What Is Critical Cooling Rate In Ttt Diagram

1 Schematic Ttt Diagram The Critical Cooling Rate For Glass Formation Cooling rate b is also known as the critical cooling rate, which is represented by a cooling curve that is tangent to the nose of the ttt diagram. critical cooling rate is defined as the lowest cooling rate which produces 100% martensite while minimizing the internal stresses and distortions. figure 5. interrupted quench. in figure 5, a rapid. The diagram helps to identify the critical cooling rate required to prevent the formation of undesirable microstructures, such as excess hardness or brittleness. overall, the ttt diagram is a valuable tool in the field of materials science and engineering.

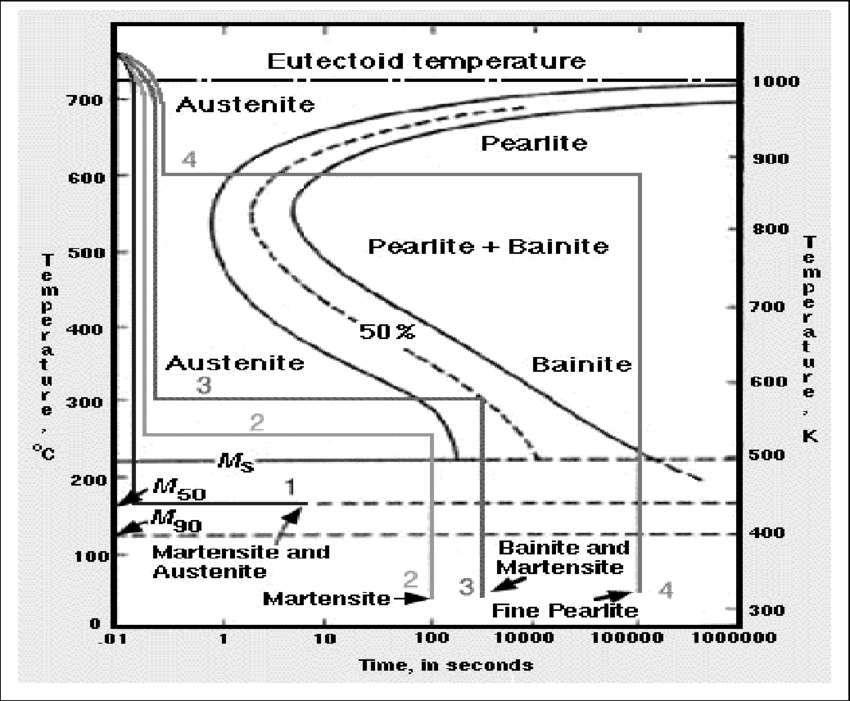

Visualization Of The Critical Scanning Rates Schema Of The Critical Determination of ttt diagram for eutectoid steel davenport and bain were the first to develop the ttt diagram of eutectoid steel. they determined pearlite and bainite portions whereas cohen later modified and included m s and m f temperatures for martensite. there are number of methods used to determine ttt diagrams. these are salt bath (figs. 1. In a ttt diagram, the critical cooling rate is the rate of cooling at which austenite transforms into 100% martensite. this transformation can be achieved by quenching the weld in water or oil. the critical cooling rate of steel? the critical cooling rate of steel is the rate of cooling that is fast enough to transform austenite into 100%. The effect of carbon content and grain size on the critical cooling rate. quenching and tempering is usually limited to steels containing more than about 0.1% carbon. figure 13.1 shows that these must be cooled at rates ranging from 100 to 2000 °c s −1, if 100% martensite is to be produced. A ttt diagram, also known as a time temperature transformation diagram, is an important tool used in metallurgy and materials science to understand the transformation behavior of materials over time and temperature. this diagram provides valuable information about the kinetics and phases that occur during cooling or heating processes, helping engineers and researchers predict the.

Ttt Diagrams And Critical Cooling Rates To Characterize Metastability The effect of carbon content and grain size on the critical cooling rate. quenching and tempering is usually limited to steels containing more than about 0.1% carbon. figure 13.1 shows that these must be cooled at rates ranging from 100 to 2000 °c s −1, if 100% martensite is to be produced. A ttt diagram, also known as a time temperature transformation diagram, is an important tool used in metallurgy and materials science to understand the transformation behavior of materials over time and temperature. this diagram provides valuable information about the kinetics and phases that occur during cooling or heating processes, helping engineers and researchers predict the. The rate of cooling necessary to harden the part is called the critical cooling rate. it is the minimum cooling rate that will achieve the maximum hardness. if the part is cooled at higher rates than the critical cooling rate, no additional hardness will be achieved, but may cause excessive distortion and possibly cracking. The critical cooling rate can be estimated after depicting the time temperature transformation (ttt) diagram of an alloy 5. therefore, it is necessary to establish a method to predicting the ttt.

What Is Critical Cooling Rate In Ttt Diagram Iransmarts The rate of cooling necessary to harden the part is called the critical cooling rate. it is the minimum cooling rate that will achieve the maximum hardness. if the part is cooled at higher rates than the critical cooling rate, no additional hardness will be achieved, but may cause excessive distortion and possibly cracking. The critical cooling rate can be estimated after depicting the time temperature transformation (ttt) diagram of an alloy 5. therefore, it is necessary to establish a method to predicting the ttt.

Heat Treatment Of Steels I

Comments are closed.