Magnetic Particle Inspection And Examination Non Destructive Testing

Magnetic Particle Inspection And Examination Non Destructive Testing Advantages of magnetic particle testing. surface and near surface inspection: mt is highly effective at detecting surface and slightly subsurface discontinuities. quick and relatively simple: the process is relatively quick, making it suitable for time sensitive projects. cost effective: compared to some other ndt methods, mt is relatively low. In theory, magnetic particle inspection (mpi) is a relatively simple concept. it can be considered as a combination of two nondestructive testing methods: magnetic flux leakage testing and visual testing. consider the case of a bar magnet. it has a magnetic field in and around the magnet. any place that a magnetic line of force exits or enters.

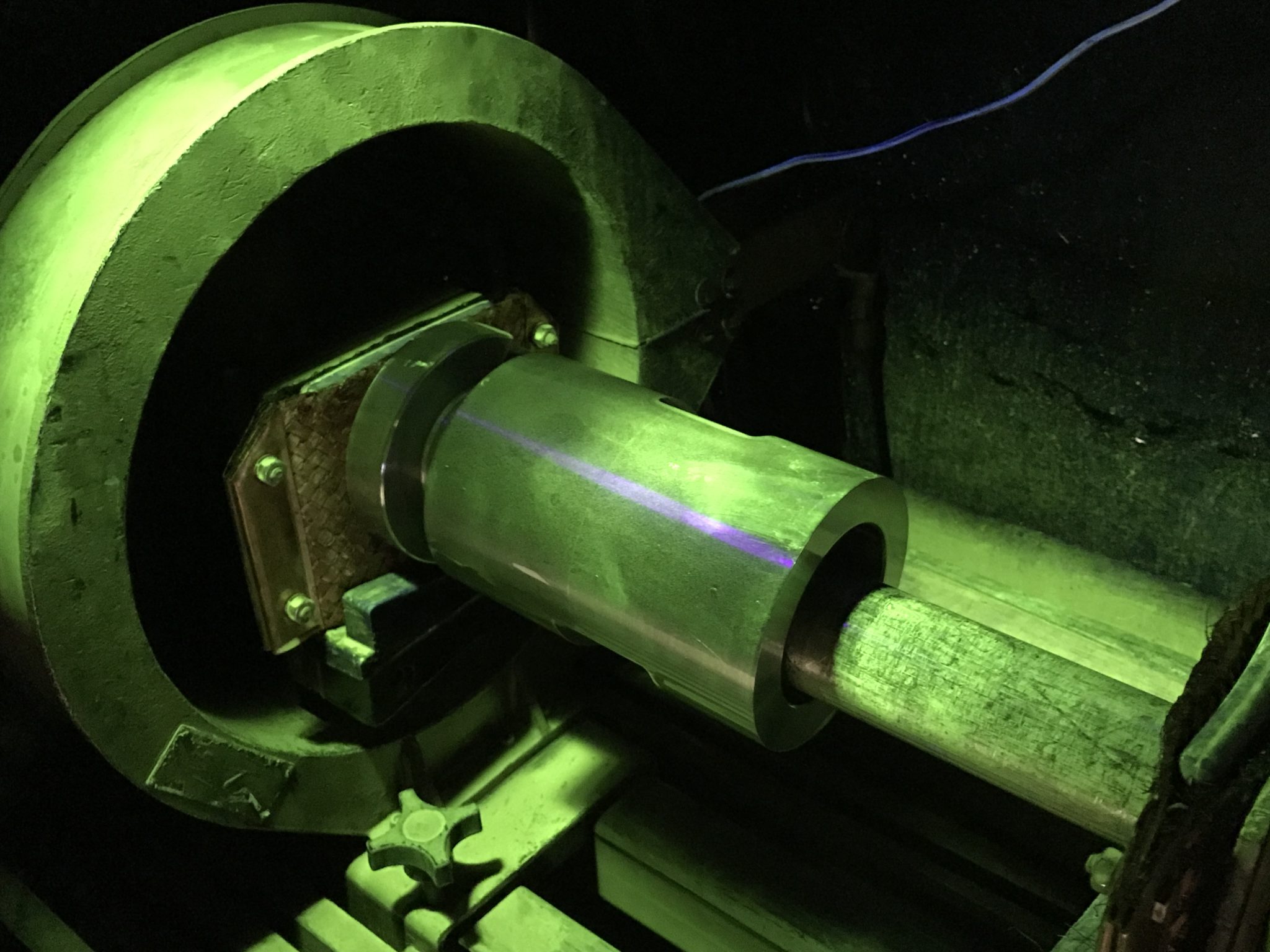

Magnetic Particle Inspection Non Destructive Testing Ndt Stegman Magnetic particle inspection (mpi) is a nondestructive testing process where a magnetic field is used for detecting surface, and shallow subsurface, discontinuities in ferromagnetic materials. examples of ferromagnetic materials include iron, nickel, cobalt, and some of their alloys. the process puts a magnetic field into the part. Magnetic particle inspection (mpi) is one of the most widely used non destructive inspection methods for locating surface or near surface defects or flaws in ferromagnetic materials. mpi is basically a combination of two ndt methods: visual inspection and magnetic flux leakage testing. developed in the usa, magnetic particle inspection is. Magnaflux . ux 1 847 657 5300the importance of magnetic particle inspectionmagnetic particle inspection (mpi) is a nondestruct. ve testing (ndt) method that does not harm the parts being inspected. mpi is a cost efective and reliable testing method commonly used to identify surfa. e and slightly subsurface discontinuities in. Welcome to the fascinating world of non destructive testing (ndt), specifically the method of magnetic particle inspection (mt). whether you’re just starting out or looking to brush up on your basics, magnetic particle testing is a crucial technique for identifying surface and near surface flaws in ferromagnetic materials.

Magnetic Particle Testing Mt Magnaflux . ux 1 847 657 5300the importance of magnetic particle inspectionmagnetic particle inspection (mpi) is a nondestruct. ve testing (ndt) method that does not harm the parts being inspected. mpi is a cost efective and reliable testing method commonly used to identify surfa. e and slightly subsurface discontinuities in. Welcome to the fascinating world of non destructive testing (ndt), specifically the method of magnetic particle inspection (mt). whether you’re just starting out or looking to brush up on your basics, magnetic particle testing is a crucial technique for identifying surface and near surface flaws in ferromagnetic materials. Magnetic particle inspection (mpi) is a non destructive metal testing method. it is used to detect surface and near surface discontinuities in ferromagnetic metal components. magnetic particle inspection uses metal particles to identify cracks and other imperfections in the tested piece. this guide will provide an overview of magnetic particle. Extensive research and industry applications have been conducted to verify its effectiveness. however, it is crucial to discuss the status of magnetic particle inspection, especially in light of advancements in image processing technology and the emergence of the concept of non destructive testing 4.0.

Magnetic Particle Inspections Mpi It Is A Non Destructive Testing Magnetic particle inspection (mpi) is a non destructive metal testing method. it is used to detect surface and near surface discontinuities in ferromagnetic metal components. magnetic particle inspection uses metal particles to identify cracks and other imperfections in the tested piece. this guide will provide an overview of magnetic particle. Extensive research and industry applications have been conducted to verify its effectiveness. however, it is crucial to discuss the status of magnetic particle inspection, especially in light of advancements in image processing technology and the emergence of the concept of non destructive testing 4.0.

Comments are closed.