Difference Between Closed And Open Circuit Cooling Towers Tsur Ben David

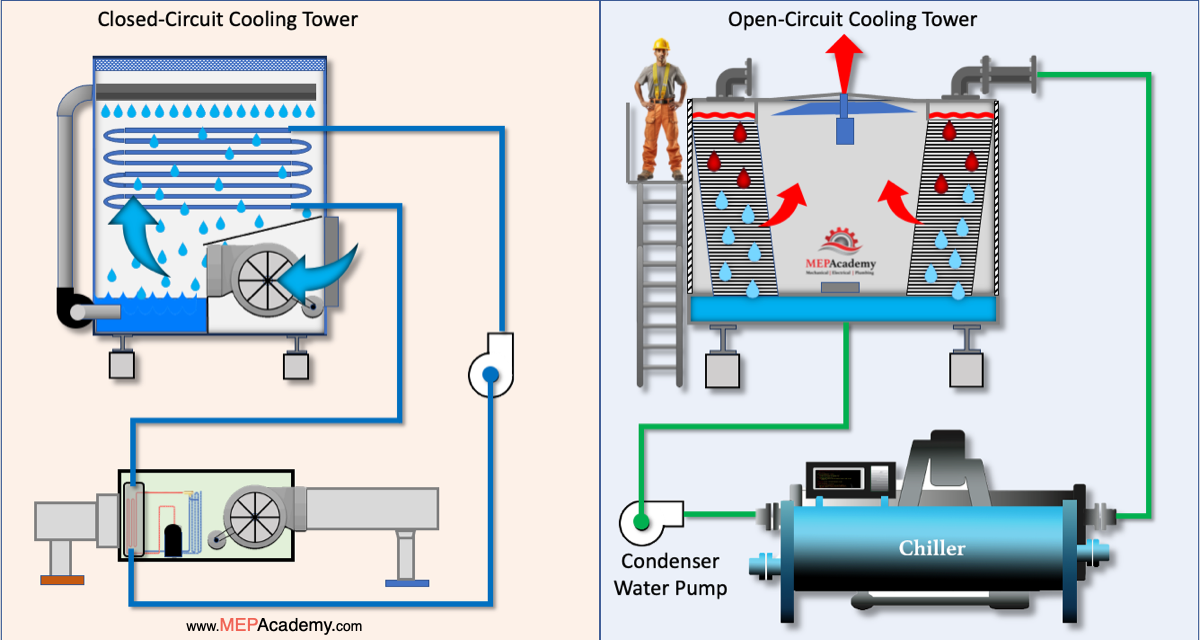

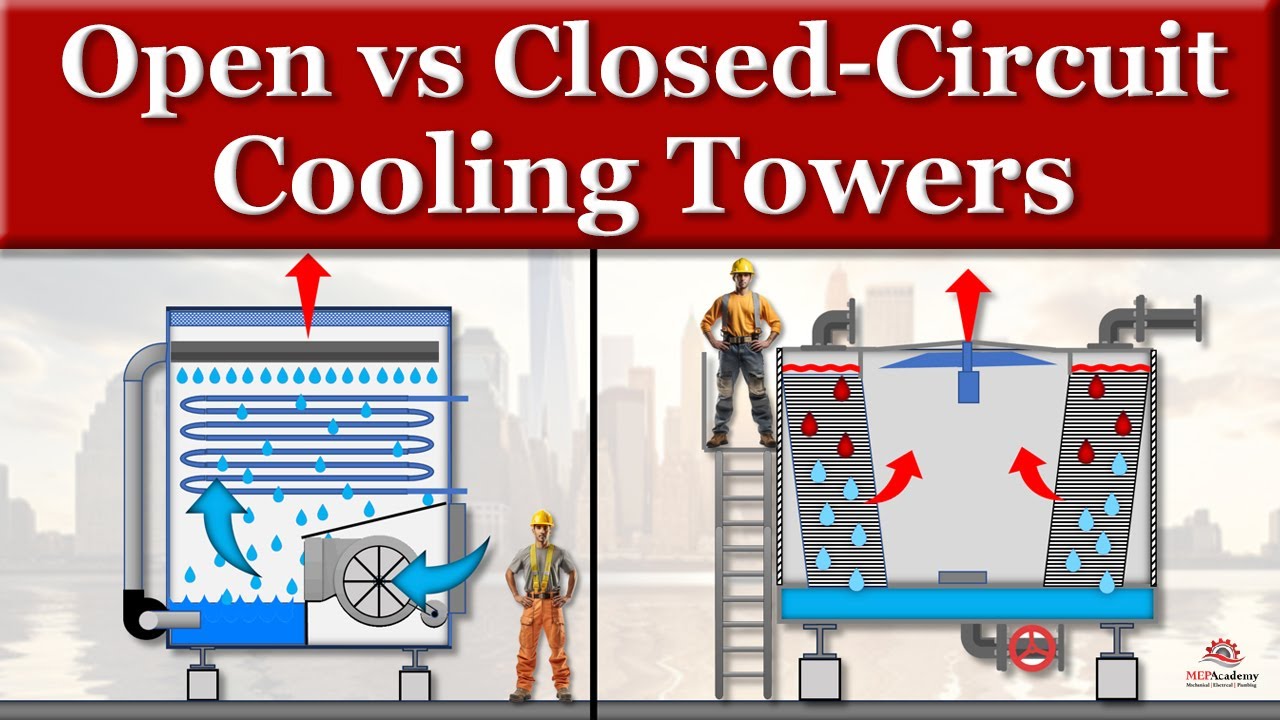

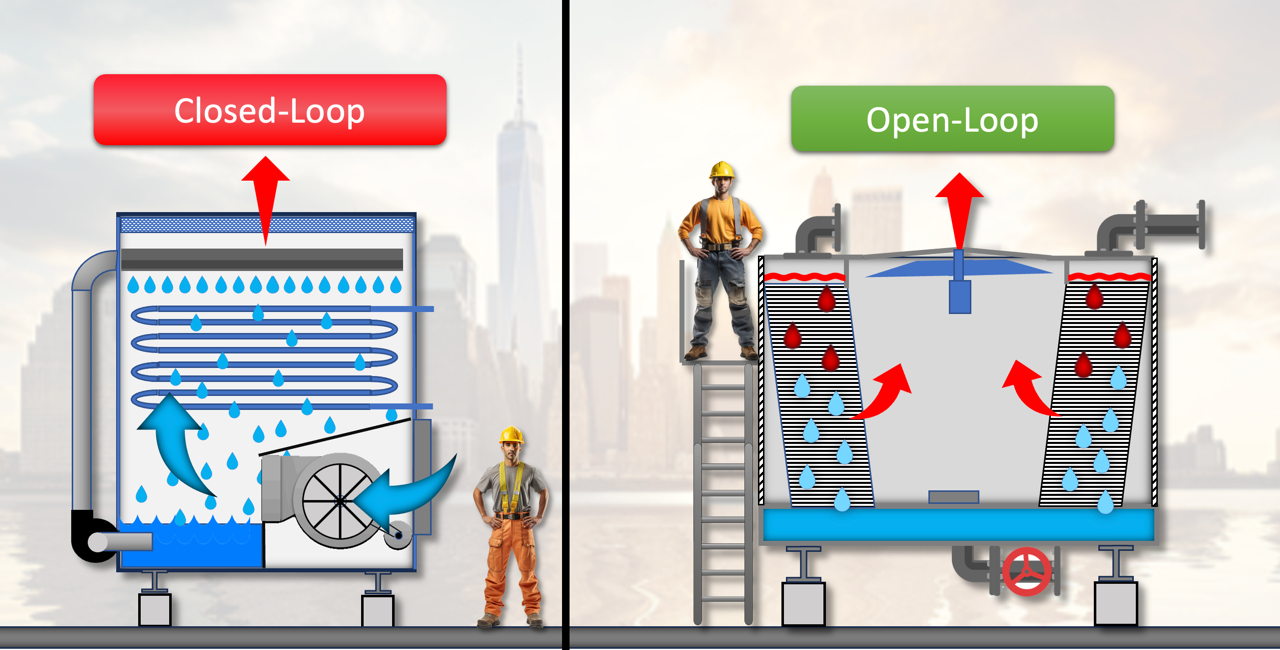

Closed Circuit Vs Open Circuit Cooling Towers Mep Academy A cooling tower used to cool down and circulate water that is used in different settings like chemical plants, oil refineries, thermal power stations, petroc. More about closed circuit cooling towers. a closed circuit cooling tower, or dry cooling tower, involves no contact between the air and the fluid being cooled. this tower has two separate fluid circuits, one in which the fluid is recirculated on the outside of the second circuit, which is a bundle of tubes through which the hot water is flowing.

How To Pick A Cooling Tower Comparing Open And Closed Loop Towers Closed loop vs open loop operation. in a closed circuit cooling tower, the process fluid, which could be water, or a water glycol mixture is circulated within a closed loop piping system. there are two separate water sources, one external within a closed loop, and the second one that circulates water from the tower basin over the heat exchanger. What are the differences between a closed circuit cooling tower and an open circuit cooling tower? when do you use a fluid cooler, and what are the advantage. These require more horsepower to achieve temperatures close to the open circuit. which type of cooling tower is more efficient. the cooling tower efficiency formula reads as: μ = (ti to) 100 (ti twb), which may be tough to understand by just looking at it. fundamentally, a cooling tower’s efficiency is measured in terms of approach and. Cooling towers can be classified based on several design characteristics. these are: wet or dry. mechanical draft or natural draft. induced, forced or natural draft. counter flow or cross flow. direct or indirect (open or closed circuit). let’s have a look at each of these classifications in more detail.

