The Correct Way To Drive A Forklift Truck A Safe

Forklift Safety Driving Safely Pod Posters On Demand If you are on a seated truck and do feel it tipping over, stay within the confines of the cab. brace yourself by pressing your feet on the floor and holding tight on the steering wheel or overhead guard – but take care not to get your fingers trapped between the guard and the ground. lean away from the direction the forklift is tipping. Quality operator safety training is the best way to improve forklift safety. so what does “ proper forklift training ” require? overall, osha forklift requirements state that employers must provide: formal instruction: this includes classroom based lessons that cover all 22 forklift safety topics listed in standards 1910.178(l)(3)(i) and.

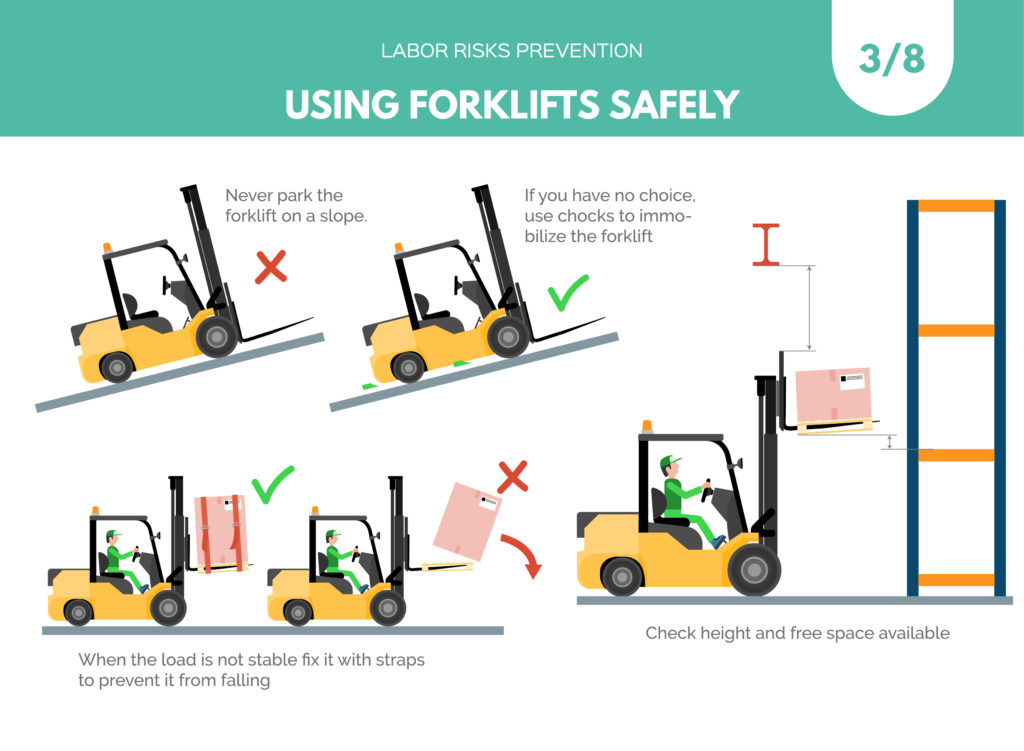

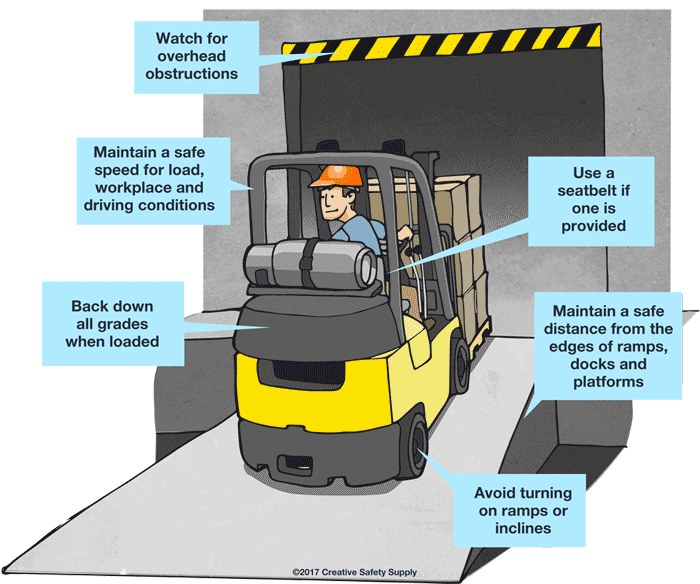

The Correct Way To Drive A Forklift Truck A Safe Drive slowly and attentively. look in the direction of, and keep a clear view of, the path of travel. always operate the forklift at a speed that will allow you to stop safely. slow down on wet or slippery floors. if the load you’re carrying obstructs your forward view, travel with the load trailing instead. 4. drive forward until the fork is completely inserted in the pallet. while your foot is on the brake, shift the gear into the forward position and release the parking brake. slowly move forward to insert the tines into the pallet openings. continue driving forward until the tines are all the way inside the pallet. This allows them to check the information shown on the gauges and warning lights. before driving a forklift, make sure the battery power, oil pressure, etc are all within normal limits. the operator should also test the signal lights and horn. lift, tilt, and other hydraulic controls can also be checked at this stage. The armrest, seat position and mirrors should be correctly adjusted and the safety belt should always be fastened. never operate a lift truck unless you are in the operator's seat and keep arms, legs and head inside the confines of the truck at all times. 5. the operating environment.

The Importance Of Forklift Safety In The Workplace Hill Law Firm This allows them to check the information shown on the gauges and warning lights. before driving a forklift, make sure the battery power, oil pressure, etc are all within normal limits. the operator should also test the signal lights and horn. lift, tilt, and other hydraulic controls can also be checked at this stage. The armrest, seat position and mirrors should be correctly adjusted and the safety belt should always be fastened. never operate a lift truck unless you are in the operator's seat and keep arms, legs and head inside the confines of the truck at all times. 5. the operating environment. Operating a forklift requires protective gear to maintain driver safety. make sure all drivers are aware of the requirements and rules of the workplace, such as wearing protective clothing like hard hats, steel toed shoes and a safety vest. always check hands and feet for grease or oil before entering the forklift. use a checklist. While operating, make sure to keep your arms and legs inside the forklift at all times. follow the three point method for mounting and dismounting. this means having two feet and a hand or two hands and a foot engaged with the vehicle at all times.

Forklift Safety Tips Rules For The Workplace Texas Motive Operating a forklift requires protective gear to maintain driver safety. make sure all drivers are aware of the requirements and rules of the workplace, such as wearing protective clothing like hard hats, steel toed shoes and a safety vest. always check hands and feet for grease or oil before entering the forklift. use a checklist. While operating, make sure to keep your arms and legs inside the forklift at all times. follow the three point method for mounting and dismounting. this means having two feet and a hand or two hands and a foot engaged with the vehicle at all times.

Comments are closed.