How To Pick A Cooling Tower Comparing Open And Closed Loop Towers

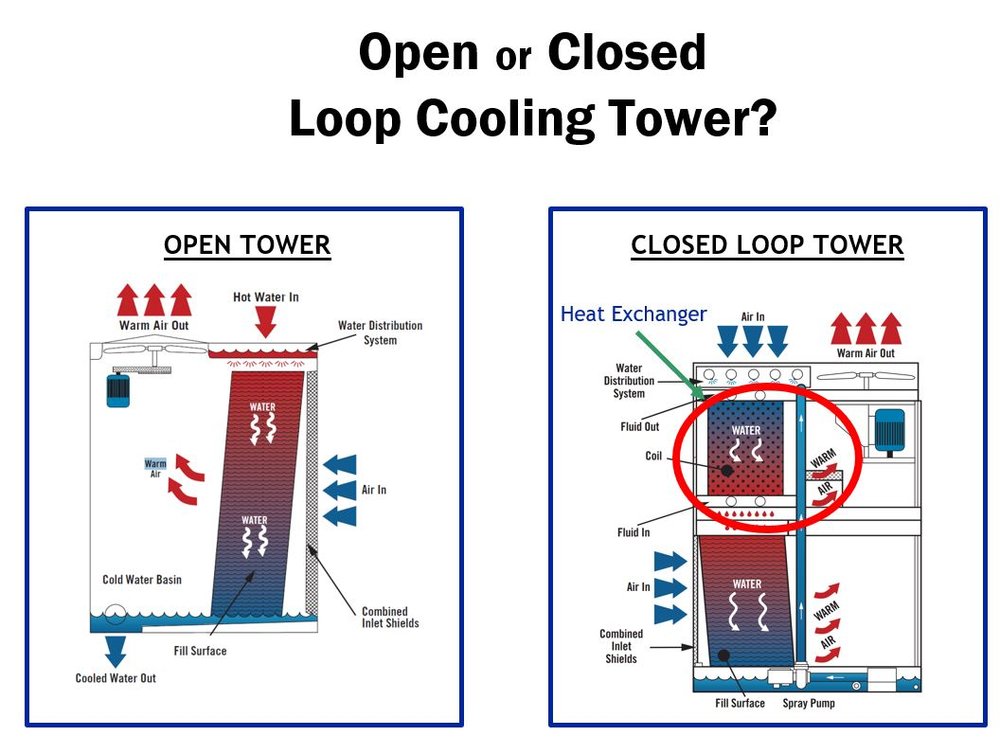

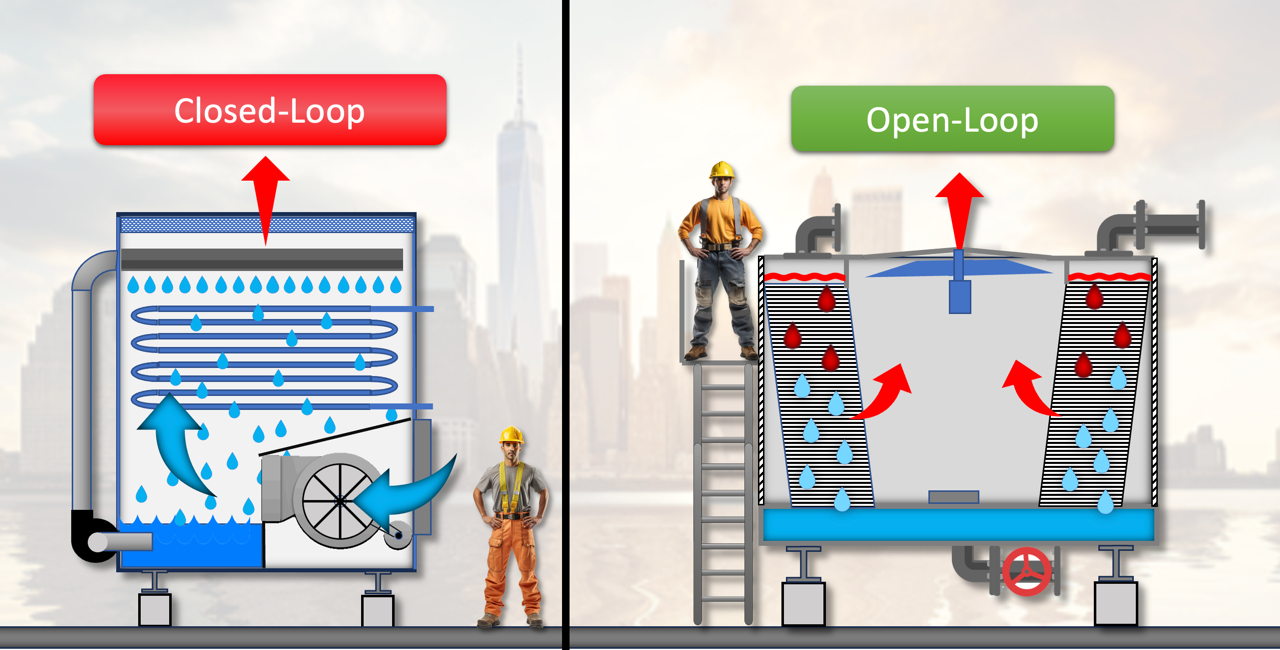

How To Pick A Cooling Tower Comparing Open And Closed Loop Towers When comparing a closed cooling tower’s cost to that of an open cooling tower with a plate and frame heat exchanger, the closed tower tends to have a higher first cost unless you look at the complete cooling tower system with adjacent components. this is because one must remember that open cooling towers often require filtration equipment and. Closed loop vs open loop operation. in a closed circuit cooling tower, the process fluid, which could be water, or a water glycol mixture is circulated within a closed loop piping system. there are two separate water sources, one external within a closed loop, and the second one that circulates water from the tower basin over the heat exchanger.

