Tensile Test Tec Science

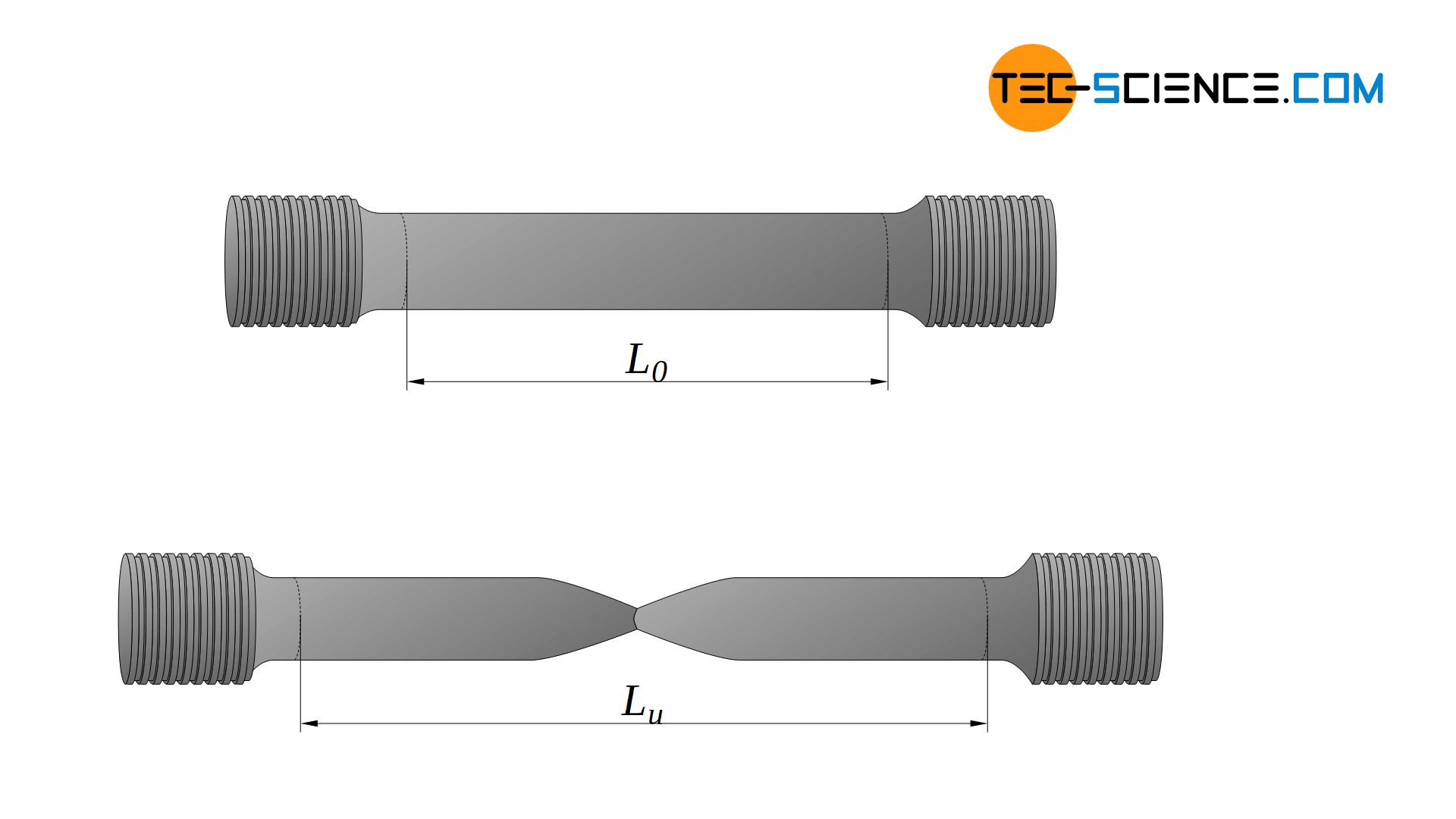

Tensile Test Tec Science The tensile test is one of the most important tests for determining material parameters in mechanical engineering! in the tensile test, a material sample with standardized geometry (tensile test specimen) is subjected to a tensile load. standardization of the geometry is intended to achieve comparability of the material parameters obtained. Due to the constant bending moment and rotation, the tensile and compressive stresses produced in the material change permanently. during one revolution, each area of the shaft is subjected to tension once and compression half a turn later. in a similar way, the reverse bend test for flat specimens was developed (“back and forth bending test”).

