The Ideal Ttt Diagram Representing T T 1 Download Scientific Diagram

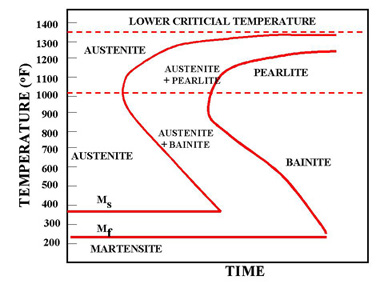

The Ideal Ttt Diagram Representing T T 1 Download ођ The ideal ttt diagrams, which were obtained using eqs. (2) and (3) are shown in fig. 3. applying scheil's additivity rule, eq. (4), and the ideal ttt diagram, eq. (3), the transformation onset can. Introduction. both temperature & time i.e. rate of cooling is taken in consideration. ttt – time temperature transformation. a plot of temperature versus log of time. steel alloy of definite composition. determines when transformations begin and end for an isothermal (constant temp.) phase transformation of a previously austenitized alloy.

The Ideal Ttt Diagram Representing T T 1 Download ођ Time temperature transformation (ttt ) diagram. t (time) t (temperature) t (transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy. Download scientific diagram | typical time–temperature transformation (ttt) diagrams (alongside continuous cooling transformation (cct) diagrams) delineate the onset of phase precipitation in. Determination of ttt diagram for eutectoid steel davenport and bain were the first to develop the ttt diagram of eutectoid steel. they determined pearlite and bainite portions whereas cohen later modified and included m s and m f temperatures for martensite. there are number of methods used to determine ttt diagrams. these are salt bath (figs. 1. Download scientific diagram | t.t.t (transformation–time–temperature) diagram for three different austenitic ferritic stainless steels [6]. from publication: heat treatment influence on the.

The Ideal Ttt Diagram Representing T T 1 Download ођ Determination of ttt diagram for eutectoid steel davenport and bain were the first to develop the ttt diagram of eutectoid steel. they determined pearlite and bainite portions whereas cohen later modified and included m s and m f temperatures for martensite. there are number of methods used to determine ttt diagrams. these are salt bath (figs. 1. Download scientific diagram | t.t.t (transformation–time–temperature) diagram for three different austenitic ferritic stainless steels [6]. from publication: heat treatment influence on the. A ttt diagram, also known as a time temperature transformation diagram, is an important tool used in metallurgy and materials science to understand the transformation behavior of materials over time and temperature. this diagram provides valuable information about the kinetics and phases that occur during cooling or heating processes, helping engineers and researchers predict the. The diagram on the lower left shows this, it is directly taken from the figure above the ttt diagram and usually not included. if we repeat the experiment at a temperature around 480 o c (900 o f), we hit the 1 % transformation line after about a tenth of a second, and the transformation is finished after about 100 seconds.

Martensite Metallurgy For Dummies A ttt diagram, also known as a time temperature transformation diagram, is an important tool used in metallurgy and materials science to understand the transformation behavior of materials over time and temperature. this diagram provides valuable information about the kinetics and phases that occur during cooling or heating processes, helping engineers and researchers predict the. The diagram on the lower left shows this, it is directly taken from the figure above the ttt diagram and usually not included. if we repeat the experiment at a temperature around 480 o c (900 o f), we hit the 1 % transformation line after about a tenth of a second, and the transformation is finished after about 100 seconds.

Comments are closed.