Cooling Towers Maintenance And Troubleshooting Part 1

Cooling Towers Maintenance Part 1 Youtube Cooling tower maintenance checklist. multiple essential components and steps should be part of your regular cooling tower maintenance checklist. some of the crucial key points that most evaporative cooling towers use to maintain their cooling towers in the best condition are discussed here. structural and mechanical inspection. Create a maintenance schedule based on the manufacturer’s recommendations and your observations. thus, regularly review and update the schedule to ensure timely and proactive maintenance. comprehensive cooling tower maintenance checklist: from daily checks to annual inspections daily. check for any visible leaks, unusual noises, or vibrations.

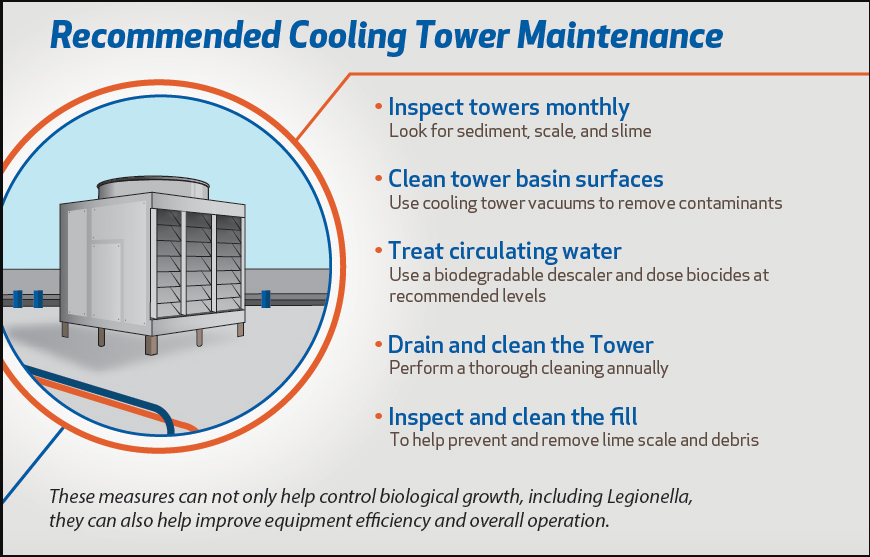

Maintenance Of Cooling Towers 3. top 10 most common cooling tower problems. cooling towers can experience a range of problems that affect their performance and efficiency. here are the ten most common problems: 1. scaling and fouling. scaling and fouling occur when mineral deposits and organic matter accumulate on the fill, basin, and other components of the tower. Cooling towers are essential components of many industrial and commercial setups. they help maintain the optimal temperature of various processes and equipment. however, like any mechanical system, cooling towers can experience issues that need immediate attention. 1. insufficient cooling capacity if your cooling tower is not achieving its desired cooling capacity, it may be due […]. Cooling tower maintenance checklist. regular maintenance is essential to ensure the smooth operation of cooling towers. these critical systems can become less efficient without proper upkeep, leading to increased energy costs and potential breakdowns. check out the checklist below to help you stay on top of your cooling tower maintenance. Regular maintenance revolves around a timely cooling tower inspection. ideally, an inspection of various parts depends on their order of urgency. on a monthly basis, one needs to inspect the general conditions of the cooling tower and the clarity of sump water. under general conditions, you need to start with elements like fan deck, stairway.

Cooling Tower Inspection I Construction And Components With English Cooling tower maintenance checklist. regular maintenance is essential to ensure the smooth operation of cooling towers. these critical systems can become less efficient without proper upkeep, leading to increased energy costs and potential breakdowns. check out the checklist below to help you stay on top of your cooling tower maintenance. Regular maintenance revolves around a timely cooling tower inspection. ideally, an inspection of various parts depends on their order of urgency. on a monthly basis, one needs to inspect the general conditions of the cooling tower and the clarity of sump water. under general conditions, you need to start with elements like fan deck, stairway. Semiannually: lubricate motor bearings and fan shaft bearings in accordance with the cooling tower manufacturer’s recommendation. check the gear reducer oil level with the fan motor off. add oil, as required, to the full mark. check the tightness of all bolts in the fan assembly and mechanical equipment support. These steps will help you create a cooling tower maintenance checklist that suits your facility’s needs. 1. understand cooling tower type. identify and itemize the types of cooling towers your company utilizes. tailor a preventative maintenance checklist to fit each type of cooling tower your organization uses. 2.

Recommended Cooling Tower Maintenance Campbell Mechanical Services Semiannually: lubricate motor bearings and fan shaft bearings in accordance with the cooling tower manufacturer’s recommendation. check the gear reducer oil level with the fan motor off. add oil, as required, to the full mark. check the tightness of all bolts in the fan assembly and mechanical equipment support. These steps will help you create a cooling tower maintenance checklist that suits your facility’s needs. 1. understand cooling tower type. identify and itemize the types of cooling towers your company utilizes. tailor a preventative maintenance checklist to fit each type of cooling tower your organization uses. 2.

Evapco Cooling Tower Maintenance Manual

How To Troubleshoot Your Cooling Towers Maintenance And Repair

Comments are closed.