Closed Circuit Vs Open Circuit Cooling Towers Youtube These require more horsepower to achieve temperatures close to the open circuit. which type of cooling tower is more efficient. the cooling tower efficiency formula reads as: μ = (ti to) 100 (ti twb), which may be tough to understand by just looking at it. fundamentally, a cooling tower’s efficiency is measured in terms of approach and. Cooling towers can be classified based on several design characteristics. these are: wet or dry. mechanical draft or natural draft. induced, forced or natural draft. counter flow or cross flow. direct or indirect (open or closed circuit). let’s have a look at each of these classifications in more detail. Operationally, closed cooling towers maintain their efficiency better than open towers with plate and frame heat exchangers simply because their heat transfer capability is far less impaired by surface fouling. that’s a brief overview of the differences between open and closed cooling towers that an engineer should consider in the earliest. Liked by tsur ben david. ceo at cet enviro cooling efficiency technologies · ceo of cet enviro cooling efficiency technologies. strategy development, project planning and implementation, b2b.

Closed Circuit Vs Open Circuit Cooling Towers Mep Academy Operationally, closed cooling towers maintain their efficiency better than open towers with plate and frame heat exchangers simply because their heat transfer capability is far less impaired by surface fouling. that’s a brief overview of the differences between open and closed cooling towers that an engineer should consider in the earliest. Liked by tsur ben david. ceo at cet enviro cooling efficiency technologies · ceo of cet enviro cooling efficiency technologies. strategy development, project planning and implementation, b2b.

Comments are closed.