Digital Twin Aids In Virtual Commissioning Control Design

Digital Twin Aids In Virtual Commissioning Control Design Virtual commissioning helps you avoid these risks by identifying potential issues earlier. it uses a simulated digital twin of your machine to perform controls testing before the machine is on site or maybe even before it’s built. a digital twin of your machine also offers value once a machine is deployed. Tual commissioning with a model driven digital twin in the manufacturing and automation industry, adopting new development techniques has become a key requiremen. for success in a highly evolving, competitive market. as demands on product requirements increase, the inherent design risks can pose significant problems, threatening t.

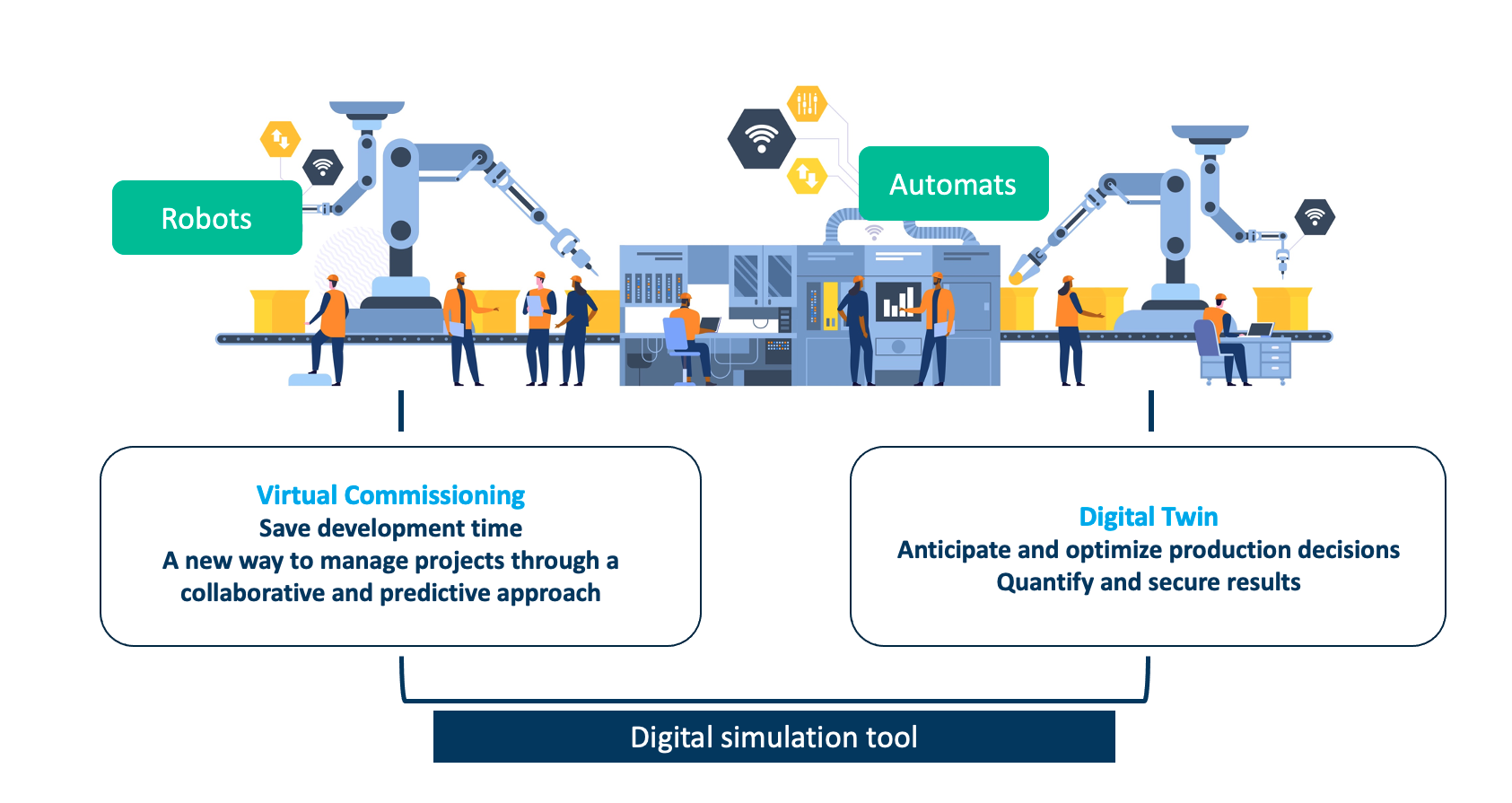

Webinar A Comprehensive Digital Twin Solution And Virtual However, the term digital twin was coined by nasa in 2010 [21] and defined as “a digital twin is an integrated multi physics, multi scale, probabilistic simulation of a vehicle or system that uses the best author name procedia computer science 00 (2019) 000–000 3 available physical models, sensor updates, fleet history, etc., to. 1.3 virtual commissioning within digital twin architectures. virtual commissioning (vc) is generally utilized for the design and verification of the control software of complex manufacturing systems due to its ability to speed up the commissioning process . in the context of dt, vc has been utilized within the robotics domain as a synchronized. Virtual commissioning allows engineers to connect the digital twin to the plc to test, refine and optimize mechanical, electrical and logical designs, and the integration between them, well before hardware is assembled on the shop floor, without the need to delay delivery or stop production. what virtual commissioning provides. This approach to modern, efficient machine design is quickly becoming a key technology for reducing costs and ensuring smarter products. the technology behind this process uses what industry 4.0 is calling a digital twin, and by using modern system level modeling tools, they are becoming an important part of the virtual commissioning process.

Virtual Commissioning It S Not Too Late To Make The Right Choice Virtual commissioning allows engineers to connect the digital twin to the plc to test, refine and optimize mechanical, electrical and logical designs, and the integration between them, well before hardware is assembled on the shop floor, without the need to delay delivery or stop production. what virtual commissioning provides. This approach to modern, efficient machine design is quickly becoming a key technology for reducing costs and ensuring smarter products. the technology behind this process uses what industry 4.0 is calling a digital twin, and by using modern system level modeling tools, they are becoming an important part of the virtual commissioning process. Commissioning a machine system involves testing and validating the behavior of the combination of all cells to ensure optimal function. with a digital twin and virtual commissioning, manufacturers can ensure minimal production downtime and create an entire virtual factory floor to detect and resolve operational missteps. The industry 4.0 machine architecture is based entirely on digital twins. thanks to their standardised communication interfaces, they make life easier for our customers throughout virtually the entire lifecycle of a machine: from virtual commissioning and control of the machine to data acquisition and the resulting value added services such as.

Creating A Digital Twin With Maplesim Commissioning a machine system involves testing and validating the behavior of the combination of all cells to ensure optimal function. with a digital twin and virtual commissioning, manufacturers can ensure minimal production downtime and create an entire virtual factory floor to detect and resolve operational missteps. The industry 4.0 machine architecture is based entirely on digital twins. thanks to their standardised communication interfaces, they make life easier for our customers throughout virtually the entire lifecycle of a machine: from virtual commissioning and control of the machine to data acquisition and the resulting value added services such as.

Virtual Commissioning And The Digital Twin Minimizing Risk In

The Digital Twin In The Manufacturing Process Five Steps How Virtual

Comments are closed.