Cooling Tower Bypass Diagram

Cooling Tower Bypass Line The Engineering Mindset When designing a cooling tower system for free cooling applications, several piping details should be considered to ensure proper winter operation of the unit. a cooling tower bypass needs to be incorporated into the system design to allow water to “bypass” the tower’s water distribution system as a means of capacity. Design capacity – 430.0 gpm design head – 47.0 feet motor size – 10 hp. less than anticipated pump headthe pump point shift has increased flow. over design to the order of 45%. cavitational and or tower vortex can occur unless. corrective measures are applied.the pump impeller diameter could, and should be cut down.

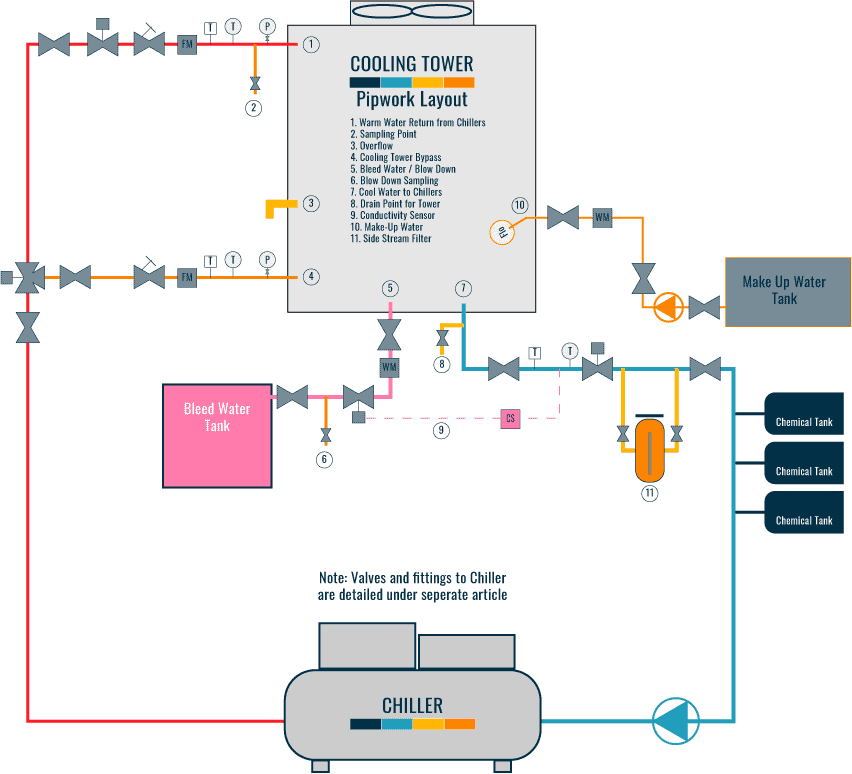

Cooling Tower Piping Layout And Diagrams Constructandcommission Cooling tower bypass pipework [3] a cooling tower bypass is used mainly in colder climates, where there is risk that the supply water temperature to the condenser side of the chillers is not at the required temperature set point, i.e its to cold system. Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. Yes, a bypass is required for any chilled water evaporator, hot water condenser (heating load) and source water side (geothermal, cooling tower or closed circuit cooler) with variable pumping. the bypass must be piped in such a way that the temperature and differential pressure sensors are still sensing active flow. Cooling tower bypass line there might also be a bypass line with a motorised valve across the cooling towers flow and return. this can have various functions such as maintaining minimum flow rate and also protecting the chiller from tripping on low and high pressure due to the temperature of the return condenser water being out of design limits.

