Corrugated Box Production Process An In Depth Overview Corrugated

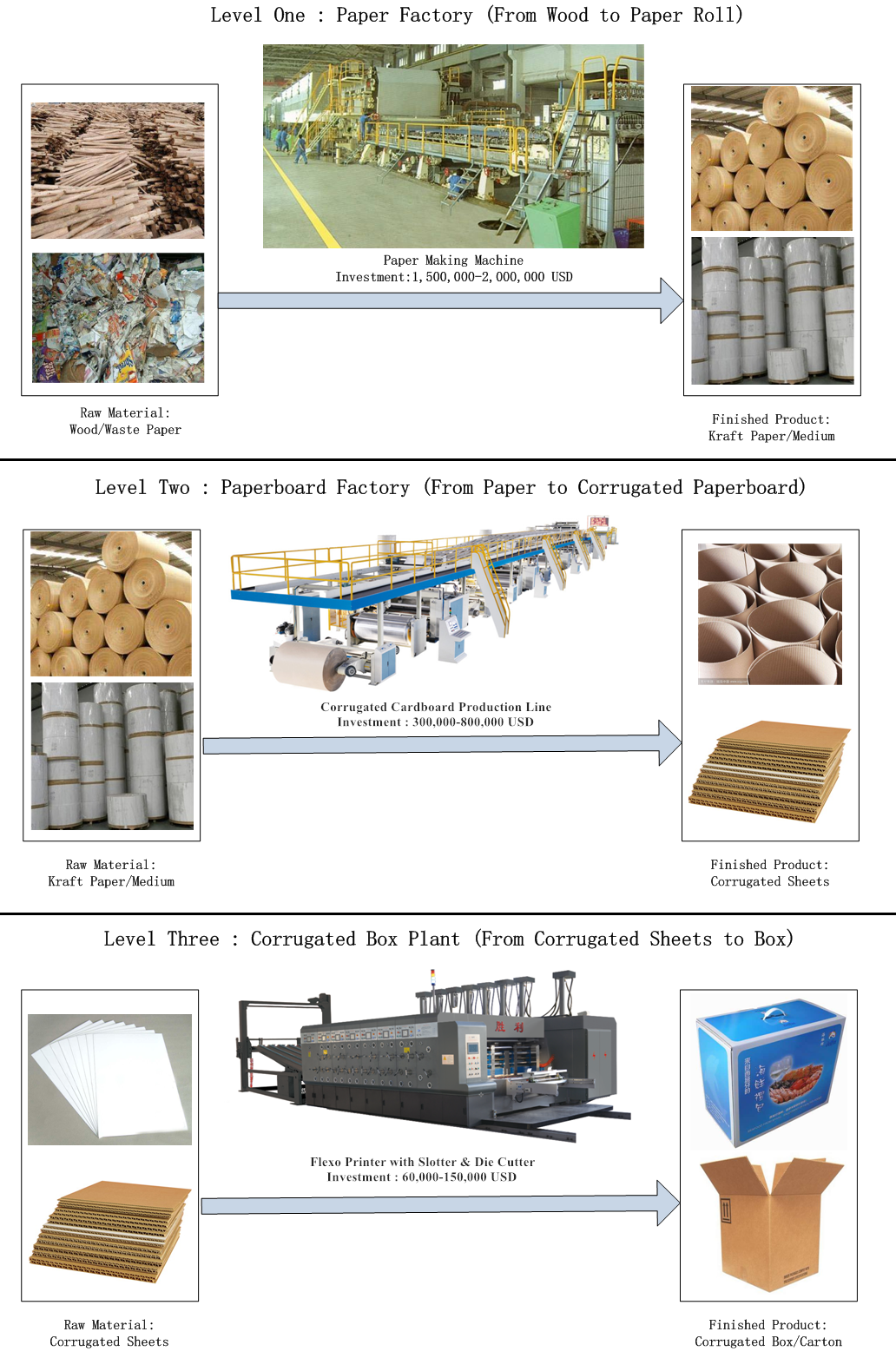

Corrugated Carton Machine Corrugated Cardboard Production Line A corrugated box, commonly known as a cardboard box, is a versatile packaging solution widely used for shipping, storage, and retail purposes. it is constructed from layers of paperboard, typically consisting of three main components: an inner liner, an outer liner, and a corrugated medium sandwiched between them. The combined board product coming off of the dry end of the corrugator at a full line plant is work in process (wip). it will move on to the converting stations within the plant. the product coming off of a sheet feeder’s corrugator is considered finished goods for that plant. it will not be converted into boxes on the premises.

