Schematic Diagram Of The Air Mist Cooling Device For The Induction Coil

Schematic Diagram Of The Air Mist Cooling Device For The Induction Coil As we reported earlier, an air mist cooling approach can be used to minimize the coil temperature during the induction heating stage after installing wds heat insulation material (he et al., 2021. Fig. 1.chematic diagram of the air mist cooling device for the induction coil in the eicast system. (online version s in color.) 1 air compressor, 2 globe valve, 3 pressure gage, 4 flowmeter, 5 water tank, 6 submersible pump, 7 compression release valve, 8 filter, 9 one way valve, 10 air mist generating device, 11 induction coil,.

Schematic Diagram Of The Air Mist Cooling Device For The Induction Coil Schematic diagram of the air mist cooling device for the induction coil in the eicast system. (online version in color.) temperature curve of the upper surface of the nozzle brick and fe c alloy. A novel air mist cooling method was adopted to reduce the coil temperature in this paper. firstly, the air mist generating device was optimized. the results reveal that the optimized air mist generating device can improve the cooling effect dramatically. and then, the influence of water flow and gas flow on the cooling effect of the coil was. » section 1: coil basics the induction coil determines how effectively and efficiently a workpiece is heated. induction coils are water cooled copper conductors made of copper tubing that is readily formed into the shape of the coil for the induction heating process. induction heating coils do not themselves get hot as water flows through them. Owing to the heat transfer from high temperature liquid steel, the temperature of the coil in the electromagnetic induction controlled automated steel teeming (eicast) system in the ladle is very high, seriously restricting the service life of the coil. a novel air mist cooling method was adopted to reduce the coil temperature in this paper. firstly, the air mist generating device was.

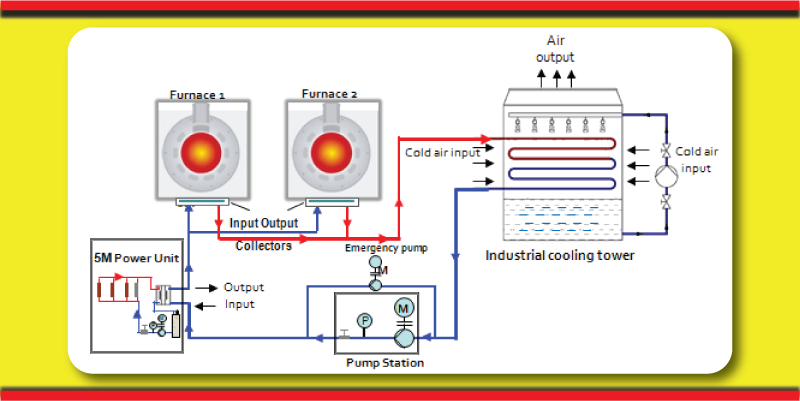

Schematic Diagram Of The Air Mist Cooling Device For The Induction Coil » section 1: coil basics the induction coil determines how effectively and efficiently a workpiece is heated. induction coils are water cooled copper conductors made of copper tubing that is readily formed into the shape of the coil for the induction heating process. induction heating coils do not themselves get hot as water flows through them. Owing to the heat transfer from high temperature liquid steel, the temperature of the coil in the electromagnetic induction controlled automated steel teeming (eicast) system in the ladle is very high, seriously restricting the service life of the coil. a novel air mist cooling method was adopted to reduce the coil temperature in this paper. firstly, the air mist generating device was. A typical induction furnace consists of several key components that work together to achieve the desired heating process. these components include a power supply unit, a coil, a crucible, and a cooling system. the schematic diagram provides a detailed overview of how these components are interconnected and operate. The cooling system mainly includes fan cooling and mist cooling. the heat generated by the device is taken away by the cooling medium to protect the equipment, which is safe and has high cooling efficiency. the channel is made of al 2 o 3 c refractory and set at the bottom of the tundish partition wall. its main function is to heat the molten.

Explanation Of How Induction Coils Are Cooled A typical induction furnace consists of several key components that work together to achieve the desired heating process. these components include a power supply unit, a coil, a crucible, and a cooling system. the schematic diagram provides a detailed overview of how these components are interconnected and operate. The cooling system mainly includes fan cooling and mist cooling. the heat generated by the device is taken away by the cooling medium to protect the equipment, which is safe and has high cooling efficiency. the channel is made of al 2 o 3 c refractory and set at the bottom of the tundish partition wall. its main function is to heat the molten.

Schematic Diagram Of The Air Cooling Device Download Scientific Diagram

Schematic Representation Of Mist Cooling Set Up Download Scientific

Comments are closed.