Cooling Compressor Diagram

Atlas Copco Air Compressor Schematic Diagram Wiring Diagram Because the compressed air temperature out of the compressor is 10°c higher than the ambient tempera ture, the refrigerant dryer inlet temperature will be maximum 30 10 = 40°c. in addition, the desired pressure dew point is 5°c. the appropriate correction factor 0.95 is obtained from the atlas copco data sheet. The refrigerant leaves the evaporator, travels down the suction line, and heads back to the compressor, where the cycle starts all over again. refrigerant lines. suction line = line between the evaporator and the compressor. the suction line should contain low pressure superheated suction vapor.

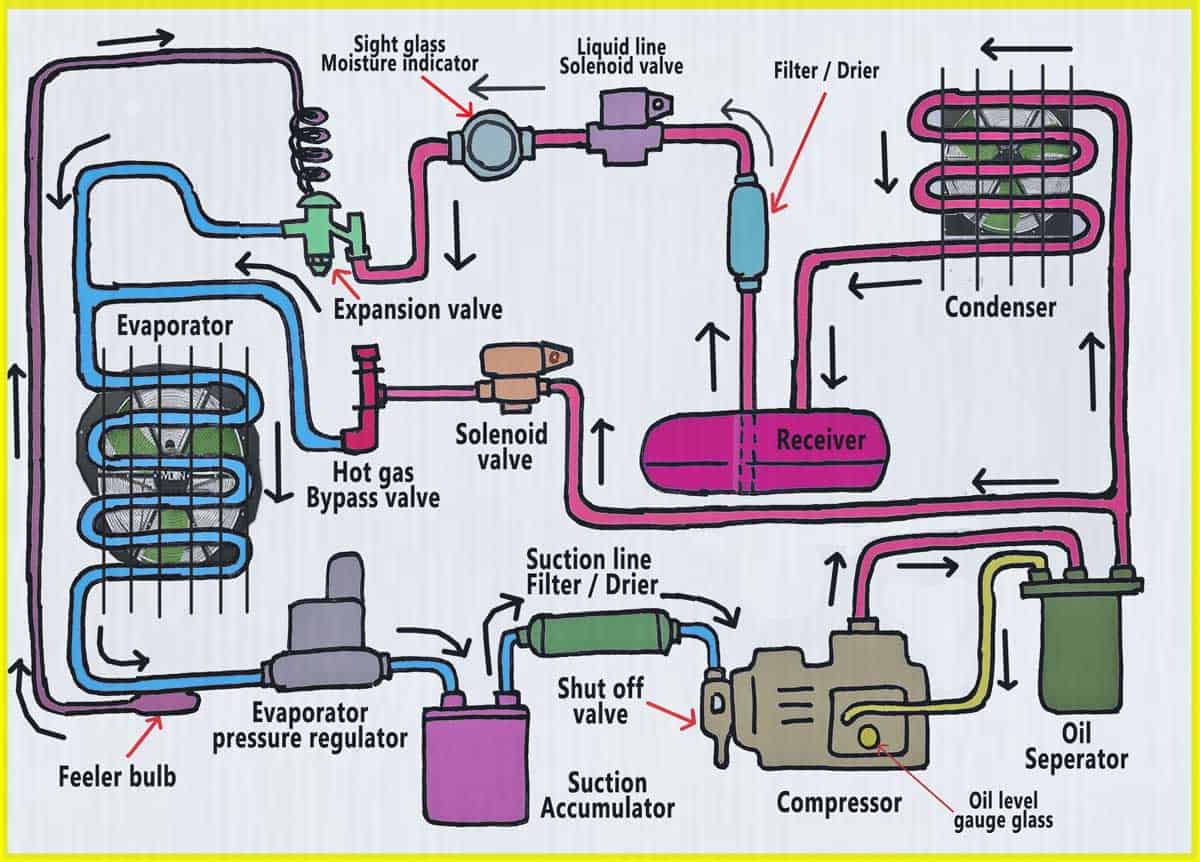

Cooling System What Is The Main Purpose Of The Compressor Refrigeration cycle diagram: how it works and what you need to know: a basic refrigeration cycle consists of 4 major components: compressor, condenser, thermostatic expansion valve (tev), and evaporator. these components allow the heat to transfer from one location to another, creating a cooling effect in the desired area. Demand cooling is designed to work on all copeland discus compressors equipped with injection ports. a different kit is required for each compressor body style and control voltage. see table 2 for a listing of demand cooling kit part numbers. the system must be clean. Goal. we want to design a vapor compression refrigeration cycle to absorb heat from a cool environment and reject it to a warm environment. the design is to be based upon the ideal vapor compression refrigeration cycle, with four components: a cooler (where we reject the heat), a throttle, a heater (where we absorb the heat), and a compressor. Basic & definition. the refrigeration cycle is a thermodynamic cycle that generates refrigerating effects with the use of mainly an evaporator, compressor, condenser & expansion valve. this process is basically a thermodynamic process where the working fluid absorbs the heat from the surrounding at a low temperature and reject the heat to the.

Air Compressor Cooling System With Hru The Layout Shows The Cooling Goal. we want to design a vapor compression refrigeration cycle to absorb heat from a cool environment and reject it to a warm environment. the design is to be based upon the ideal vapor compression refrigeration cycle, with four components: a cooler (where we reject the heat), a throttle, a heater (where we absorb the heat), and a compressor. Basic & definition. the refrigeration cycle is a thermodynamic cycle that generates refrigerating effects with the use of mainly an evaporator, compressor, condenser & expansion valve. this process is basically a thermodynamic process where the working fluid absorbs the heat from the surrounding at a low temperature and reject the heat to the. In its simplest form, the refrigeration cycle consists of just 4 basic components to complete the circuit: a compressor. a condenser. a restriction. an evaporator. that’s it. well, that’s almost it – we also need a refrigerant to cycle inside the circuit. as the name suggests, the refrigeration process is a cycle. This is because cooling water removes approximately 90% of the heat energy created by the electric motor. to be effective, water cooled compressors use one of three main principles: open systems without circulating water (connected to an external water supply). open systems with circulating water (cooling tower).

15 Major Components And Controls Of Refrigeration System Refcon Hvac In its simplest form, the refrigeration cycle consists of just 4 basic components to complete the circuit: a compressor. a condenser. a restriction. an evaporator. that’s it. well, that’s almost it – we also need a refrigerant to cycle inside the circuit. as the name suggests, the refrigeration process is a cycle. This is because cooling water removes approximately 90% of the heat energy created by the electric motor. to be effective, water cooled compressors use one of three main principles: open systems without circulating water (connected to an external water supply). open systems with circulating water (cooling tower).

Comments are closed.