What Is The Microstructure Of The 1045 Steel Sample Chegg What you really need is to obtain a cct (continuous cooling transformation) diagram of aisi type 1045. most of the cct diagrams contain various cooling rate curves in deg f (c) sec with a hardness and or even phase transformations superimposed at the bottom of the time axis corresponding to a particular cooling rate curve. There are two types of continuous cooling diagrams drawn for practical purposes. type 1: this is the plot beginning with the transformation start point, cooling with a specific transformation fraction and ending with a transformation finish temperature for all products against transformation time for each cooling curve. type 2: this is the plot. The 1045 steel is extensively heat treated because its mechanical properties can be easily improved by thermal processes. reliable knowledge of the relationship between microscopic structure and. In the present study the austenite decomposition kinetics for a 1045 steel was modeled using a modification of the transformation equation proposed by li et al. [1]. the kinetics of the continuous cooling transformation were determined directly from an isothermal transformation diagram.

Calculated Continuous Cooling Transformation Diagram For The Aisi 1045 The 1045 steel is extensively heat treated because its mechanical properties can be easily improved by thermal processes. reliable knowledge of the relationship between microscopic structure and. In the present study the austenite decomposition kinetics for a 1045 steel was modeled using a modification of the transformation equation proposed by li et al. [1]. the kinetics of the continuous cooling transformation were determined directly from an isothermal transformation diagram.

Calculated Continuous Cooling Transformation Diagram For The Aisi 1045

Comments are closed.