Understanding The Ttt Diagram A Roadmap For Heat Treatment Processes

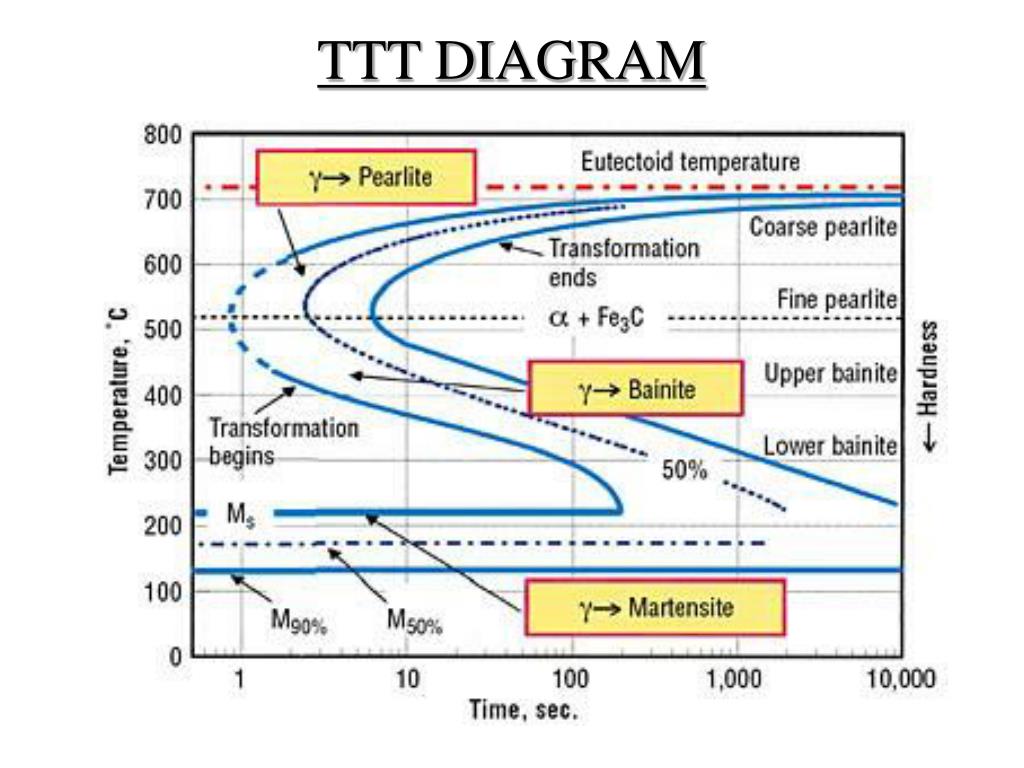

Understanding The Ttt Diagram A Roadmap For Heat Treatment Processes A ttt diagram, also known as a time temperature transformation diagram, is an important tool used in metallurgy and materials science to understand the transformation behavior of materials over time and temperature. this diagram provides valuable information about the kinetics and phases that occur during cooling or heating processes, helping engineers and researchers predict the. The ttt (time temperature transformation) diagram is a plot that shows the transformation of steel from austenite to various phases as a function of time and temperature. it is an essential tool in understanding and controlling the heat treatment process of steel. the ttt diagram is based on the principle that the phase transformation kinetics.

Understanding The Ttt Diagram A Roadmap For Heat Treatment Processes A ttt (time temperature transformation) diagram is a graphical representation of the transformation of a specific steel alloy over time and temperature during the heat treatment process. it provides information about the microstructure changes that occur as the steel is heated and cooled, allowing engineers and metallurgists to optimize the. Determination of ttt diagram for eutectoid steel davenport and bain were the first to develop the ttt diagram of eutectoid steel. they determined pearlite and bainite portions whereas cohen later modified and included m s and m f temperatures for martensite. there are number of methods used to determine ttt diagrams. these are salt bath (figs. 1. Introduction. both temperature & time i.e. rate of cooling is taken in consideration. ttt – time temperature transformation. a plot of temperature versus log of time. steel alloy of definite composition. determines when transformations begin and end for an isothermal (constant temp.) phase transformation of a previously austenitized alloy. Time temperature transformation (ttt ) diagram. t (time) t (temperature) t (transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy.

Understanding The Ttt Diagram A Roadmap For Heat Treatment Processes Introduction. both temperature & time i.e. rate of cooling is taken in consideration. ttt – time temperature transformation. a plot of temperature versus log of time. steel alloy of definite composition. determines when transformations begin and end for an isothermal (constant temp.) phase transformation of a previously austenitized alloy. Time temperature transformation (ttt ) diagram. t (time) t (temperature) t (transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy. The ttt diagram is especially useful for understanding and predicting the behavior of materials during processes such as heat treatment, welding, and quenching. by analyzing the ttt diagram, material scientists can determine the optimal temperature and time conditions for achieving desired material properties, such as increased strength. These surface modification heat treatment processes primarily aim to enhance hardness and wear resistance. conclusion. heat treatment is a critical process for modifying the properties of metals and alloys. understanding the fundamentals of heat treatment, including the phases, transformations, and ttt diagrams, is essential for achieving.

Ppt Fe Carbon Diagram Ttt Diagram Heat Treatment Processes The ttt diagram is especially useful for understanding and predicting the behavior of materials during processes such as heat treatment, welding, and quenching. by analyzing the ttt diagram, material scientists can determine the optimal temperature and time conditions for achieving desired material properties, such as increased strength. These surface modification heat treatment processes primarily aim to enhance hardness and wear resistance. conclusion. heat treatment is a critical process for modifying the properties of metals and alloys. understanding the fundamentals of heat treatment, including the phases, transformations, and ttt diagrams, is essential for achieving.

Understanding The Ttt Diagram A Roadmap For Heat Treatment Processes

Comments are closed.