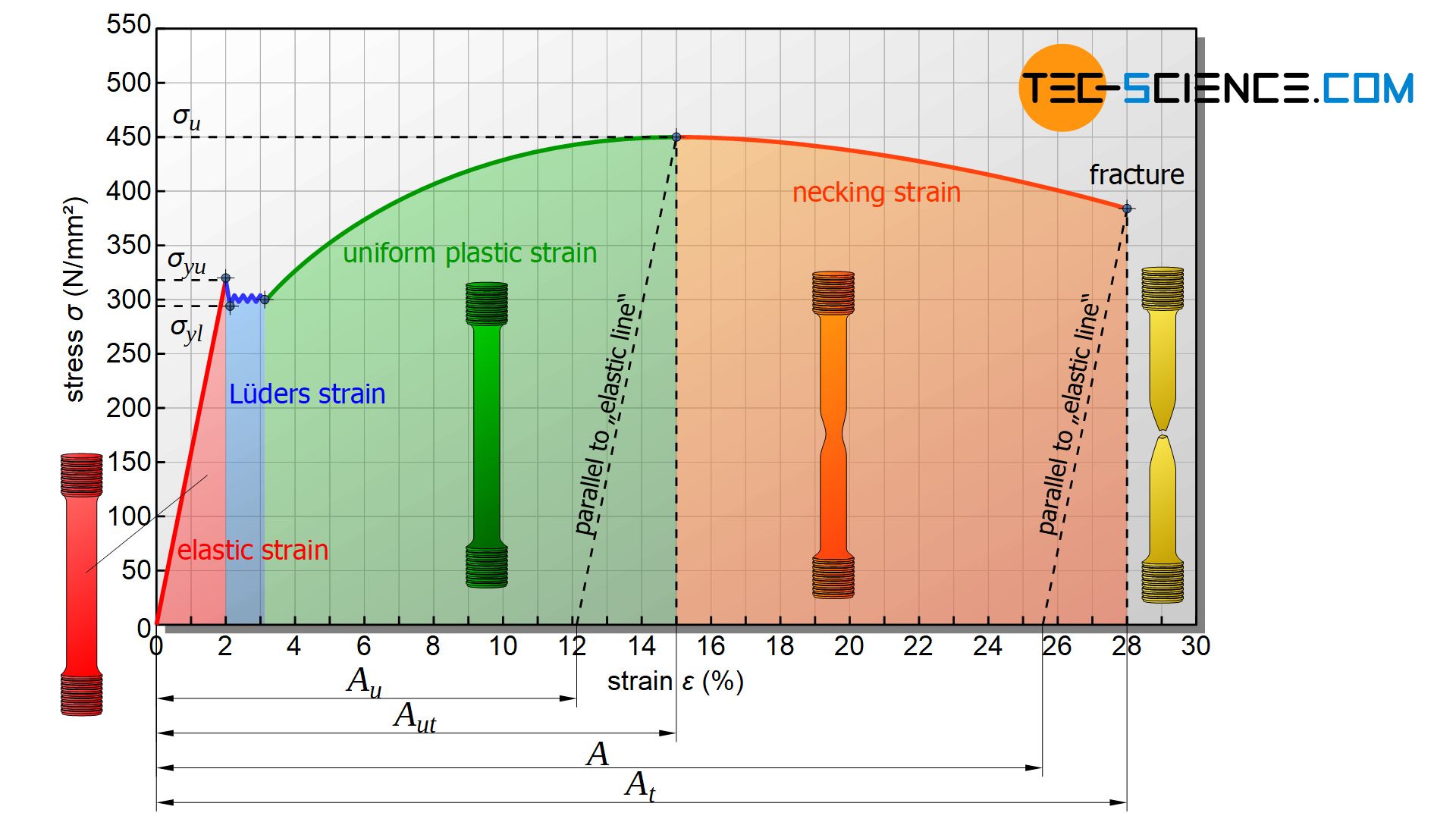

Tensile Test Tec Science Destructive material testing & non destructive testing (ndt) material testing tec science 07 13 2018 0. in destructive materials testing, the material is damaged; in non destructive materials testing, the workpiece is left undamaged. materials such as steels generally have to withstand a wide variety of loads. The tensile test measures the ability of a material to support a stress (force per unit area). the response of a tensile sample to the application of an increasing stress can be described in terms of elastic and plastic behavior. initially the sample undergoes elastic elongation as it is pulled. Figure 1. schematic of a screw driven machine. the variables involved in a tensile test are stress, strain, and time. stress is the load divided by the area while strain is the amount of deformation divided by the length over which the deformation takes place. true stress and true strain quantities can be defined. Tensile testing is used primarily to determine the mechanical behavior of a component, part or material under static, axial loading. the test method for both material testing and force measurement is similar; however the measurement results are different. a tensile test is performed to determine the tensile properties of a material or component.

Tensile Test Tec Science Figure 1. schematic of a screw driven machine. the variables involved in a tensile test are stress, strain, and time. stress is the load divided by the area while strain is the amount of deformation divided by the length over which the deformation takes place. true stress and true strain quantities can be defined. Tensile testing is used primarily to determine the mechanical behavior of a component, part or material under static, axial loading. the test method for both material testing and force measurement is similar; however the measurement results are different. a tensile test is performed to determine the tensile properties of a material or component. 5.5: tensile testing practical basics. expand collapse global location. page id. dissemination of it for the promotion of materials science (doitpoms) university of cambridge. the uniaxial tensile test is the most commonly used mechanical testing procedure. however, while it is simple in principle, there are several practical challenges, as. Tensile tests procedures for composites. if one pulls on a material until it breaks, one can find out lots of information about the various strengths and mechanical behaviors of a material. in this virtual experiment we will examine the tensile behavior of three different composite fiber materials.

Comments are closed.