Pcb Layout Guidelines Can Bus Pcb Circuits

Designing Can Bus Circuitry Can Bus Pcb Layout Guidelines 2022 Designing can bus circuitry: can bus pcb layout guidelines. there are three main components in a can bus node: the can bus controller implements all the low level features of the network protocol, iso 11898–1, while the transceiver communicates with the physical layer. different transceivers are required for different physical layers, such as. The termination resistors are used to suppress electrical reflections on the bus. the termination resistor value is dependent on the number of nodes present in the network, and these values can be in the range of 100 to 130 Ω. typically, a nominal value of 120 Ω is placed between the can h and can l at both end points of the can network.

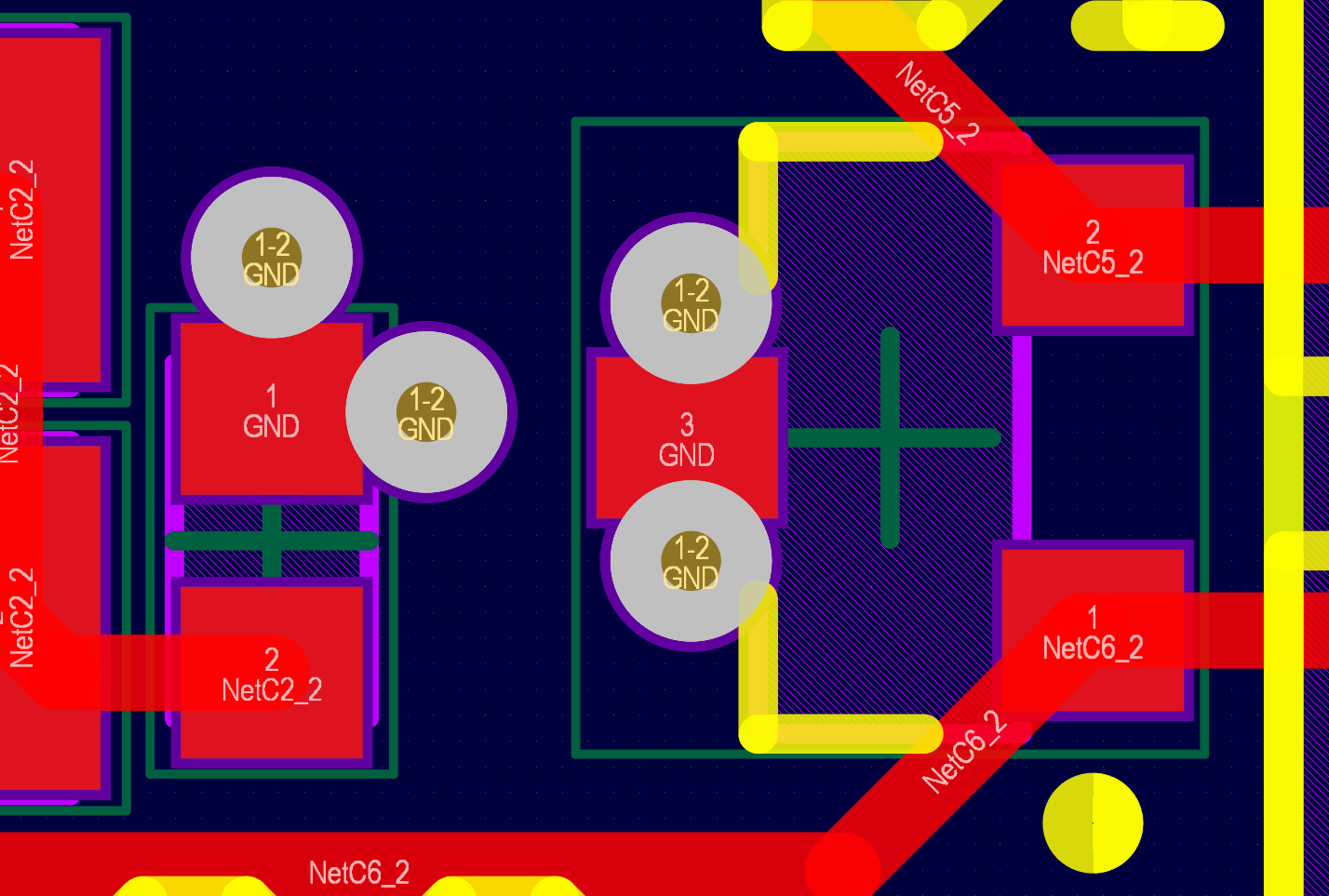

Designing Can Bus Circuitry Can Bus Pcb Layout Guidelines A can bus line must be terminated by proper resistors. these resistors help to prevent electrical reflections on the bus and ensure the bus gets the correct dc levels. the value of the termination resistor depends on the number of nodes present in the network. usually, the range varies from 100 to 130Ω. pcb design tips for a reliable can bus. Remember to provide for 120ohm termination resistors (across the can bus lines) at the transmitting end and the last receiver on the bus. connector: should be fine as long as the contacts are clean. separate the can bus pins from other high speed pins with a ground pin in between. 1.1 topology. this protocol has been developed by bosch in the 1980’s and is now widely used, not only in the automotive industry, but also in the industrial segment. can, controller area network, protocol allows serial half duplex multimaster communication between various ecus through a multiplexed bus. it therefore limits the number of wires. This application report can help system designers implement best practices and understand pcb layout options when designing platforms. this document is intended for audiences familiar with pcb manufacturing, layout, and design. 1.2 critical signals. a primary concern when designing a system is accommodating and isolating high speed signals.

