How To Improve Order Picking Accuracy Warehouse Improvements

How To Improve Order Picking Accuracy Warehouse Improvements The most time consuming part of the order picking process is traveling, which takes up 55% of the warehouse selector’s time, on average, followed by paperwork and other activities (20%), searching (15%) and extracting (10%), according to research from the georgia tech supply chain and logistics institute. Warehouse order picking tips. 1. organize with popular items in mind. “put the popular items nearest. if half of the orders you get come from 10% of the products you have in the inventory, put these items nearest the entrance of the picking area. sort according to popularity, putting least popular items at the back.

How To Improve Order Picking Accuracy Warehouse Improvements To calculate it, find the number of accurate orders you’ve fulfilled, divide it by the number of total orders fulfilled, and multiply that number by 100. order accuracy rate = (total orders fulfilled accurately total orders fulfilled) * 100. let’s walk through a quick example. if you fulfilled 100 orders, and 2 of them had mistakes, then. The future of order picking in warehouse management is shaped by advancements in automation and robotics, data analytics and predictive modeling, and the growing need for sustainability. implementing best practices and embracing advancements can help warehouse managers improve the order picking process and stay competitive in the industry. Considering the impact warehouse picking errors’ can have on your business, you can use as many as 21 different tactics and ideas to reduce any mistakes. these are, in no particular order: measure performance. map your picking process. ensure the accuracy of your inventory. conduct regular inventory checks. 3. leverage order picking technologies. integrating advanced order picking technologies can drastically improve pick rates by increasing accuracy and efficiency. consider investing in the following tools: pick to light systems: these systems use light signals to guide pickers to the correct item locations, reducing errors and search time.

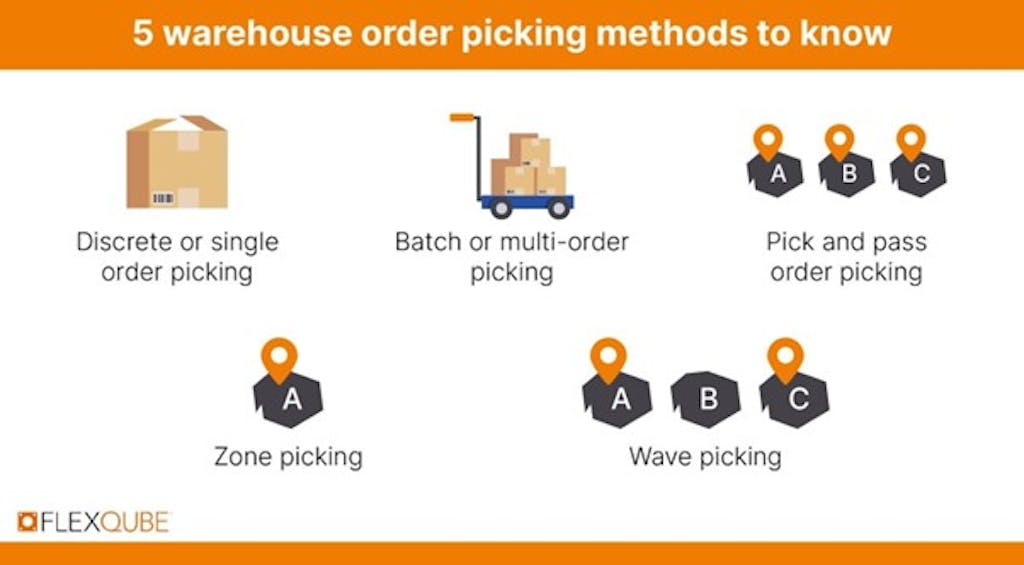

How To Improve Order Picking In Your Warehouse Flexqube Considering the impact warehouse picking errors’ can have on your business, you can use as many as 21 different tactics and ideas to reduce any mistakes. these are, in no particular order: measure performance. map your picking process. ensure the accuracy of your inventory. conduct regular inventory checks. 3. leverage order picking technologies. integrating advanced order picking technologies can drastically improve pick rates by increasing accuracy and efficiency. consider investing in the following tools: pick to light systems: these systems use light signals to guide pickers to the correct item locations, reducing errors and search time. It can be tracked at the order level, indicating the time taken to pick a complete order by using the following calculation: picking rate = total picks. total time spent. according to warehousing and fulfillment, the average of the industry is around 71 items per hour which is a good picking rate. it is a key indicator for picking performance. To measure order picking efficiency, we recommend you consider these key metrics: order picking accuracy: tracks the percentage of accurate orders picked. calculation: (number of accurate orders total number of orders picked) x 100. order picking rate: measures the number of lines items picked per hour or per picker.

How To Improve Order Picking Accuracy Warehouse Improvements It can be tracked at the order level, indicating the time taken to pick a complete order by using the following calculation: picking rate = total picks. total time spent. according to warehousing and fulfillment, the average of the industry is around 71 items per hour which is a good picking rate. it is a key indicator for picking performance. To measure order picking efficiency, we recommend you consider these key metrics: order picking accuracy: tracks the percentage of accurate orders picked. calculation: (number of accurate orders total number of orders picked) x 100. order picking rate: measures the number of lines items picked per hour or per picker.

How To Improve Order Picking In Your Warehouse Flexqube

How To Improve Order Picking Accuracy In Your Warehouse

Comments are closed.