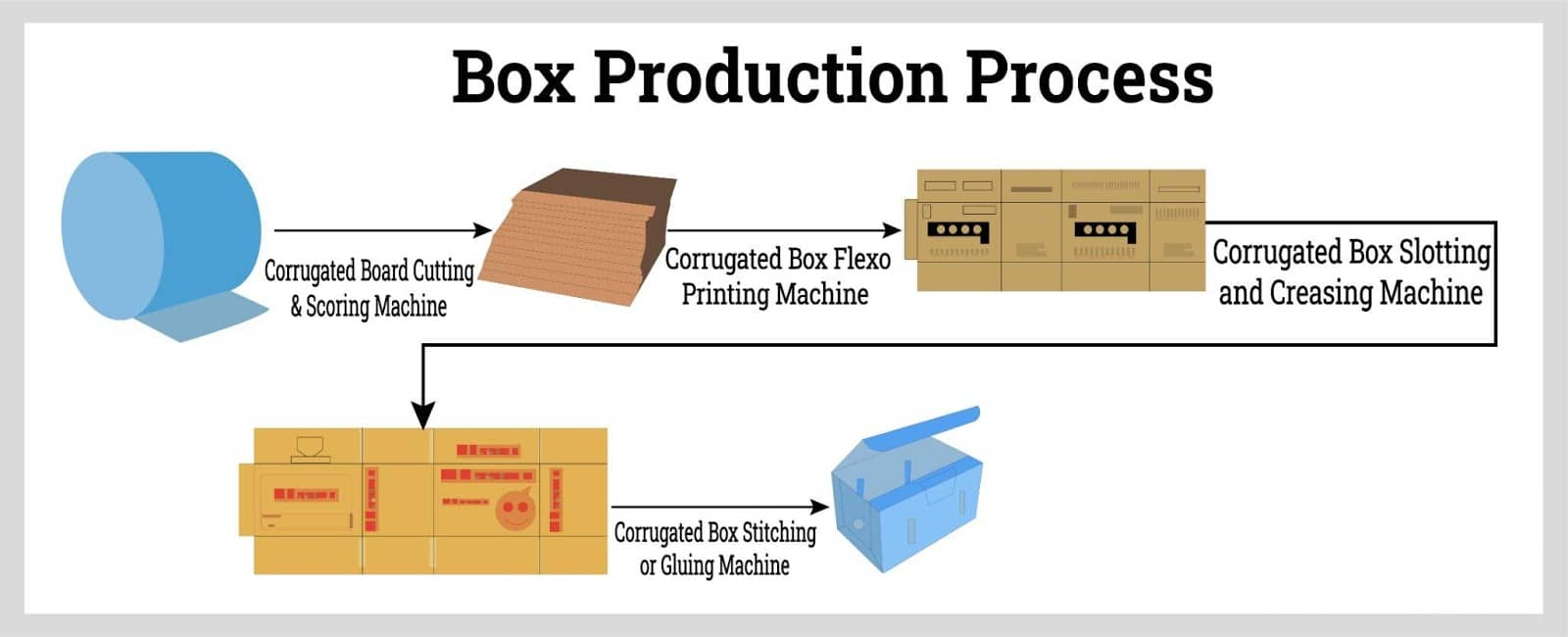

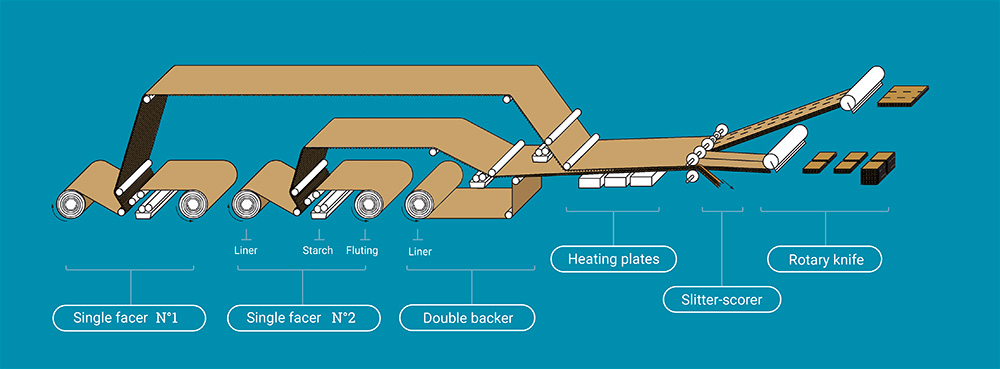

Corrugated Box Production Process An In Depth Overview Corrugated The wet section of the corrugated box manufacturing process involves the initial stages of creating corrugated raw paper. this section includes various equipment that facilitates the formation of corrugated cardboard. one of the main pieces of equipment in the wet section is the single sided corrugator. this machine combines different layers of. The corrugator. a corrugator is a set of machines designed to bring together three, five or seven sheets of paper to form single, double or triple wall board in a continuous process. the 3 key stages: corrugating the flutes and gluing to a single liner. gluing the outside liner to make a rigid board. cutting the board to the desired size. To make corrugated boxes, you need three main materials: paper, steam, and adhesive. the process begins with paper. paper is used to make the two main components of corrugated fiberboard: the linerboard—used as the outer facings. the medium—fluted paper that is attached to the linerboard to produce combined board in a continuous web. Ever wondered how corrugated boxes are made? this step by step process shows how they are manufactured and produced by georgia pacific, a leading box manufac.

Corrugated Paper Process At Larry Reid Blog To make corrugated boxes, you need three main materials: paper, steam, and adhesive. the process begins with paper. paper is used to make the two main components of corrugated fiberboard: the linerboard—used as the outer facings. the medium—fluted paper that is attached to the linerboard to produce combined board in a continuous web. Ever wondered how corrugated boxes are made? this step by step process shows how they are manufactured and produced by georgia pacific, a leading box manufac. Corrugated boxes can be manufactured easily with the few steps that are listed below. first, let's start with the cardboard paperboard that will eventually be made into the box and liner: the cardboard is chopped into very thin sheets and then send through a machine that mixes many layers together. this process produces one thick piece of. Linerboards: linerboards form the inner and outer facings of corrugated fiber boxes and are chosen for their structural and or decorative properties. they can be made from white or brown, kraft or recycled fibers, or a blend of both. pasting: two, three, or four plies of paper and paperboard are glued together.

The Production Of Modern Corrugated Packaging Fefco Corrugated boxes can be manufactured easily with the few steps that are listed below. first, let's start with the cardboard paperboard that will eventually be made into the box and liner: the cardboard is chopped into very thin sheets and then send through a machine that mixes many layers together. this process produces one thick piece of. Linerboards: linerboards form the inner and outer facings of corrugated fiber boxes and are chosen for their structural and or decorative properties. they can be made from white or brown, kraft or recycled fibers, or a blend of both. pasting: two, three, or four plies of paper and paperboard are glued together.

Comments are closed.