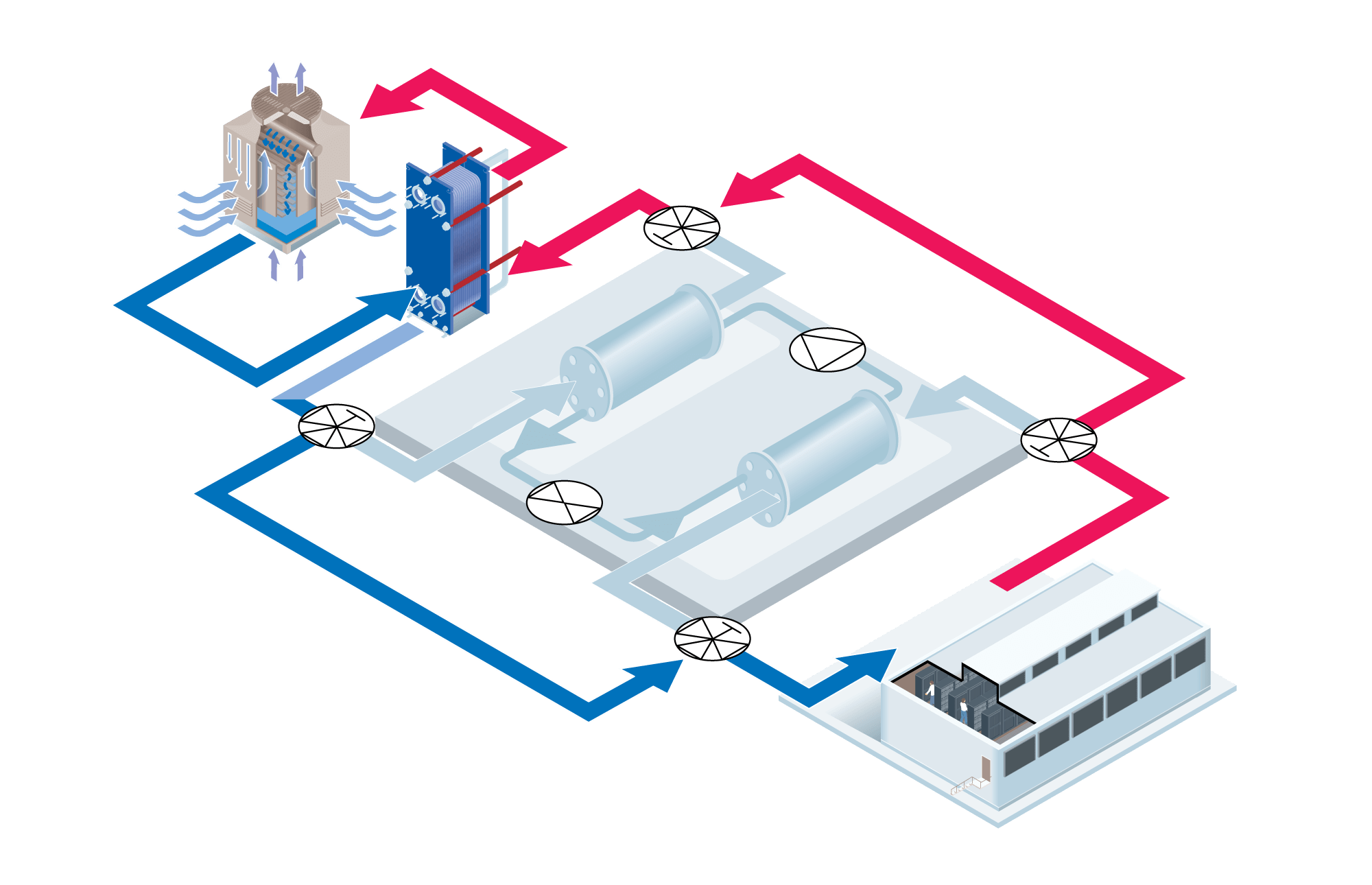

Isolation Of Chillers And Bypass In Closed Cooling Tower Yes, a bypass is required for any chilled water evaporator, hot water condenser (heating load) and source water side (geothermal, cooling tower or closed circuit cooler) with variable pumping. the bypass must be piped in such a way that the temperature and differential pressure sensors are still sensing active flow. Cooling tower bypass line there might also be a bypass line with a motorised valve across the cooling towers flow and return. this can have various functions such as maintaining minimum flow rate and also protecting the chiller from tripping on low and high pressure due to the temperature of the return condenser water being out of design limits. Understanding the basics of piping and controls is step number one in the cooling tower industry. but how effectively a cooling tower piping system is designed and installed can have a critical impact on system efficiency, functionality and even safety. properly engineered condenser, chiller and cooling tower piping and controls will improve heat transfer and avoid problems such as air. Depending on cooling requirements, one, two, or three chillers are in operation. manual open close butterfly valves isolate the pumps, chillers, cooling towers, and strainers during commissioning or maintenance. the 3 way control butterfly valve (diverting valve) performs temperature control on the cooling tower so that the downstream entry.

Cooling Tower Interchanger Alfa Laval Understanding the basics of piping and controls is step number one in the cooling tower industry. but how effectively a cooling tower piping system is designed and installed can have a critical impact on system efficiency, functionality and even safety. properly engineered condenser, chiller and cooling tower piping and controls will improve heat transfer and avoid problems such as air. Depending on cooling requirements, one, two, or three chillers are in operation. manual open close butterfly valves isolate the pumps, chillers, cooling towers, and strainers during commissioning or maintenance. the 3 way control butterfly valve (diverting valve) performs temperature control on the cooling tower so that the downstream entry.

Closed Circuit Cooling Tower Piping Diagrams Circuit Diagram

Cooling Tower Bypass Line The Engineering Mindset

Comments are closed.