Optimize Picking Accuracy With Accuracy Reports

Optimize Picking Accuracy With Ant Trackers Ant Lab Configuration 🎥 want to optimize your warehouse operations? 📦🔍 check out how using an order accuracy report can save time and increase efficiency! 💼 #warehousemanagem. 3.2 picking accuracy. picking accuracy is the percentage of orders picked without errors. high picking accuracy means less returns and more customer satisfaction. the picking process can be one of the most labour intensive steps in your warehousing. implement strategies like multi order picking to boost performance.

How To Improve Picking Accuracy Pickit 3 2 Documentation Optimize warehouse layout: a well organized warehouse layout can significantly reduce the time it takes to pick items and the likelihood of errors. grouping commonly picked items together, ensuring clear labeling, and minimizing travel distances between picking locations can improve efficiency and accuracy. Therefore, we have prepared a list of best practices to reduce errors during the picking process. 1. implement a barcode scanning system across the warehouse. a barcode scanning system can drastically reduce fulfillment errors by electronically transmitting data tied to skus or purchase orders. The importance of picking efficiently. any inefficiency in picking can create a domino effect that disrupts the entire supply chain. it can lead to delays, inaccuracies, frustrated customers, and lost sales. hence, a swift and accurate picking process is crucial for overall warehouse productivity. 7. order picking accuracy. order picking accuracy measures the frequency at which items are correctly picked from the inventory against customer orders. this kpi is imperative in warehouse operations, giving management a line of sight into the reliability of their picking process. (number of accurate picks total picks) x 100 = order picking.

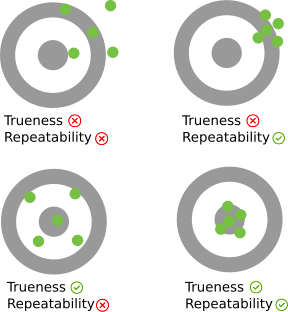

How To Improve Picking Accuracy The importance of picking efficiently. any inefficiency in picking can create a domino effect that disrupts the entire supply chain. it can lead to delays, inaccuracies, frustrated customers, and lost sales. hence, a swift and accurate picking process is crucial for overall warehouse productivity. 7. order picking accuracy. order picking accuracy measures the frequency at which items are correctly picked from the inventory against customer orders. this kpi is imperative in warehouse operations, giving management a line of sight into the reliability of their picking process. (number of accurate picks total picks) x 100 = order picking. Continuous improvement and feedback loop. improving warehouse picking speed and accuracy hinges on a cycle of order feedback and refinement. the key lies in listening to the order pickers, analyzing order performance data, and embracing lean principles to streamline the order process. Good accuracy can only be obtained with both good trueness and good repeatability. picking accuracy overview the picking accuracy of an application depends on many components. to improve it, it is important to first identify the main sources of inaccuracy. the diagram below introduces all the components affecting picking accuracy.

Optimize Picking Accuracy With Accuracy Reports Youtube Continuous improvement and feedback loop. improving warehouse picking speed and accuracy hinges on a cycle of order feedback and refinement. the key lies in listening to the order pickers, analyzing order performance data, and embracing lean principles to streamline the order process. Good accuracy can only be obtained with both good trueness and good repeatability. picking accuracy overview the picking accuracy of an application depends on many components. to improve it, it is important to first identify the main sources of inaccuracy. the diagram below introduces all the components affecting picking accuracy.

6 Ways To Improve Picking Accuracy Falcon Fulfillment

Comments are closed.