Warehouse Picking Strategies Guide

Warehouse Picking Strategies Guide Picking speed can be measured in units per hour or orders per hour. for instance, an efficient warehouse might achieve a picking speed of 120 units per hour. order cycle time: this kpi tracks the total time from when an order is received to when it is shipped. reducing order cycle time enhances customer satisfaction and operational efficiency. Order picking strategies. the order picking methods discussed above are warehouse software (wes, wms) based and can be combined with different picking strategies in each zone depending on the technologies, order profiles and business requirements. below is a look at 5 picking strategies you should know. 1. discrete picking.

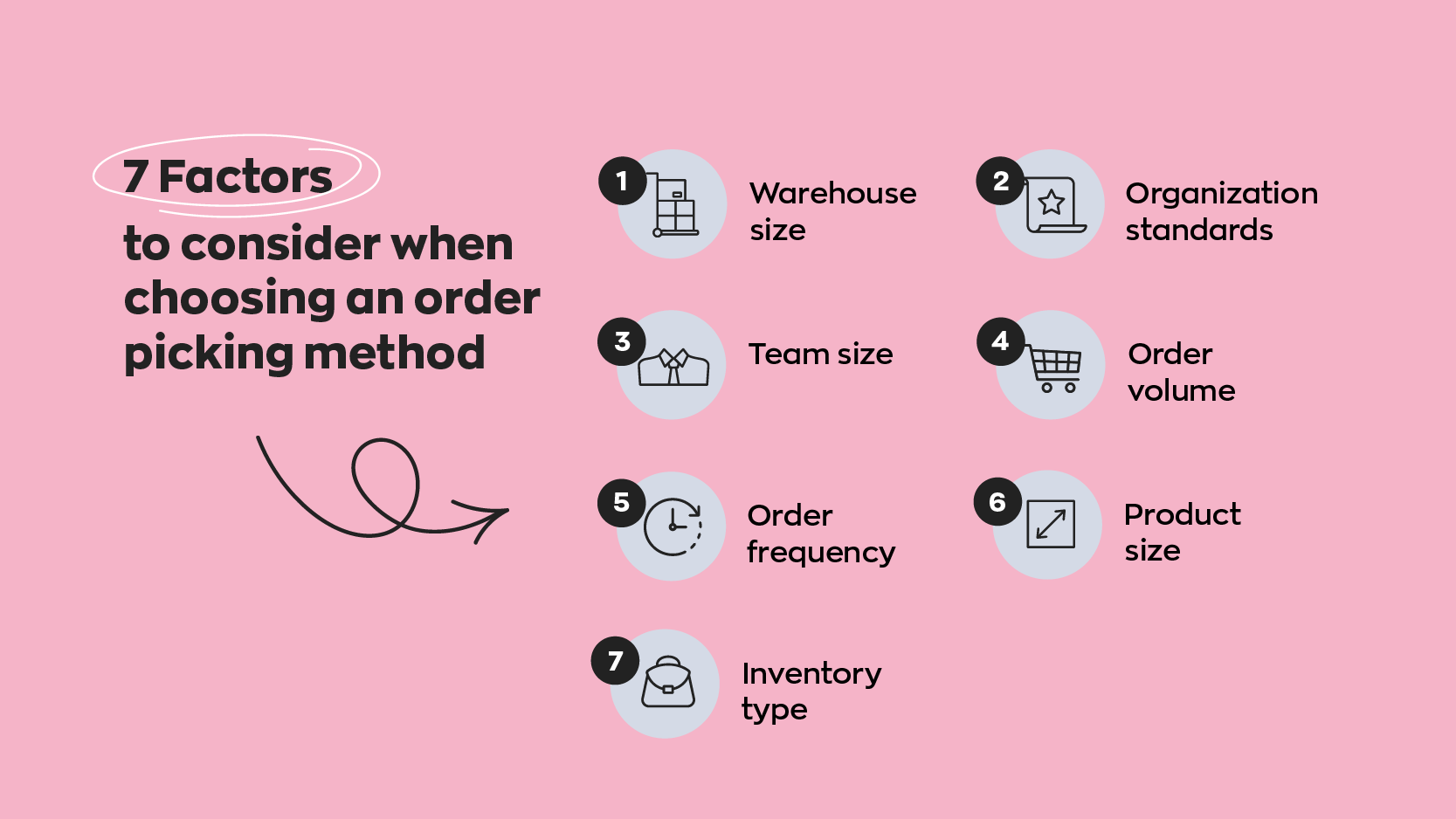

How To Choose The Best Warehouse Order Picking Method Discrete picking: in terms of complexity, discrete picking is one of the most straightforward warehouse picking types to implement. pickers retrieve one order at a time, completing it entirely before moving on to the next. this strategy is especially effective for small operations with low sku count and limited warehouse space. Warehouse design tips for order picking. order picking excellence starts by choosing the right warehouse design and flow for your business processes strategy. choose a warehouse type and flow. warehouses are usually designed to move goods in one of the layouts below (or some combination of them). Warehouse order picking tips. 1. organize with popular items in mind. “put the popular items nearest. if half of the orders you get come from 10% of the products you have in the inventory, put these items nearest the entrance of the picking area. sort according to popularity, putting least popular items at the back. Then, pinpoint areas that need improvement and determine the most suitable picking strategy. utilize key performance indicators (kpis), such as order accuracy and picking speed, to guide this process. implement software: software is the brain of the warehousing system—handling tasks like sku records, their quantities, and their storage.

Warehouse Picking Strategies Logimax Warehouse order picking tips. 1. organize with popular items in mind. “put the popular items nearest. if half of the orders you get come from 10% of the products you have in the inventory, put these items nearest the entrance of the picking area. sort according to popularity, putting least popular items at the back. Then, pinpoint areas that need improvement and determine the most suitable picking strategy. utilize key performance indicators (kpis), such as order accuracy and picking speed, to guide this process. implement software: software is the brain of the warehousing system—handling tasks like sku records, their quantities, and their storage. Consider your warehouse size, order volume, and product mix when choosing a picking strategy. ultimately, a combination of several picking methods is usually the best solution. for a complete guide to order fulfillment: strategies to improve your order fulfillment process. Step 5: implementing quality control measures. ensuring accuracy and quality in the warehouse picking process is crucial for customer satisfaction and brand integrity. implementing robust quality control measures minimizes errors, reduces returns, and ensures seamless fulfillment. key elements include thorough inspection and verification.

Comments are closed.