Cooling Tower Diagram Water

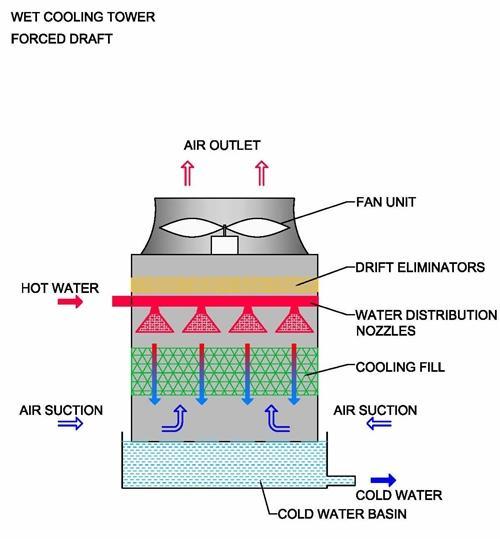

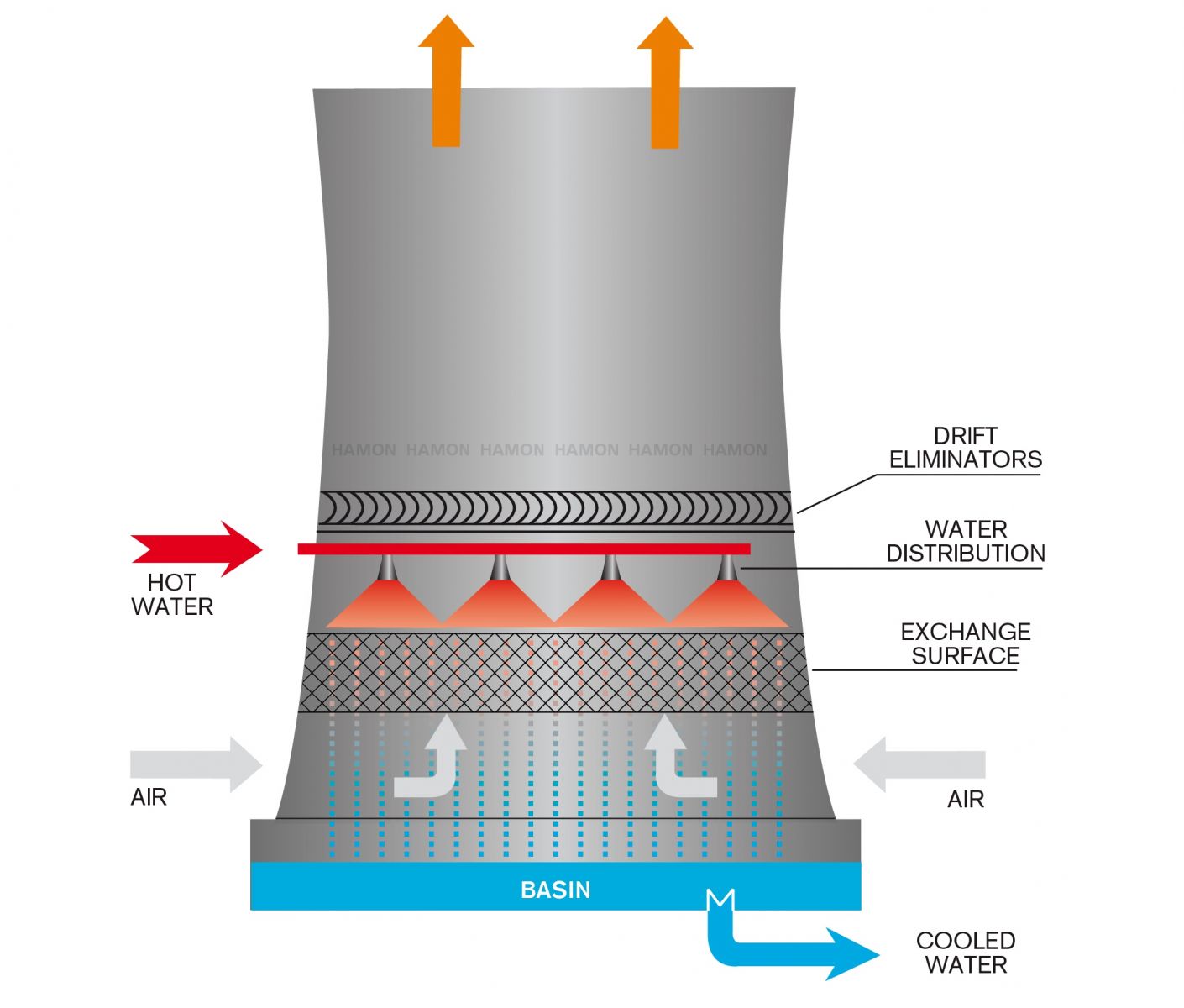

Cooling Tower Diagram A Go To Guide To Learn About Their Function Flow of air and condenser water. just to recap. warm condenser water enters the tower and is sprayed over the fill packaging. this spray runs down the fill packaging creating a thin film of water over it, the water will evaporate and cool down. cool dry air enters through the bottom of the tower and passes through the fill packaging in the. In a cross flow cooling tower, the hot water basin is used to distribute the warm return water flow uniformly over the tower fill (see figure 6). in a counter flow cooling tower, water sprays are used to distribute the warm water (see figure 8). the fan deck supports the motor and fan of the water spray system.