Closed Circuit Vs Open Circuit Cooling Towers Mep Academy Different types of closed circuit cooling tower systems. another closed circuit cooling tower system involves a separate heat exchanger package along with an open cooling tower. the fluid on the hot side of the heat exchanger also never makes direct contact with the air. this allows the heat exchanger to be put inside, protected from the. Cooling towers play a critical role in maintaining the temperature of industrial and commercial operations. but understanding the different types of cooling towers, their functions, and their benefits can be confusing. in this post, we’ll explore the intricacies of open loop and closed loop cooling towers to help building managers and industrial operators make informed […]. Ek's head of easy cooling business unit, jaka klemenčič, talks about the main differences and pros and cons of open and closed loops in this ek expo video. i. The choice between open circuit cooling towers and closed loop circuit cooling towers depends on specific requirements and constraints. open circuit cooling towers provide cost effective cooling solutions with high energy efficiency, but they consume more water and require water treatment.

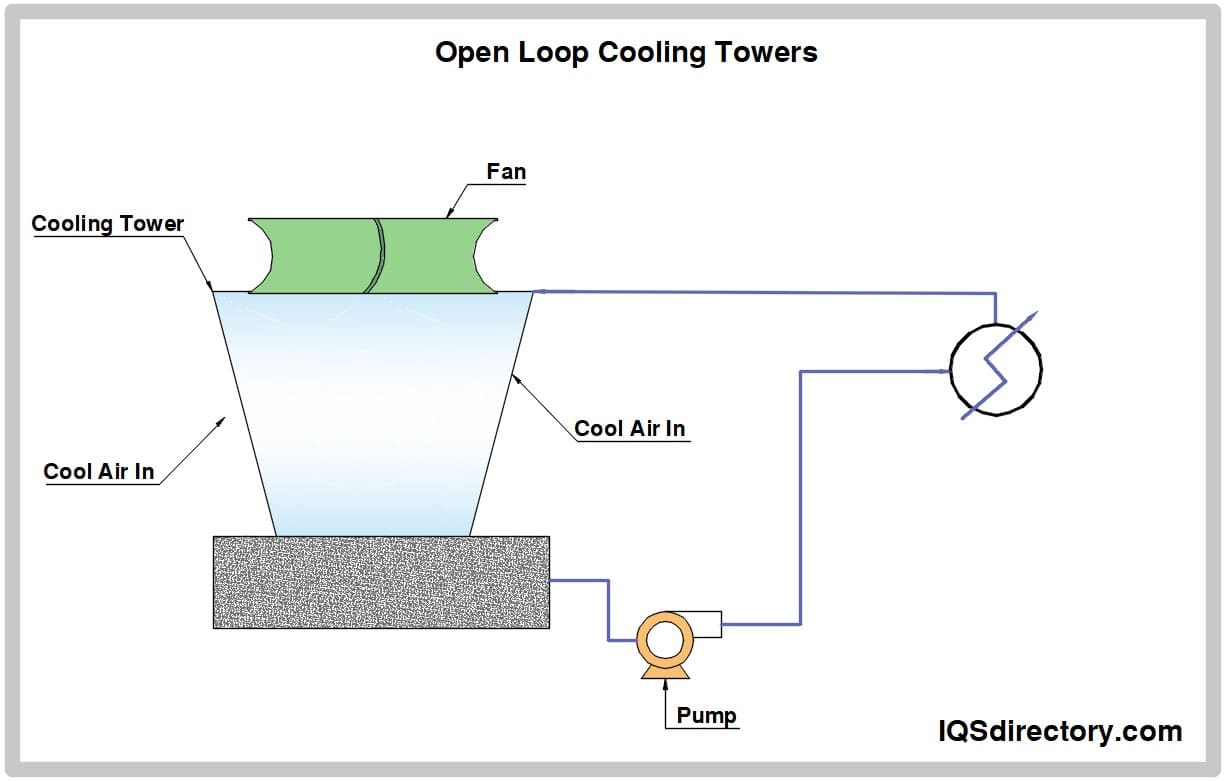

Open Loop And Closed Loop Cooling Towers Operation Types 59 Off Ek's head of easy cooling business unit, jaka klemenčič, talks about the main differences and pros and cons of open and closed loops in this ek expo video. i. The choice between open circuit cooling towers and closed loop circuit cooling towers depends on specific requirements and constraints. open circuit cooling towers provide cost effective cooling solutions with high energy efficiency, but they consume more water and require water treatment. In open loop and closed loop cooling towers, the fill media facilitates the contact between air and the water surface. this media helps the water spread into thin, flowing layers, maximizing the surface area exposed to the air flow. fill media is typically made from materials such as polypropylene, wood, or pvc. Open cooling towers expose process cooling water to the atmosphere, typically as part of a chiller system loop. open towers use an efficient, simple, and economical design. all components in an open system must be compatible with the oxygen introduced via the cooling tower. closed circuit cooling towers completely isolate the process cooling.

How To Pick A Cooling Tower Comparing Open And Closed Loop Towers In open loop and closed loop cooling towers, the fill media facilitates the contact between air and the water surface. this media helps the water spread into thin, flowing layers, maximizing the surface area exposed to the air flow. fill media is typically made from materials such as polypropylene, wood, or pvc. Open cooling towers expose process cooling water to the atmosphere, typically as part of a chiller system loop. open towers use an efficient, simple, and economical design. all components in an open system must be compatible with the oxygen introduced via the cooling tower. closed circuit cooling towers completely isolate the process cooling.

How To Pick A Cooling Tower Comparing Open And Closed Loop Towers

Comments are closed.