Continuous Cooling Transformation Diagram Aisi 4140

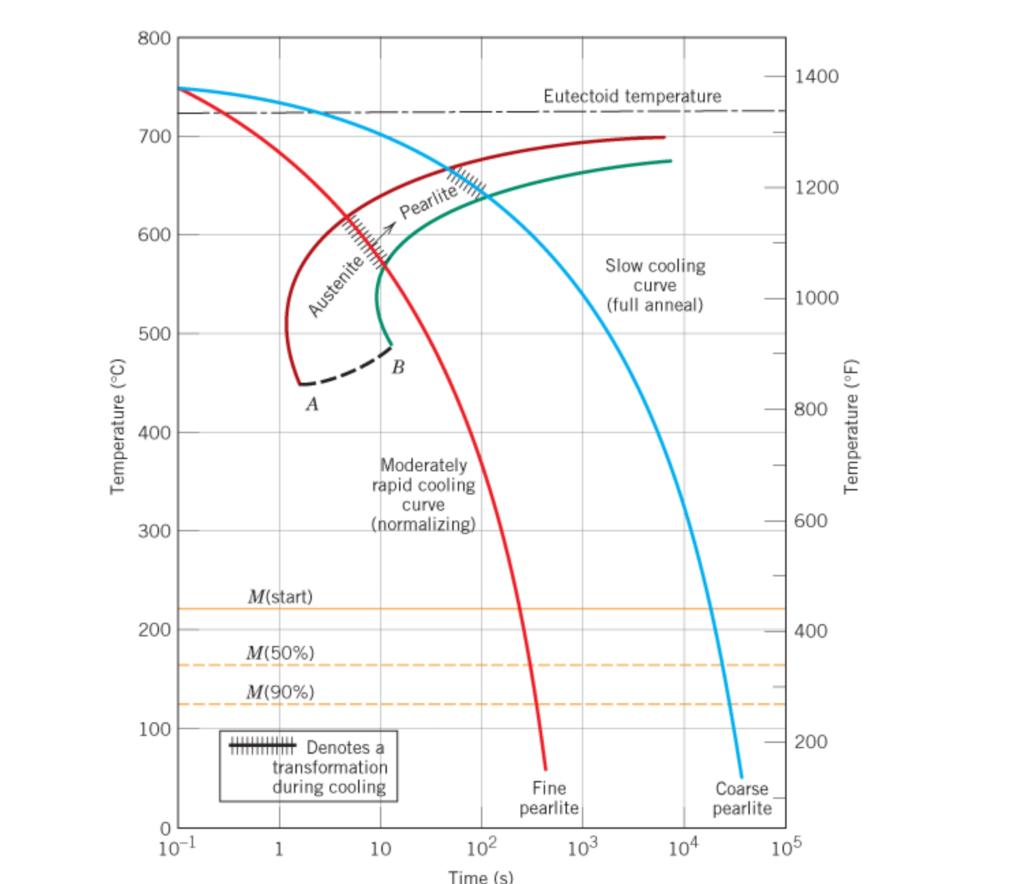

Continuous Cooling Transformation Diagram Definition: stability of phases during continuous cooling of austenite. there are two types of cct diagrams. i) plot of (for each type of transformation) transformation start, specific fraction of transformation and transformation finish temperature against transformation time on each cooling curve. 1.4 ttt diagram for 4140 steel we can gain some quantitative insight as to what happens in 4140 steel under a general thermal cooling history from a temperature in the austenite (a) regime by examining its isothermal time temperature transformation (ttt) curve, as shown in fig. 2. the.

Schematic Illustration Of Continuous Cooling Transformation Cct Continuous cooling transformation (cct) diagrams are widely used when heat treating steels and represent which type of phase will occur in a material as it is cooled at different cooling rates. cct diagrams are constructed on the basis of dilatometry measurements on relatively small testing samples (cylindrical shape with diameter of 4mm and length of 11 mm in this study). the main aim of this. Typical continuous cooling transformation diagrams using this method are shown in [1]. these diagrams allow the prediction of hardness and microstructure in the center of any diameter bar. this is also the most common method for displaying cct diagrams. figure 1: cct diagram for aisi 1060 steel. figure 2: cct diagram for aisi 5160 steel. According to grossmann's eq 7, the ideal critical diameter for 47gt steel, using the steel composition shown in fig. 7 were made from modified aisi 1040 steel, aisi 4340 steel, and 47gt steel. There are two main types of transformation diagram that are helpful in selecting the optimum steel and processing route to achieve a given set of properties. these are time temperature transformation (ttt) and continuous cooling transformation (cct) diagrams. cct diagrams are generally more appropriate for engineering applications as components.