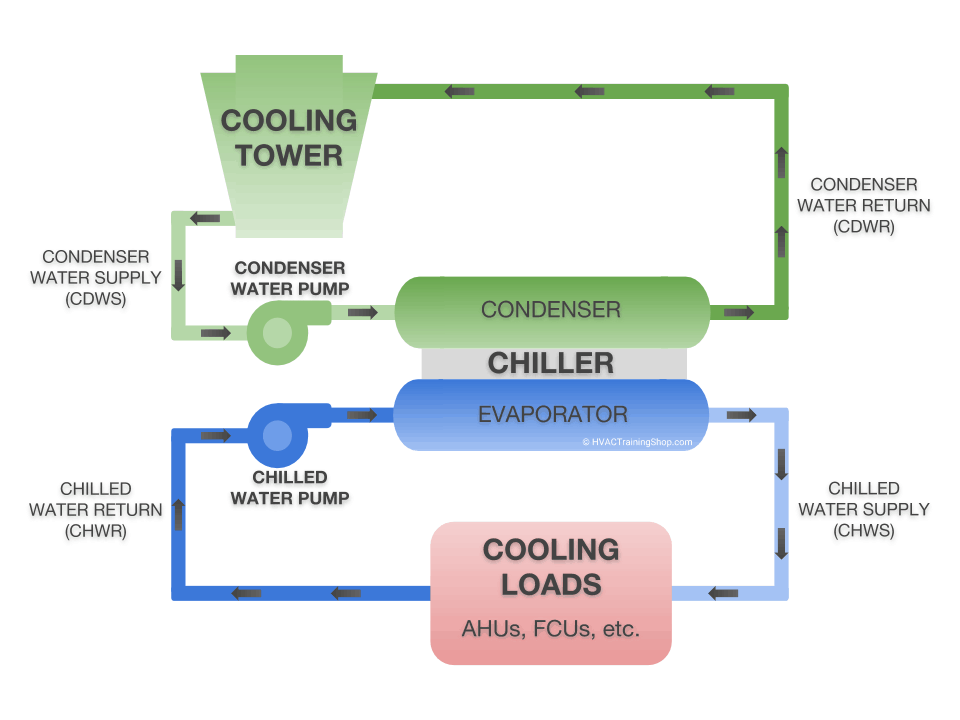

How Cooling Towers Work Diagram Pictures Principles Sara Cooling The water is flashed to air as it passes throughout the cooling tower. the air has been pulled using a motor driven electrical "cooling tower fan". when the air and water come into the contact, a little amount of water dissipates, producing a cooling operation. and again the cold water is pumped back to the machine that incorporates heat or the. By fans into the cooling tower and up through the flow of falling water in the cooling tower. drift eliminators are installed to prevent water entrained in the air from leaving the system. 1.3.3 induced draft towers. the term “induced draft” denotes that air is drawn by fans through the flow of falling water and up and out of the cooling tower. Crossflow cooling towers flow diagram in crossflow cooling tower systems the water vertically flows through the fill media while the air horizontally flows across the falling water. that's why they call it "crossflow" because the air and water cross paths or flows. because of the crossing of flows, the air doesn't need to. In the adjacent diagram, water pumped from the tower basin is the cooling water routed through the process coolers and condensers in an industrial facility. the cool water absorbs heat from the hot process streams which need to be cooled or condensed, and the absorbed heat warms the circulating water (c).

What Is A Cooling Tower Cooling Tower Basics Hvac Training Shop Crossflow cooling towers flow diagram in crossflow cooling tower systems the water vertically flows through the fill media while the air horizontally flows across the falling water. that's why they call it "crossflow" because the air and water cross paths or flows. because of the crossing of flows, the air doesn't need to. In the adjacent diagram, water pumped from the tower basin is the cooling water routed through the process coolers and condensers in an industrial facility. the cool water absorbs heat from the hot process streams which need to be cooled or condensed, and the absorbed heat warms the circulating water (c). A cooling tower flow diagram is a visual representation of the flow of water and air in a cooling tower system. it provides a clear understanding of how the cooling tower operates and helps in identifying potential issues or inefficiencies in the system. there are several benefits of using a cooling tower flow diagram. The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser.

Comments are closed.