Module 1 Introduction To Air Cooled And Water Cooled Chillers

Module 1 Introduction To Air Cooled And Water Cooled Chillers Youtube This 20 minute module is the first in a 3 part series covering basic chiller operations, chiller part information and using the parts navigator ordering tool. The reason for this difference is that water cooled chillers are usually installed inside and operate at lower condenser pressures, and outdoor air cooled chillers operate at higher condenser pressures. either way, proper commercial chiller repair can extend the life of your equipment, so don’t neglect it!.

How Air And Water Cooled Chillers Work Youtube The difference between water cooled and air cooled chillers are in how the heat is rejected from the system. in a water cooled system, water is used as the method for heat rejection, while air cooled chillers use air as the heat rejection method, hence the naming. if you haven’t seen our video on refrigerant circuit, then be sure to watch. Water cooled chillers cost more upfront and require regular maintenance due to their reliance on cooling towers, condenser water pumps and other parts that air cooled chillers don’t have. the upsides include a longer lifespan, quiet operation and greater energy efficiency. chiller systems are complex and you should always consult with an. Cost – many air cooled chillers are part of an easy to install packaged system that includes the condenser, compressor, and evaporator. quicker installation and fewer components translate to lower upfront and maintenance costs. energy efficiency – while water cooled chillers are best known for their energy efficiency, air cooled units. Cyk water to water compound centrifugal chiller heat pump. two electric motor driven centrifugal compressors deliver simultaneous hot water and chilled water @ 42 °f (5 °c) 170 °f (77 °c) turndown: 25% of design capacity made possible through vsd and compressor vi control technologies. at 400 tons (1,406 kw) cooling and 7,000 mbh (2,051.

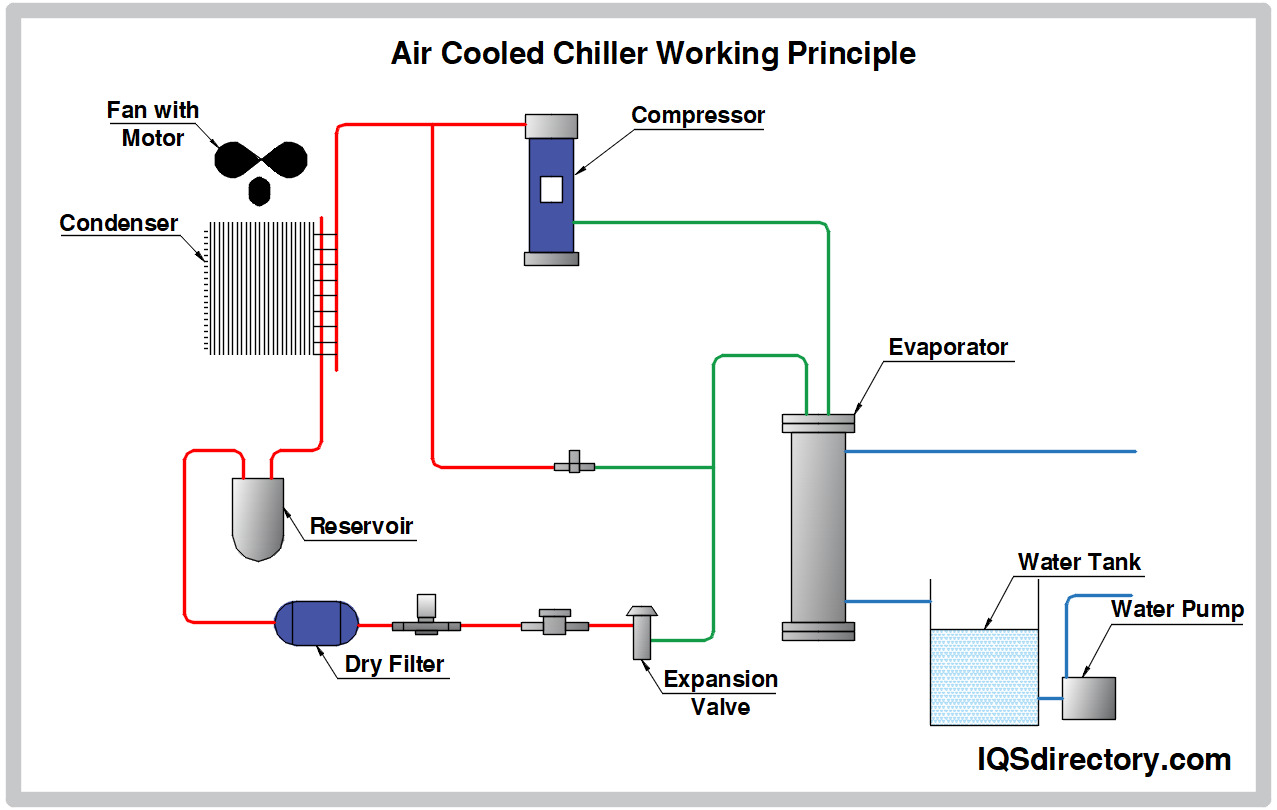

Air Cooled Chillers Principle Types Applications And Benefits Cost – many air cooled chillers are part of an easy to install packaged system that includes the condenser, compressor, and evaporator. quicker installation and fewer components translate to lower upfront and maintenance costs. energy efficiency – while water cooled chillers are best known for their energy efficiency, air cooled units. Cyk water to water compound centrifugal chiller heat pump. two electric motor driven centrifugal compressors deliver simultaneous hot water and chilled water @ 42 °f (5 °c) 170 °f (77 °c) turndown: 25% of design capacity made possible through vsd and compressor vi control technologies. at 400 tons (1,406 kw) cooling and 7,000 mbh (2,051. Chillers with air cooled condensers utilize air to refrigerant heat exchangers, while water cooled chillers reject the heat via cooling tower or dry cooler. an air cooled condenser uses ambient air for cooling and condensing the refrigerant gas back to a liquid. it usually located inside the chiller or remotely, but ultimately it dissipates the. These chillers use air to cool water and other fluids circulating through the system, helping to lower the temperature of equipment, processes, and areas by absorbing and removing heat. air cooled industrial chillers comprise a compressor, an evaporator, a condenser, and an expansion valve.

How Air And Water Cooled Chillers Work Atelier Yuwa Ciao Jp Chillers with air cooled condensers utilize air to refrigerant heat exchangers, while water cooled chillers reject the heat via cooling tower or dry cooler. an air cooled condenser uses ambient air for cooling and condensing the refrigerant gas back to a liquid. it usually located inside the chiller or remotely, but ultimately it dissipates the. These chillers use air to cool water and other fluids circulating through the system, helping to lower the temperature of equipment, processes, and areas by absorbing and removing heat. air cooled industrial chillers comprise a compressor, an evaporator, a condenser, and an expansion valve.

How Air And Water Cooled Chillers Work Atelier Yuwa Ciao Jp

Air Cooled And Water Cooled Chillers Explained The Engineering Mindset

Comments are closed.