What To Include In Your Engineering Drawing Fast Radius

What To Include In Your Engineering Drawing Fast Radius Fast radius proprietary information the information contained in this drawing is the sole property of fast radius. any reproduction in part or as a whole without the written permission of fast radius is prohibited. a a b b c c d d 4 4 3 3 2 2 1 1 unless otherwise specified dimensions are in inches tolerances are: angles: .5 2 place decimal: .01. On every engineering drawing, there are a few must haves, including: dimensions and tolerances: include any dimensions and tolerances that are necessary for producing the part in your drawing. for cnc parts, it is customary to include all of the part’s dimensions in the drawing. however, for injection molded or additively manufactured parts.

What To Include In Your Engineering Drawing Fast Radius Figure 2 an isometric drawing. any engineering drawing should show everything: a complete understanding of the object should be possible from the drawing. if the isometric drawing can show all details and all dimensions on one drawing, it is ideal. one can pack a great deal of information into an isometric drawing. Engineering drawings are technical diagrams and symbols used by engineers to accurately represent and communicate complex structures or systems. these drawings include precise measurements, material specifications and procedures, necessary for designing, producing, or troubleshooting technical applications. Here’s a look at some of the most common types of engineering drawings: 1. assembly drawings. these drawings show how multiple parts fit together to form a complete unit. they depict the components of a machine or a system in their relative positions and are essential in guiding the assembly process. Engineering working drawings basics. engineering graphics is an effective way of communicating technical ideas and it is an essential tool in engineering design where most of the design process is graphically based. engineering graphics is used in the design process for visualization, communication, and documentation.

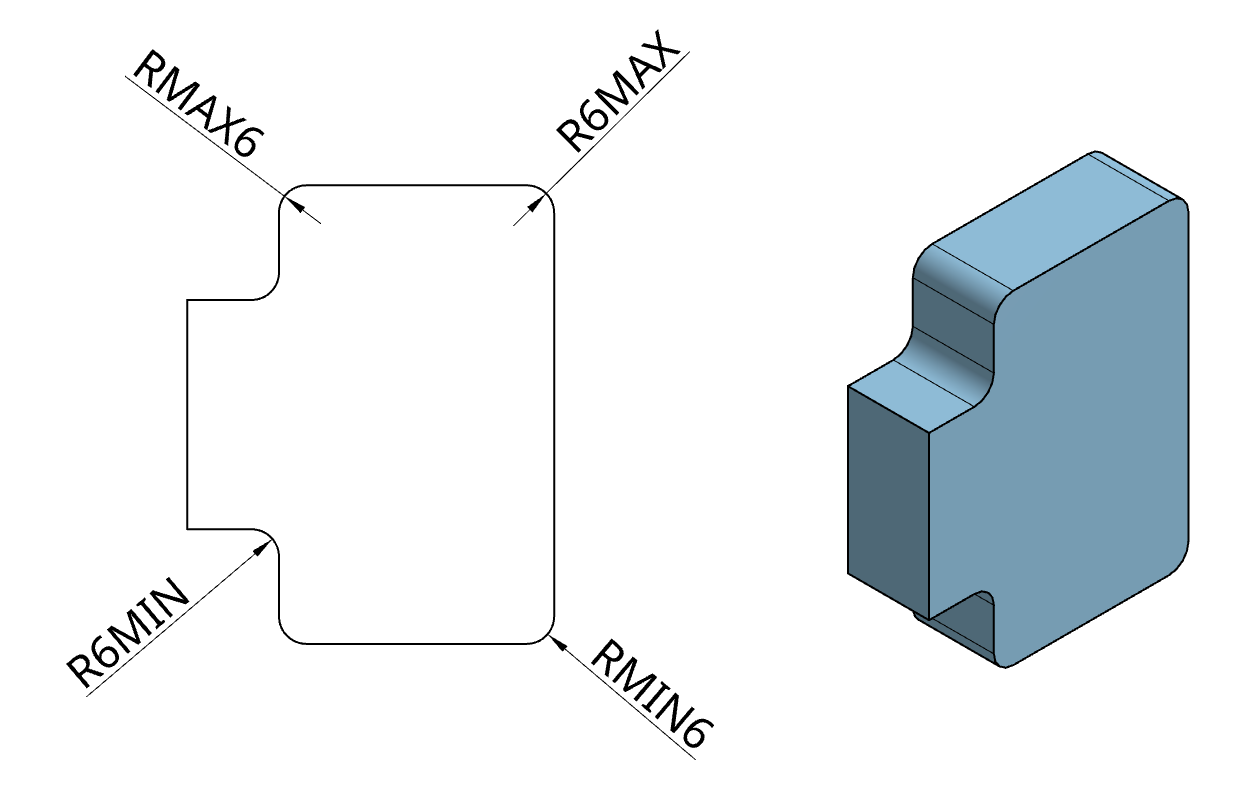

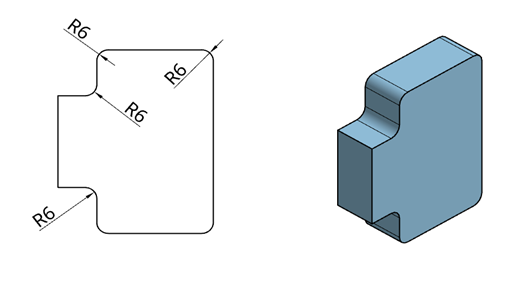

Radii Radius In Technical Drawings Here’s a look at some of the most common types of engineering drawings: 1. assembly drawings. these drawings show how multiple parts fit together to form a complete unit. they depict the components of a machine or a system in their relative positions and are essential in guiding the assembly process. Engineering working drawings basics. engineering graphics is an effective way of communicating technical ideas and it is an essential tool in engineering design where most of the design process is graphically based. engineering graphics is used in the design process for visualization, communication, and documentation. An engineering drawing (also named as mechanical drawing, manufacturing blueprints, drawings, dimensional prints, and more) refers to one of the technical drawings, which helps to define engineering products’ requirements. basically, this type of drawing aims at clearly capturing all the geometric features of products and their components. Gd&t and the quality engineer. as a quality engineer you will be expected to be able to read and interpret engineering drawings and the gd&t associated with that drawing. this will allow you to understand the intent of the product designer, which will allow you to assess the conformance of a unit coming off of your production line.

Radii Radius In Technical Drawings An engineering drawing (also named as mechanical drawing, manufacturing blueprints, drawings, dimensional prints, and more) refers to one of the technical drawings, which helps to define engineering products’ requirements. basically, this type of drawing aims at clearly capturing all the geometric features of products and their components. Gd&t and the quality engineer. as a quality engineer you will be expected to be able to read and interpret engineering drawings and the gd&t associated with that drawing. this will allow you to understand the intent of the product designer, which will allow you to assess the conformance of a unit coming off of your production line.

Comments are closed.