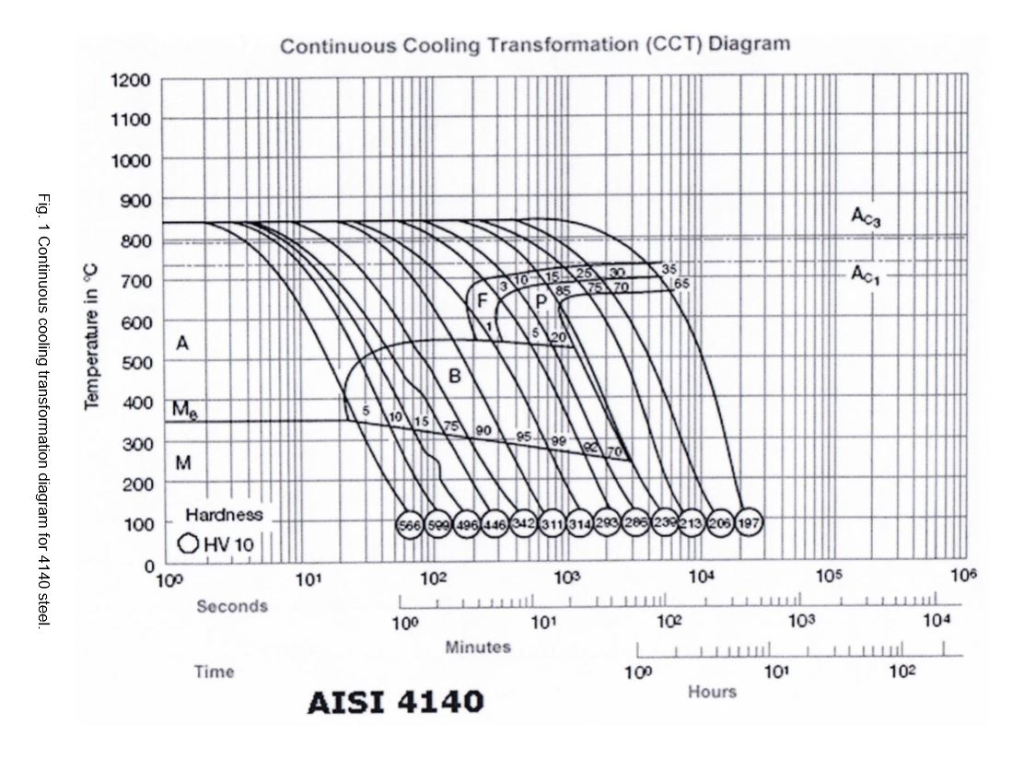

Explain Using Cct Curves Which Microstructures Chegg According to grossmann's eq 7, the ideal critical diameter for 47gt steel, using the steel composition shown in fig. 7 were made from modified aisi 1040 steel, aisi 4340 steel, and 47gt steel. There are two main types of transformation diagram that are helpful in selecting the optimum steel and processing route to achieve a given set of properties. these are time temperature transformation (ttt) and continuous cooling transformation (cct) diagrams. cct diagrams are generally more appropriate for engineering applications as components. Time temperature transformation diagram for 4140 steel taken from [23], [51] with permission. download: download high res image (176kb) download: download full size image; fig. a.24. continuous cooling transformation diagram for 4140 steel indicating the percentages of each phase formed at a variety of cooling rates taken from [21], [55] with. This atlas is a collection of continuous cooling transformation diagrams applicable to low carbon low alloy weld metals. it will be of assistance to welding engineers, welding metallurgists, welding consumables designers in industry. table of contents.

Temperature Cooling Rate Time Curves For 4140 Steel Quenched In Time temperature transformation diagram for 4140 steel taken from [23], [51] with permission. download: download high res image (176kb) download: download full size image; fig. a.24. continuous cooling transformation diagram for 4140 steel indicating the percentages of each phase formed at a variety of cooling rates taken from [21], [55] with. This atlas is a collection of continuous cooling transformation diagrams applicable to low carbon low alloy weld metals. it will be of assistance to welding engineers, welding metallurgists, welding consumables designers in industry. table of contents.

Comments are closed.