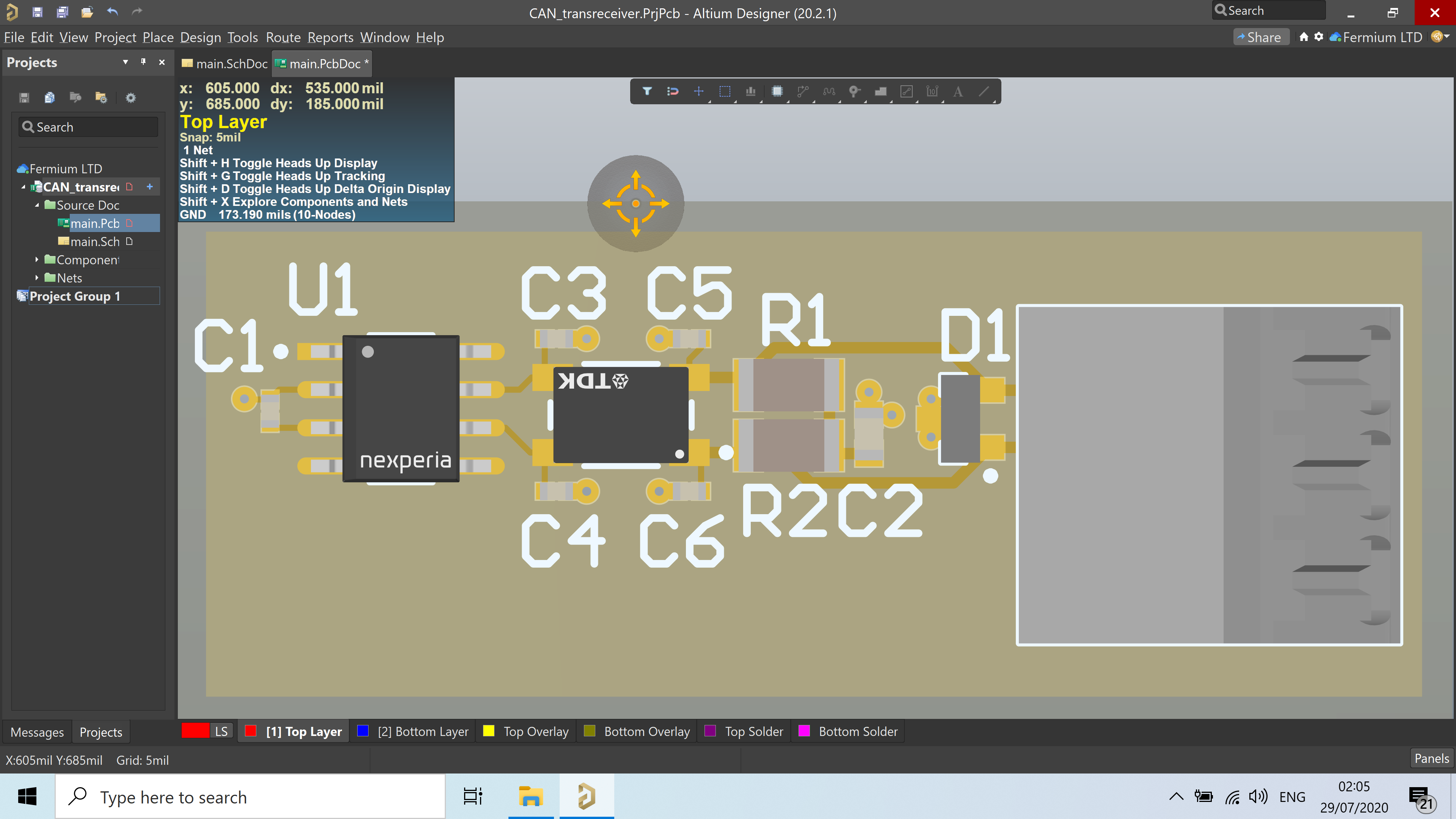

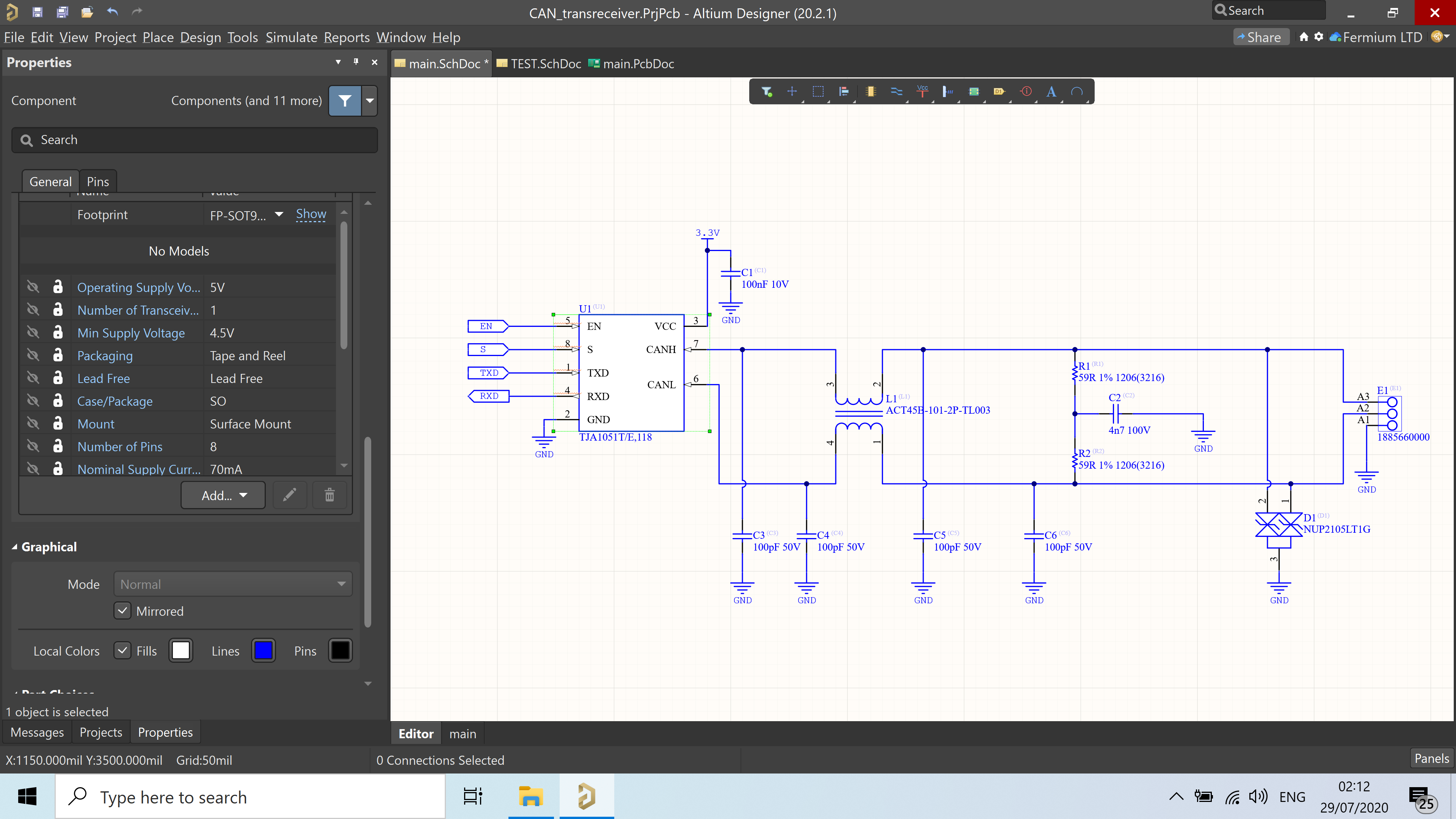

Designing Can Bus Circuitry Can Bus Pcb Layout Guidelines 1.1 topology. this protocol has been developed by bosch in the 1980’s and is now widely used, not only in the automotive industry, but also in the industrial segment. can, controller area network, protocol allows serial half duplex multimaster communication between various ecus through a multiplexed bus. it therefore limits the number of wires. This application report can help system designers implement best practices and understand pcb layout options when designing platforms. this document is intended for audiences familiar with pcb manufacturing, layout, and design. 1.2 critical signals. a primary concern when designing a system is accommodating and isolating high speed signals. The first step is designing your circuit in a single schematic document, using ports for input and outputs, similarly to what you would do for hierarchical design. figure 7. complete circuit with input and output ports. using the explorer panel, create a new “managed schematic sheets” folder. figure 8. The reason pcb layout becomes more and more important is because of the trend to faster, higher integrated, smaller form factors, and lower power electronic circuits. the higher the switching frequencies are, the more radiation occurs on a pcb. with good layout, many emi problems can be minimized to meet the required specifications.

.png)

Designing Can Bus Circuitry Can Bus Pcb Layout Guidelines The first step is designing your circuit in a single schematic document, using ports for input and outputs, similarly to what you would do for hierarchical design. figure 7. complete circuit with input and output ports. using the explorer panel, create a new “managed schematic sheets” folder. figure 8. The reason pcb layout becomes more and more important is because of the trend to faster, higher integrated, smaller form factors, and lower power electronic circuits. the higher the switching frequencies are, the more radiation occurs on a pcb. with good layout, many emi problems can be minimized to meet the required specifications.

Comments are closed.