Flow Diagram Closed Loop Cooling

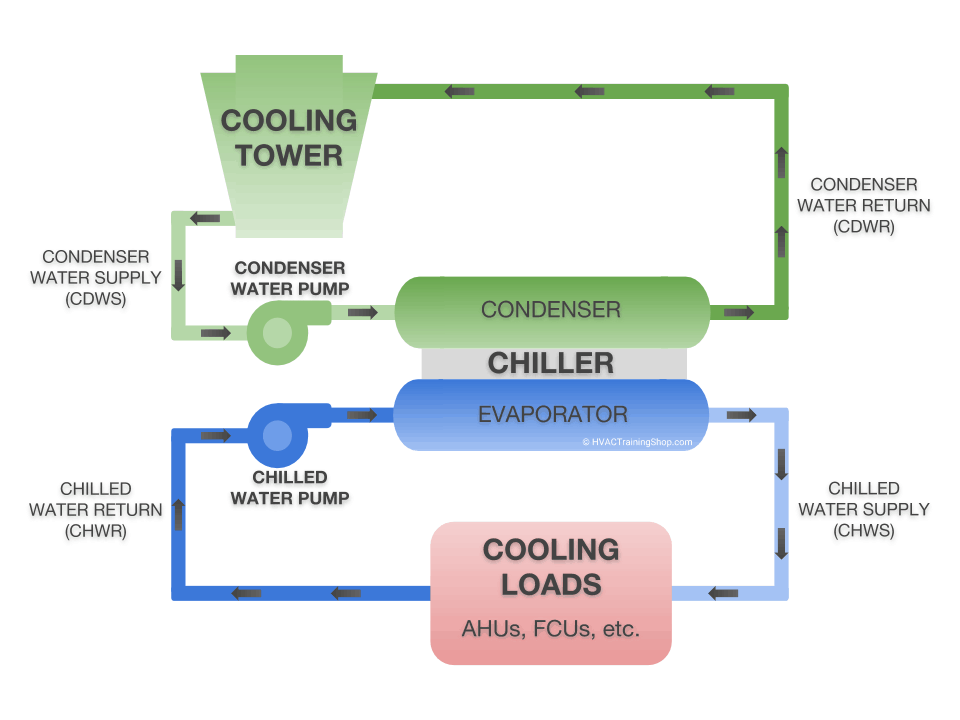

Understanding Closed Loop Cooling Water Systems The closed recirculating cooling water system evolved from methods used for the cooling of early engine designs. in a closed water system, water circulates in a closed cycle and is subjected to alternate cooling and heating without air contact. heat, absorbed by the water in the closed system, is normally transferred by a water to water. Closed circuit cooling towers, also known as evaporative fluid coolers, keep the system clean and contaminant free in a closed loop. this creates two separate fluid circuits: (1) an external circuit, in which spray water circulates over the coil and mixes with the outside air, and (2) an internal circuit, in which the process fluid to be cooled circulates inside the coil.

Closed Loop Cooling Tower Piping Schematic Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. The term closed cooling water system is somewhat of a misnomer, as virtually all systems have leaks or small losses somewhere that require makeup. (if serious corrosion has occurred, these losses may be significant.) a closed system is basically defined as a loop which has little or no evaporation, and where makeup requirements do not exceed. Design capacity – 430.0 gpm design head – 47.0 feet motor size – 10 hp. less than anticipated pump headthe pump point shift has increased flow. over design to the order of 45%. cavitational and or tower vortex can occur unless. corrective measures are applied.the pump impeller diameter could, and should be cut down. In a closed loop liquid cooling system, the cooling fluid is contained within a sealed environment that minimizes the need for regular maintenance. because the liquid does not come into contact with external contaminants, it almost never needs to be replaced or refilled. this self sustaining design ensures the liquid's level, integrity, and.

