Time Temperature Transformation Ttt Diagram Metallurgy For Dummies

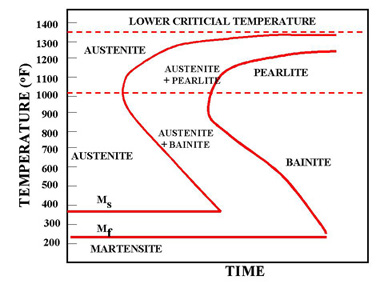

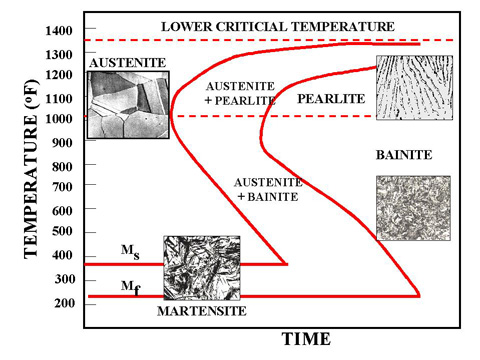

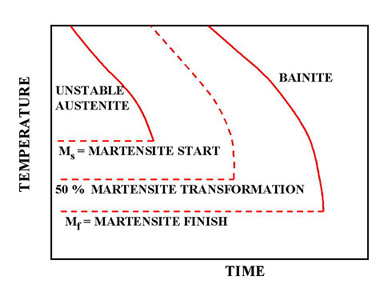

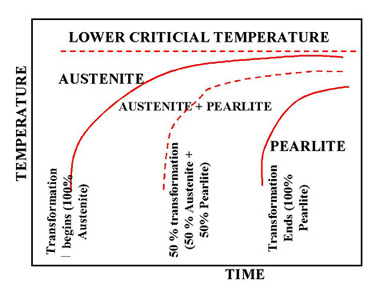

Time Temperature Transformation Ttt Diagram Metallurgy For Dummies Time temperature transformation (ttt ) diagram. t (time) t (temperature) t (transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy. Fe fe 3 c t t t diagram, adapted from callister pg. 295, fig. 10.6. the time temperature transformation curves correspond to the start and finish of transformations which extend into the range of temperatures where austenite transforms to pearlite. above 550 c, austenite transforms completely to pearlite. below 550 c, both pearlite and bainite.

Time Temperature Transformation Ttt Diagram Metallurgy For Dummies Time temperature transformation (ttt ) diagram. t (time) t (temperature) t (transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy. A ttt diagram, also known as a time temperature transformation diagram, is an important tool used in metallurgy and materials science to understand the transformation behavior of materials over time and temperature. this diagram provides valuable information about the kinetics and phases that occur during cooling or heating processes, helping engineers and researchers predict the. The ttt (time temperature transformation) diagram is a plot that shows the transformation of steel from austenite to various phases as a function of time and temperature. it is an essential tool in understanding and controlling the heat treatment process of steel. the ttt diagram is based on the principle that the phase transformation kinetics. Salt bath i (fig. 1) is maintained at austenetising temperature (780 ̊c for eutectoid steel). salt bath ii (fig. 2) is maintained at specified temperature at which transformation is to be determined (below ae1), typically 700 250°c for eutectoid steel. bath iii which is a cold water bath is maintained at room temperature.

Time Temperature Transformation Ttt Diagram Metallurgy For Dummies The ttt (time temperature transformation) diagram is a plot that shows the transformation of steel from austenite to various phases as a function of time and temperature. it is an essential tool in understanding and controlling the heat treatment process of steel. the ttt diagram is based on the principle that the phase transformation kinetics. Salt bath i (fig. 1) is maintained at austenetising temperature (780 ̊c for eutectoid steel). salt bath ii (fig. 2) is maintained at specified temperature at which transformation is to be determined (below ae1), typically 700 250°c for eutectoid steel. bath iii which is a cold water bath is maintained at room temperature. Creation of time temperature transformation diagrams and what information we can extract from themlearning goals: you describe the formation and occurrence. Phase diagrams will be covered in a separate article. the reality is that many times equilibrium cooling is not possible, not economical, or not desirable, depending on the alloy being formed. to determine what will happen to an alloy as it cools under non equilibrium conditions, metallurgists use a time temperature transformation (ttt) curve.

Time Temperature Transformation Ttt Diagram Metallurgy For Dummies Creation of time temperature transformation diagrams and what information we can extract from themlearning goals: you describe the formation and occurrence. Phase diagrams will be covered in a separate article. the reality is that many times equilibrium cooling is not possible, not economical, or not desirable, depending on the alloy being formed. to determine what will happen to an alloy as it cools under non equilibrium conditions, metallurgists use a time temperature transformation (ttt) curve.

Comments are closed.