How Is A Reference Dimension Shown On A Drawing

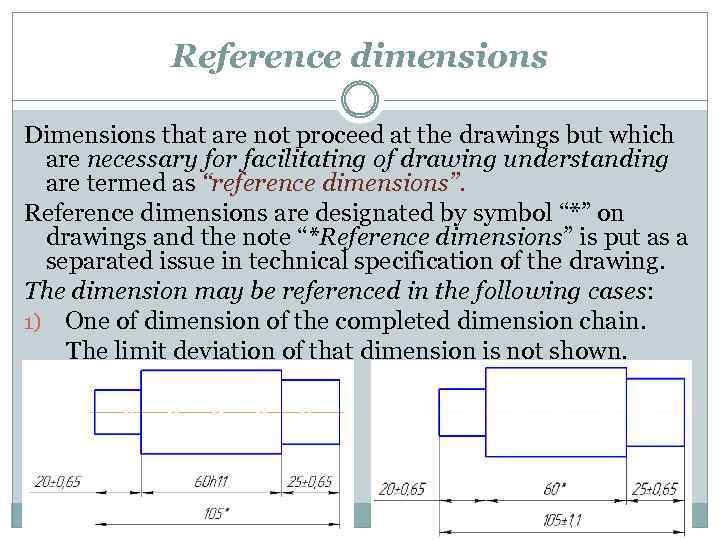

Reference Dimensions On Drawings Drawing Rjuuc Edu Np A reference dimension is just what it sounds like. it is a dimension shown for reference. in other words it is there for informational purposes only. they are not a requirement in any way. reference dimensions can be used to clarify other dimensions on a drawing. in some instances, they make a drawing easier to understand. Reference dimension. a reference dimension is a dimension on an engineering drawing provided for information only. [1] reference dimensions are provided for a variety of reasons and are often an accumulation of other dimensions that are defined elsewhere [2] (e.g. on the drawing or other related documentation).

Dimensioning On Technical Drawing Theme 4 Introduction Basic dimensions are typically used within the gd&t framework to control the location or geometry of features. the best example of when basic dimensions are used is when specifying true position. take a look at this drawing below: the basic dimensions are those dimensions in the boxes – the 30 and the 15. they do have tolerances, though, as. The symbol for a basic dimension is the dimension shown enclosed in a rectangular frame or box. this is the convention identified in the blueprint drawing standard asme y14.5. some drawings may list a basic dimension not in a rectangular frame but instead the dimension will be followed by a bsc. notation. Geometric dimensioning and tolerancing (gd&t) is a crucial aspect in ensuring product quality across various industries, from automotive and aerospace to electronics and medical devices. by providing a systematic approach to define and control the size, shape, and position of parts, gd&t helps in maintaining tight tolerances and ensuring that. All dimensions are also based on the datum reference framework as a type of coordinate system. dimensions can be one of the following forms: reference dimension: features that have reference dimensions are for reference only, for visualization purposes. a reference dimension is called out on a drawing with parenthesis — i.e. (0.525) — and.

1 4a Placing Of Dimension Systems In Engineering Drawing Aligned And Geometric dimensioning and tolerancing (gd&t) is a crucial aspect in ensuring product quality across various industries, from automotive and aerospace to electronics and medical devices. by providing a systematic approach to define and control the size, shape, and position of parts, gd&t helps in maintaining tight tolerances and ensuring that. All dimensions are also based on the datum reference framework as a type of coordinate system. dimensions can be one of the following forms: reference dimension: features that have reference dimensions are for reference only, for visualization purposes. a reference dimension is called out on a drawing with parenthesis — i.e. (0.525) — and. Leader line is the thin solid line used to indicate the feature with which a dimension, note, or symbol is associated. tolerance is the amount a particular dimension is allowed to vary. plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. Use appropriate units: choose the appropriate units of measurement for the drawing. in most cases, millimeters are the preferred unit for engineering drawings. however, inches or other units may be used in certain situations. apply tolerances: tolerances specify the allowable variation in a dimension.

Dimensioning Standards Leader line is the thin solid line used to indicate the feature with which a dimension, note, or symbol is associated. tolerance is the amount a particular dimension is allowed to vary. plus and minus dimensioning is the allowable positive and negative variance from the dimension specified. Use appropriate units: choose the appropriate units of measurement for the drawing. in most cases, millimeters are the preferred unit for engineering drawings. however, inches or other units may be used in certain situations. apply tolerances: tolerances specify the allowable variation in a dimension.

Comments are closed.