Cooling Tower Water Treatment вђ Visipraxis

Cooling Tower Water Treatment вђ Visipraxis Due to the mechanism, this type of cooling tower is also called an evaporative cooling tower. this system consists of three main pieces of equipment: the recirculating water pump (s), the heat exchanger (s), and the cooling tower. average temperature change: 10 30° f (6 17° c) amount of water used: moderate. Cooling tower systems are used to remove heat from both manufacturing and utility processes, which can impact both production efficiency and employee working conditions. a thorough understanding and control of the water used in a cooling system is necessary for optimizing its operation. evaporative losses occur during cooling tower operation.

Cooling Tower Water Treatment вђ Visipraxis Scale significantly reduces efficiency by acting as an insulator, preventing effective heat transfer. corrosion control: water, especially when combined with oxygen, can cause corrosion in metal parts of the cooling tower. treatment additives inhibit corrosion to extend the life of the cooling system. microbial control: warm water and nutrients. By fans into the cooling tower and up through the flow of falling water in the cooling tower. drift eliminators are installed to prevent water entrained in the air from leaving the system. 1.3.3 induced draft towers. the term “induced draft” denotes that air is drawn by fans through the flow of falling water and up and out of the cooling tower. Image via pexels. if you use a cooling tower as part of regular operations at your worksite, water treatment is something you need to be aware of. in this handy guide to cooling tower water treatment, we take a look at why this treatment is so necessary in achieving an efficient and safe site, as well as examine the clean water technology and best practices that you can deploy at your own. Scale & deposit control for cooling water systems. fresh water is being added to cooling water towers to replace water lost through leaks or evaporation. but this makeup water contains minerals, dirt, debris and other impurities that build up and insulate the metal surfaces. our forgiving polymers help prevent scale and deposits from forming.

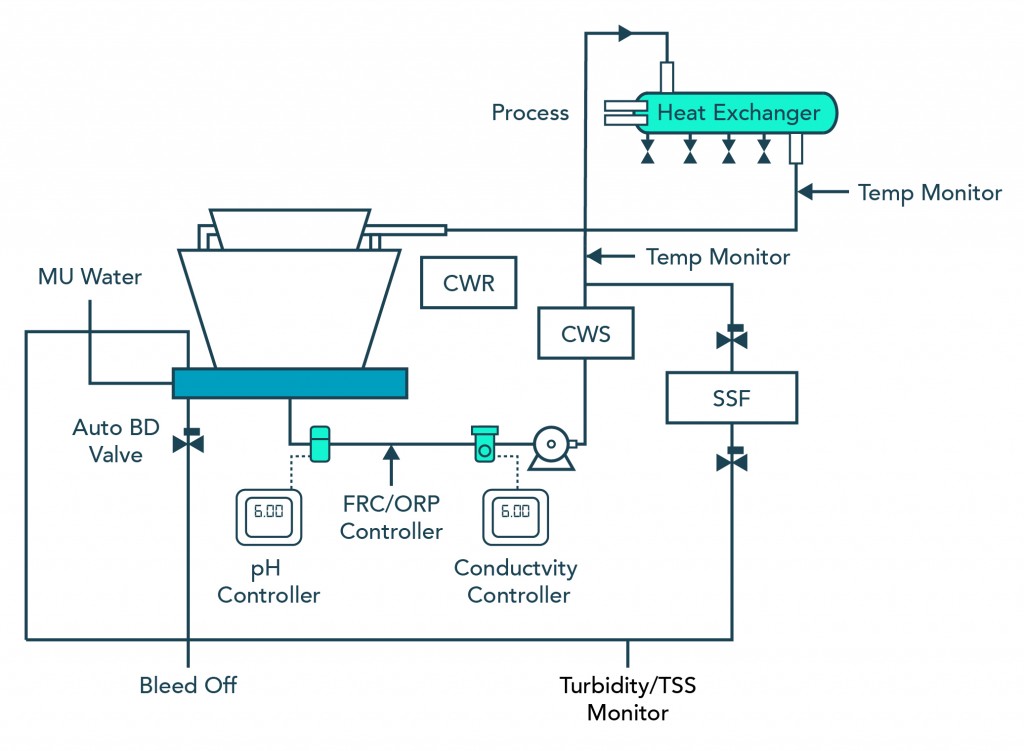

Cooling Tower Water Treatment Veolia Water Technologies Image via pexels. if you use a cooling tower as part of regular operations at your worksite, water treatment is something you need to be aware of. in this handy guide to cooling tower water treatment, we take a look at why this treatment is so necessary in achieving an efficient and safe site, as well as examine the clean water technology and best practices that you can deploy at your own. Scale & deposit control for cooling water systems. fresh water is being added to cooling water towers to replace water lost through leaks or evaporation. but this makeup water contains minerals, dirt, debris and other impurities that build up and insulate the metal surfaces. our forgiving polymers help prevent scale and deposits from forming. Maintaining the ph levels in a cooling tower is crucial for effective water treatment. too high or too low ph can harm equipment and processes in water treatment. operators must regularly check water’s acidity or alkalinity. this ensures optimal performance. balanced ph prevents corrosion and microbial growth. What is in a cooling tower water treatment system? water treatment for cooling towers is made up of an arrangement of multiple types of treatment options that all work together as one larger system. this system’s purpose is to remove damaging particulates from the water that goes into your cooling tower feed, circulation, and blowdown.

Comments are closed.