Material Science Ttt Diagram Traansformation Of Steels Ferrous

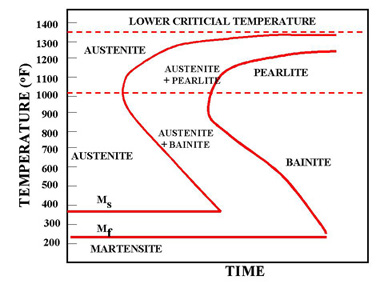

Material Science Ttt Diagram Traansformation Of Steels Ferrous Time temperature transformation (ttt ) diagram. t (time) t (temperature) t (transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy. Salt bath i (fig. 1) is maintained at austenetising temperature (780 ̊c for eutectoid steel). salt bath ii (fig. 2) is maintained at specified temperature at which transformation is to be determined (below ae1), typically 700 250°c for eutectoid steel. bath iii which is a cold water bath is maintained at room temperature.

Ttt Diagram Basic Ttt Diagram For Steel Eutectoid Steel Treatment which involves transformation of austenite is largely, if not entirely, determined by those factors which influence the time required for isothermal transform ation, and hence, the shape and position of the curves which comprise the 1 t diagram. material used each diagram contains sufficient inform ation to identify the steel to. Fig. 4: ttt diagram for eutectoid steel a real ttt diagram is somewhat more complicated (fig. 5). consider for example a hypoeutectoid steel – the first phase to form would be ferrite with transformation becoming possible just below the ae3 temperature. widmanst¨atten ferrite then begins to grow as a displacive transformation in which. Part ib materials science & metallurgy h. k. d. h. bhadeshia course a, metals and alloys lecture 10: ferrous alloys fe–c phase diagram the vast majority of steels are in the austenitic condition at tempera tures in excess of 900 c. austenite has a cubic–close packed crystal structure and tends to decompose into ferrite (body–centered. Ttt diagrams are also called isothermal (constant temperature) transformation diagrams, because ttt diagrams give the kinetics of isothermal transformations. for every composition of steel a different ttt diagram should be drawn. 8.3.1. determination of the ttt diagram for eutectoid steel.

Time Temperature Transformation Ttt Diagram Metallurgy For Dummies Part ib materials science & metallurgy h. k. d. h. bhadeshia course a, metals and alloys lecture 10: ferrous alloys fe–c phase diagram the vast majority of steels are in the austenitic condition at tempera tures in excess of 900 c. austenite has a cubic–close packed crystal structure and tends to decompose into ferrite (body–centered. Ttt diagrams are also called isothermal (constant temperature) transformation diagrams, because ttt diagrams give the kinetics of isothermal transformations. for every composition of steel a different ttt diagram should be drawn. 8.3.1. determination of the ttt diagram for eutectoid steel. There are two main types of transformation diagram that are helpful in selecting the optimum steel and processing route to achieve a given set of properties. these are time temperature transformation (ttt) and continuous cooling transformation (cct) diagrams. cct diagrams are generally more appropriate for engineering applications as components. Davenport and bain made a pivotal breakthrough in our understanding of bulk phase kinetics when they introduced the first experimental time temperature transformation (ttt) diagrams in 1930, which were based on a detailed and extensive study of steel phase transformation kinetics [1]. these ttt diagrams were revolutionary because they offered a.

Ttt Diagram Of Steel Material Science Free Energy Diagram There are two main types of transformation diagram that are helpful in selecting the optimum steel and processing route to achieve a given set of properties. these are time temperature transformation (ttt) and continuous cooling transformation (cct) diagrams. cct diagrams are generally more appropriate for engineering applications as components. Davenport and bain made a pivotal breakthrough in our understanding of bulk phase kinetics when they introduced the first experimental time temperature transformation (ttt) diagrams in 1930, which were based on a detailed and extensive study of steel phase transformation kinetics [1]. these ttt diagrams were revolutionary because they offered a.

2 Typical Ttt Diagram For Steel Hoe96 Download Scientific Diagram

Comments are closed.