What Is The Difference Between A Closed Loop Open Loop Chilling System Industrial Water Chiller

What Is The Difference Between A Closed Loop Open Loop Chilling Industrial water chiller a division of t. j. snow specializes in self contained, air cooled recirculating chillers from 1 2 ton to 150 ton capacity.indus. Open loop liquid cooling can be used to cool your cpu, gpu, motherboard vrms, and ram, enabling you to push the entire system to its limits. when it comes to compatibility and form factor with an open loop it is somewhat complicated vs closed loop coolers. radiators come in similar sizes for an open loop system but come in sizes as large as 480mm.

Difference Between Open Loop Closed Loop Systems In the realm of industrial and commercial chiller, not all chiller systems are created equal, and the choice between a closed loop and an open loop chiller system can significantly impact operational efficiency, cost effectiveness, and environmental sustainability. Cost considerations. cost is a significant factor for building managers: open loop: lower initial installation costs but may require higher maintenance due to contamination and scaling. closed loop: higher upfront costs but lower long term maintenance expenses due to cleaner water circulation. The same is true for water treatment chemicals and or systems; closed loop technology can help to dramatically reduce or even eliminate the need for chemical treatment of system fluids. while open loop cooling towers reject heat in a smaller footprint than closed loop fluid coolers (due to the process fluid being cooled via direct latent heat. A closed loop chiller system reuses coolant instead of releasing it as waste. these systems prevent water and coolant from receiving direct air contact with anything outside the chiller system itself. this is a key difference between closed loop and open loop chillers, where the chiller is hooked up to a cooling tower that allows direct air to.

Closed Loop Chiller System Vs Open Loop Chiller System Industrial The same is true for water treatment chemicals and or systems; closed loop technology can help to dramatically reduce or even eliminate the need for chemical treatment of system fluids. while open loop cooling towers reject heat in a smaller footprint than closed loop fluid coolers (due to the process fluid being cooled via direct latent heat. A closed loop chiller system reuses coolant instead of releasing it as waste. these systems prevent water and coolant from receiving direct air contact with anything outside the chiller system itself. this is a key difference between closed loop and open loop chillers, where the chiller is hooked up to a cooling tower that allows direct air to. Closed loop heating is a method to accurately control and maintain temperature during the process. this method contains a feedback loop in which a control system receives feedback from the process and develops a response to achieve stability. it can be used for many heating applications and is an effective control method in process heating due. Long known as water hogs, resistance welders are widely used in factories that manufacture products made from sheet metal and wire. sub categories of the resistance welding process include spot welding, projection welding, seam welding, butt welding and flash welding. an adequate flow of cooling water is one of the most important variables of.

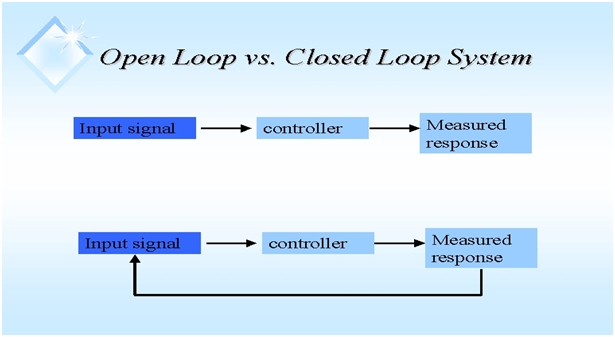

Difference Between Open Loop Closed Loop System The Engineering Closed loop heating is a method to accurately control and maintain temperature during the process. this method contains a feedback loop in which a control system receives feedback from the process and develops a response to achieve stability. it can be used for many heating applications and is an effective control method in process heating due. Long known as water hogs, resistance welders are widely used in factories that manufacture products made from sheet metal and wire. sub categories of the resistance welding process include spot welding, projection welding, seam welding, butt welding and flash welding. an adequate flow of cooling water is one of the most important variables of.

Comments are closed.