Understanding Yield Strength A Comprehensive Guide Machinemfg

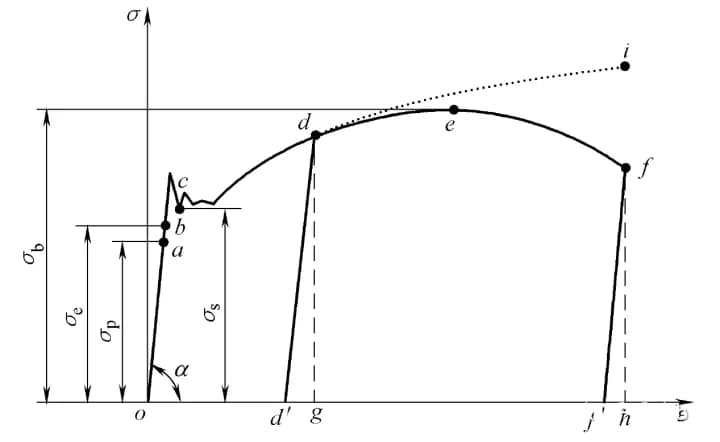

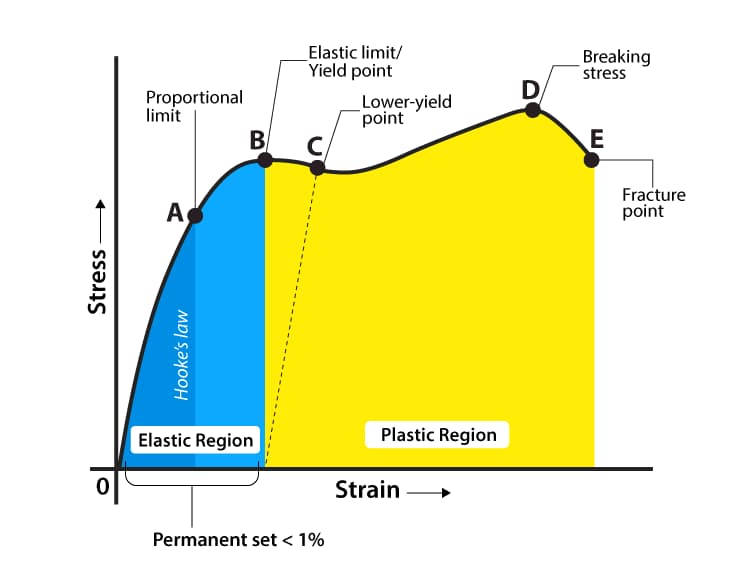

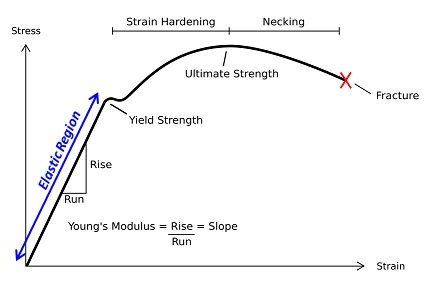

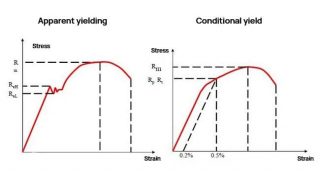

Understanding Yield Strength A Comprehensive Guide Machinemfg Yield strength: it is the yield limit of a metal material when it yields, i.e. the stress that resists slight plastic deformation. for metal materials without obvious yielding, the stress value that produces 0.2% residual deformation is specified as its yield limit, called the conditional yield limit or yield strength. Yield strength is commonly used as an evaluation index of the mechanical properties of solid materials and represents the actual service limit of the material. when the stress on a material exceeds its yield limit, plastic deformation occurs and the strain increases, rendering the material invalid and unusable. 2. type.

Understanding Yield Strength A Comprehensive Guide Machinemfg In addition, carbon can increase the steel’s cold brittleness and aging sensitivity. 2. silicon (si): silicon is added in the steelmaking process as a reductant and deoxidizer, so calm steel contains 0.15 0.30% silicon. if the silicon content in the steel exceeds 0.50 0.60%, silicon is considered an alloy element. The impact of yield strength on structural engineering and design. yield strength has a great impact on structural engineering and design. steel alloys with higher yield strengths allow engineers to create structures that are not just lighter in weight but also capable of supporting greater stresses and loads. The micro vickers test force is recommended. characteristics and application of vickers hardness. (1) the geometrical shape of the indentation is always similar, while the load can be varied. (2) the corner cone indentation contour is distinct, resulting in high measurement accuracy. Mild steel, also known as low carbon steel, is widely used due to its affordability, good formability (ease of shaping), and weldability. however, its yield strength is relatively low, typically around 200 300 mpa (30,000 45,000 psi). applications of mild steel often prioritize formability and cost effectiveness over high strength.

Discover 12 Mechanical Properties Of Sheet Metal Machinemfg The micro vickers test force is recommended. characteristics and application of vickers hardness. (1) the geometrical shape of the indentation is always similar, while the load can be varied. (2) the corner cone indentation contour is distinct, resulting in high measurement accuracy. Mild steel, also known as low carbon steel, is widely used due to its affordability, good formability (ease of shaping), and weldability. however, its yield strength is relatively low, typically around 200 300 mpa (30,000 45,000 psi). applications of mild steel often prioritize formability and cost effectiveness over high strength. Tensile strength: tensile strength represents the maximum stress a material can endure while being pulled or stretched before breaking. it measures the ultimate failure point of the material under tensile (pulling) forces. yield strength: yield strength indicates the stress at which a material begins to undergo permanent deformation under tension. Understanding the yield strength of 1045 steel is crucial for selecting the right material for your project, ensuring optimal performance, and maintaining safety standards. in this comprehensive guide, we will delve into the specifics of 1045 steel yield strength, factors that influence it, and its applications across different industries.

Detailed Explanation Of Material Yield Strength Machinemfg Tensile strength: tensile strength represents the maximum stress a material can endure while being pulled or stretched before breaking. it measures the ultimate failure point of the material under tensile (pulling) forces. yield strength: yield strength indicates the stress at which a material begins to undergo permanent deformation under tension. Understanding the yield strength of 1045 steel is crucial for selecting the right material for your project, ensuring optimal performance, and maintaining safety standards. in this comprehensive guide, we will delve into the specifics of 1045 steel yield strength, factors that influence it, and its applications across different industries.

Comments are closed.