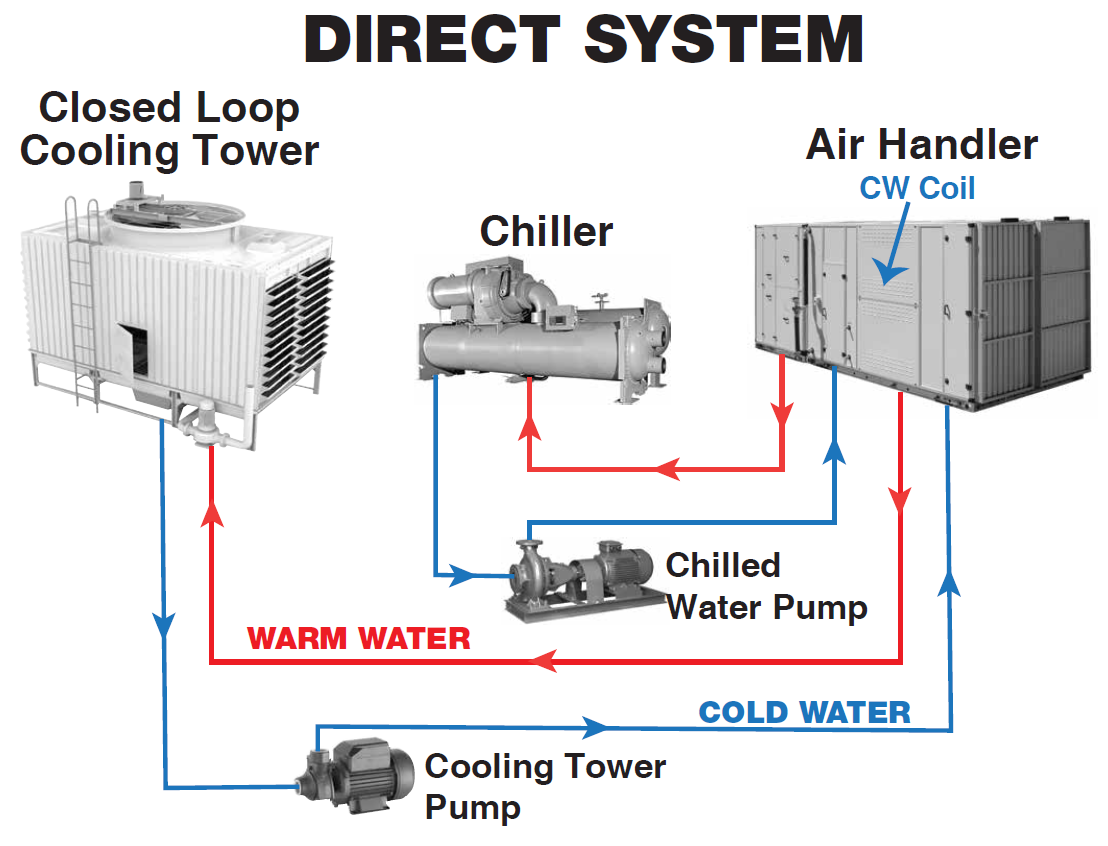

What Is Closed Loop Cooling Design capacity – 430.0 gpm design head – 47.0 feet motor size – 10 hp. less than anticipated pump headthe pump point shift has increased flow. over design to the order of 45%. cavitational and or tower vortex can occur unless. corrective measures are applied.the pump impeller diameter could, and should be cut down. In a closed loop liquid cooling system, the cooling fluid is contained within a sealed environment that minimizes the need for regular maintenance. because the liquid does not come into contact with external contaminants, it almost never needs to be replaced or refilled. this self sustaining design ensures the liquid's level, integrity, and. Closed loop technology. evapco’s wide range of closed circuit coolers, or simply “fluid coolers” provide a heat rejection alternative for engineers or end users who want (or need) to reduce water consumption and equipment maintenance, or a number of other considerations that exist with open loop cooling applications. Closed loop systems – fluidflow. in general, there are two main types of systems in which pumps can be installed, open loop and closed loop systems. open loop systems are circuits in which the pumped fluid is exposed to the local atmosphere at some point in the circuit. a typical open loop system would be a cooling tower system where the.

Closed Loop Cooling Tower Piping Schematic Closed loop technology. evapco’s wide range of closed circuit coolers, or simply “fluid coolers” provide a heat rejection alternative for engineers or end users who want (or need) to reduce water consumption and equipment maintenance, or a number of other considerations that exist with open loop cooling applications. Closed loop systems – fluidflow. in general, there are two main types of systems in which pumps can be installed, open loop and closed loop systems. open loop systems are circuits in which the pumped fluid is exposed to the local atmosphere at some point in the circuit. a typical open loop system would be a cooling tower system where the.

Liquid Cooling Closed Loop System For Cooling The Replaceable Insert

Comments are closed.